Automatic water oxygen-rich composite floating bed for strengthening biological carbon and phosphorous removal effect

A technology for biological denitrification and water body, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Improve the self-purification function and enhance the effect of nitrogen and phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

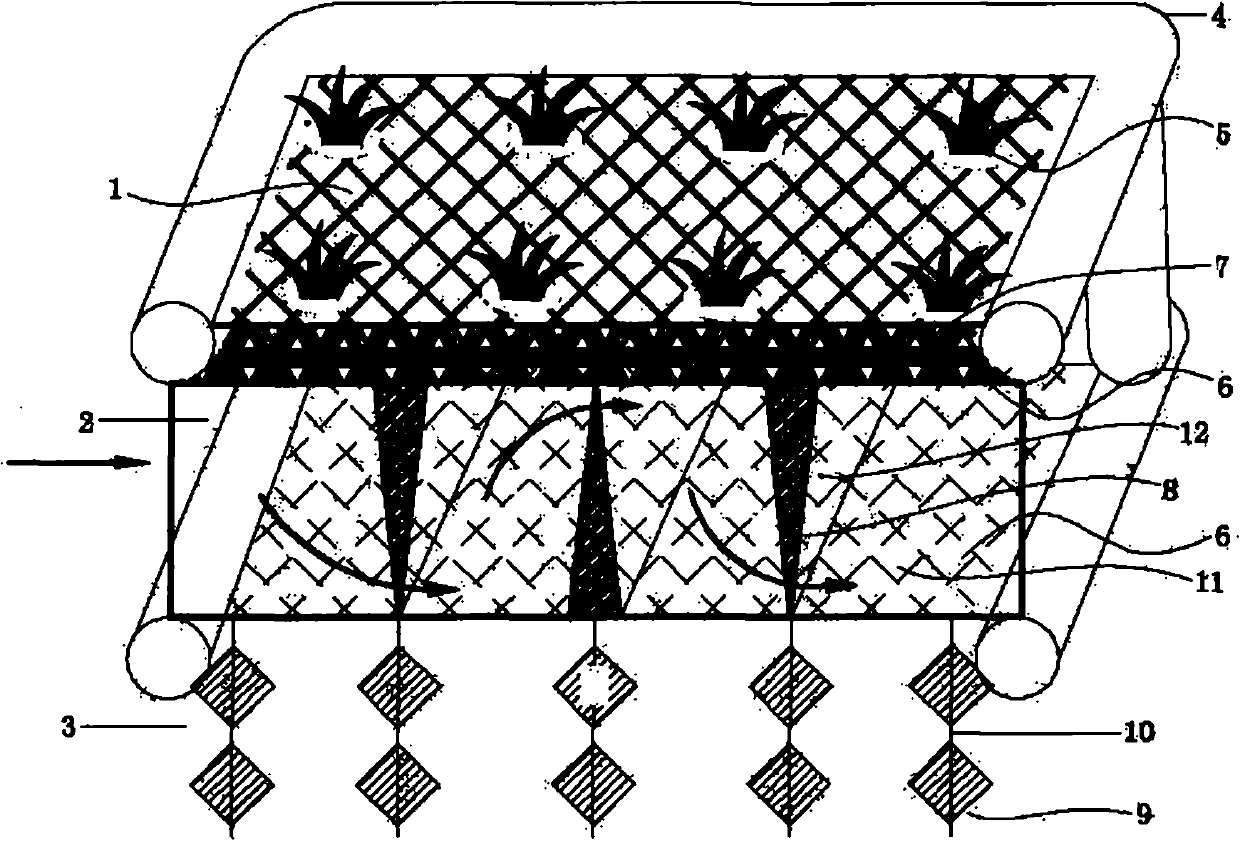

[0025] (1) make floating bed frame 4 with bamboo or wooden strip, the diameter of bamboo or wooden strip is 3-6cm, and the length, width and height of frame 4 are successively 60-75cm, 40-45cm, 25-35cm, between each part Connect and fix with iron wire or three-hole bowl joint.

[0026] (2) Fix one deck stainless steel wire mesh 6 with tie wire or cable ties at the top, bottom and surroundings of the frame 4, the wire diameter is 0.8mm, and the mesh is 13mm.

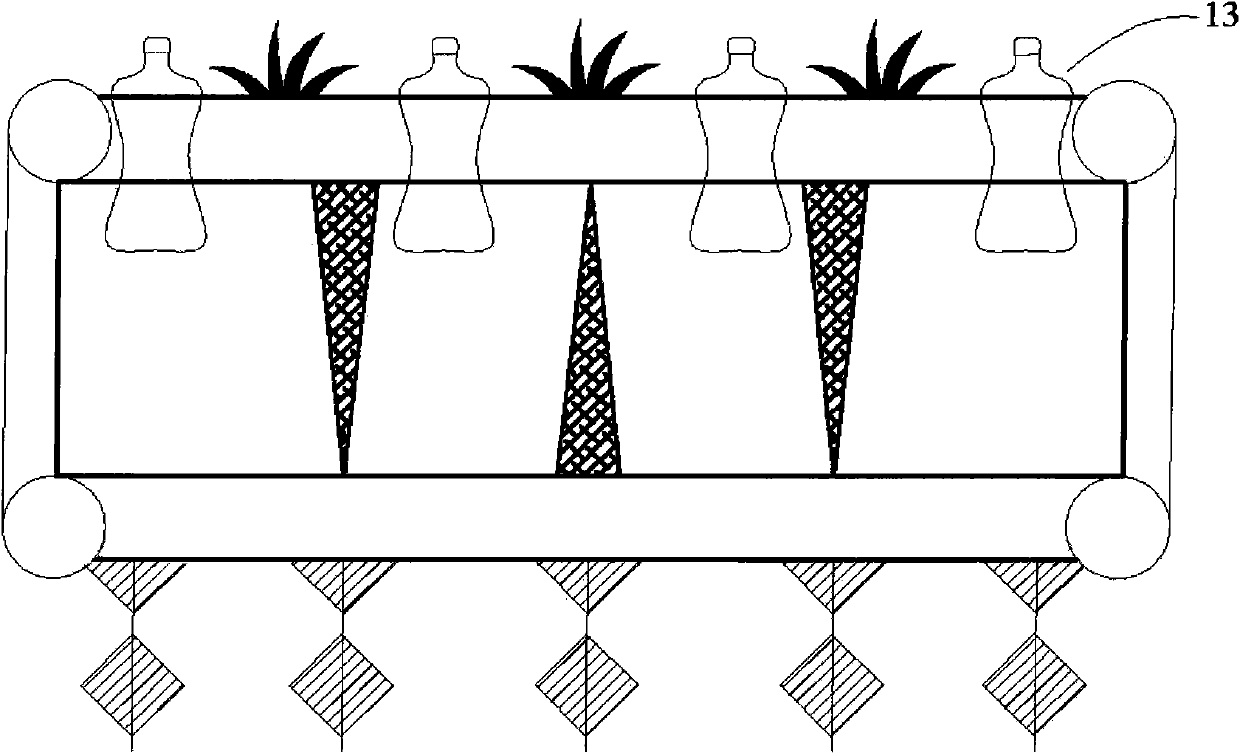

[0027] (3) if figure 1 As shown, the oxygen-enriched multistage aerobic-anaerobic reaction unit 2 is composed of an aerobic zone 11 and an anaerobic zone 12 in the middle of the frame 4 separated by a separator 8 . Use stainless steel wire mesh to form a straight triangular prism separator 8, and line the inner surface with a layer of non-woven fabric to prevent the filler from leaking, and leave one end open for filling. The filler is a mixture of activated carbon and zeolite with a volume ratio of 1:1. The particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com