Two-component polyurethane sealant

A two-component polyurethane and sealant technology, applied in polyurea/polyurethane adhesives, adhesive types, other chemical processes, etc., can solve the problems of unsatisfactory, high price, long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

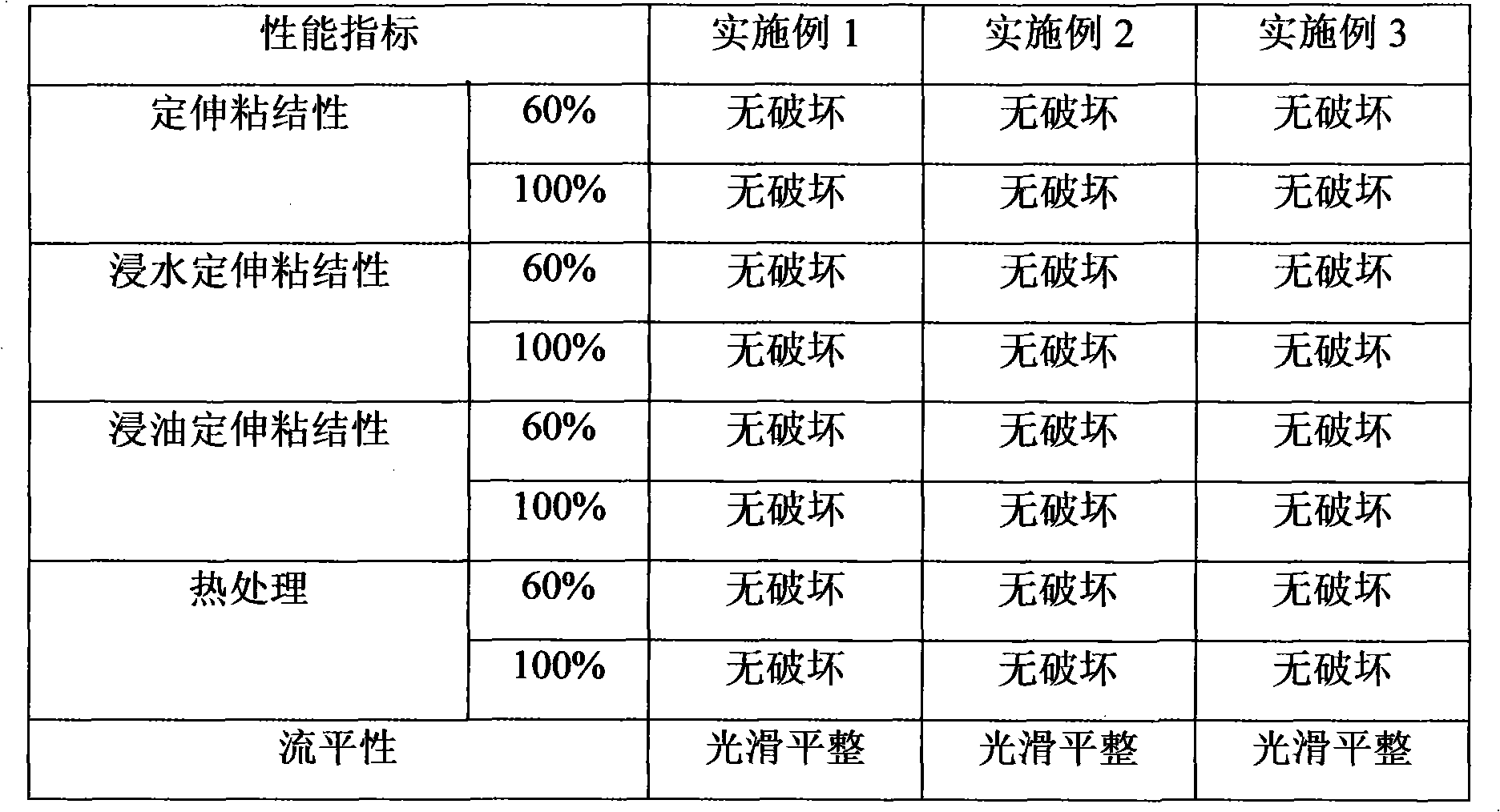

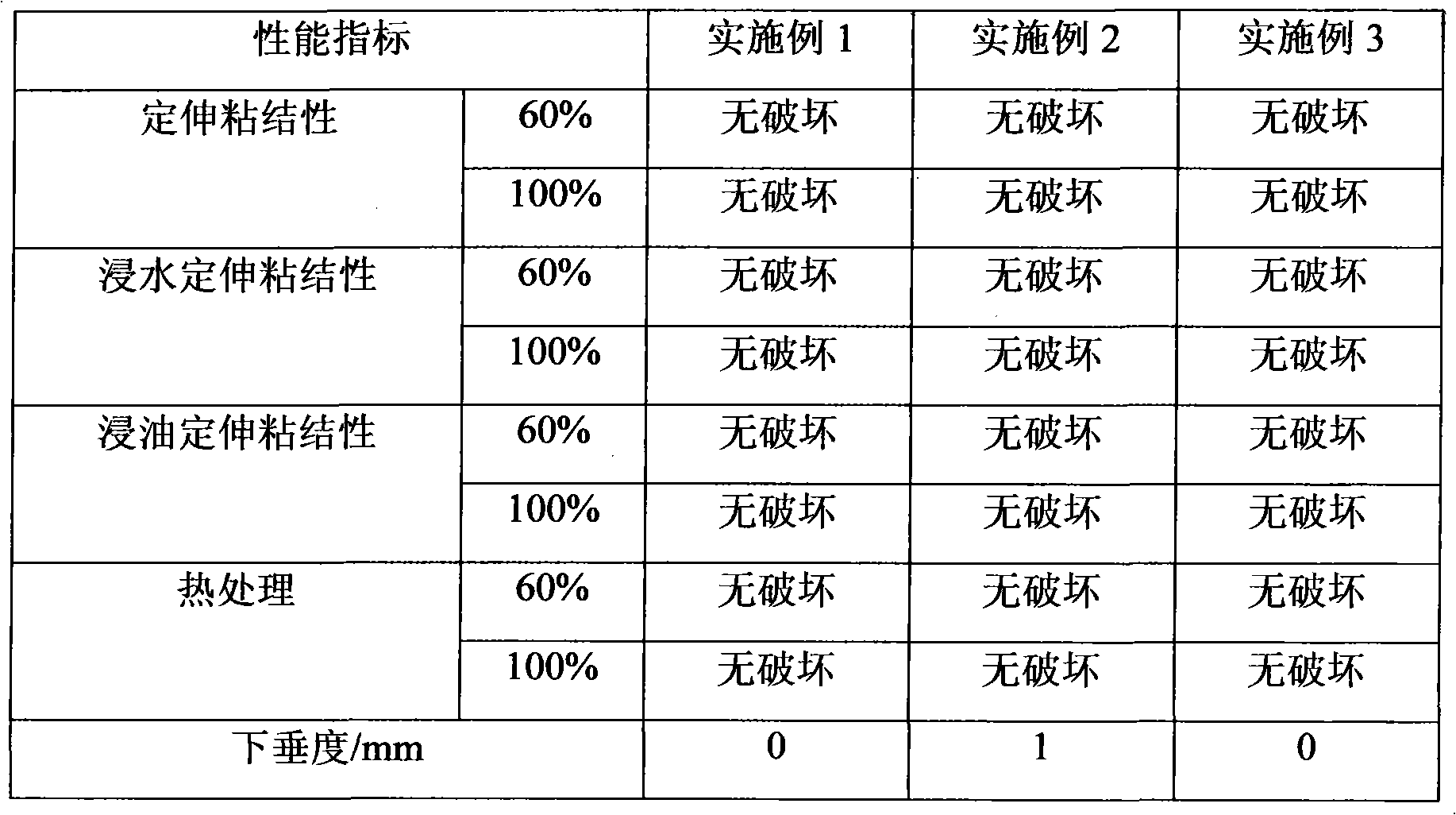

Examples

Embodiment 1

[0017] Add 253g of polyether diol into a 1000mL four-necked reaction flask, raise the temperature to 100°C-120°C for 4h in vacuum, cool down below 60°C, add 2.5g of dioctyl phthalate and 5.5g of organic bentonite, stir for 30min Finally, add 30g of diisocyanate, heat up slowly, control the temperature at 80-85°C, react under vacuum for 2.5h, lower the temperature below 60°C, add 50g of plasticizer, vacuum degassing for 1h, and discharge to obtain component A .

[0018] Add 84g polyether triol, 28g castor oil, 440g plasticizer, and 2.6g dispersant to a 1000mL four-necked reaction flask, raise the temperature to 80°C, add 19g organic bentonite, 12g MOCA, 2.6g carbon black, and 129g active calcium hydrogen , fully stirred evenly, heated up to 100°C-120°C for 4 hours in vacuum dehydration, lowered the temperature below 60°C, added 6g of dibutyltin dilaurate, 0.6g of coupling agent, 1.3g of defoamer, stirred fully for 30min, mixed evenly, and discharged , to obtain component B.

Embodiment 2

[0020] Add 253g of polyether diol into a 1000mL four-necked reaction flask, raise the temperature to 100°C-120°C for 4h in vacuum, cool down below 60°C, add 2.5g of dioctyl phthalate and 5.5g of organic bentonite, stir for 30min Finally, add 30g of diisocyanate, heat up slowly, control the temperature at 80-85°C, react under vacuum for 2.5h, lower the temperature below 60°C, add 50g of plasticizer, vacuum degassing for 1h, and discharge to obtain component A .

[0021] Add 65g polyethertriol, 22g castor oil, 343g plasticizer, and 2g dispersant to a 1000mL four-necked reaction flask, raise the temperature to 80°C, add 5g organic bentonite, 8g MOCA, 2g carbon black, and 80g active calcium hydrogen, fully Stir evenly, heat up to 100°C to 120°C for vacuum dehydration for 4 hours, cool down below 60°C, add 4g of dibutyltin dilaurate, 0.44g of coupling agent, 1g of defoamer, stir fully for 30min, mix evenly, and discharge to obtain B component.

Embodiment 3

[0023] Add 228g of polyether diol into a 1000mL four-necked reaction flask, heat up to 100°C to 120°C for 4h in vacuum, cool down below 60°C, add 2.25g of dioctyl phthalate and 5g of organic bentonite, stir for 30min , add 27g of diisocyanate, heat up slowly, control the temperature at 80-85°C, react under vacuum for 2.5h, lower the temperature below 60°C, add 48g of plasticizer, degas in vacuum for 1h, and discharge to obtain component A.

[0024] Add 65g polyether triol, 22g castor oil, 343g plasticizer, and 2g dispersant to a 1000mL four-necked reaction flask, heat up to 80°C, add 15g organic bentonite, 9g MOCA, 2g carbon black, and 130g active calcium hydrogen, fully Stir evenly, heat up to 100°C to 120°C for vacuum dehydration for 4 hours, cool down below 60°C, add 4g of dibutyltin dilaurate, 0.44g of coupling agent, 1g of defoamer, stir fully for 30min, mix evenly, and discharge to obtain B component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com