Method for producing Dafeng pills for treating low back pain by utilizing micro-powder technology

A micro-powder technology, low back pain technology, applied in the medical field, can solve the problem of poor treatment effect of Dafeng Pills, achieve the effect of shortening the drug onset time, improving curative effect, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

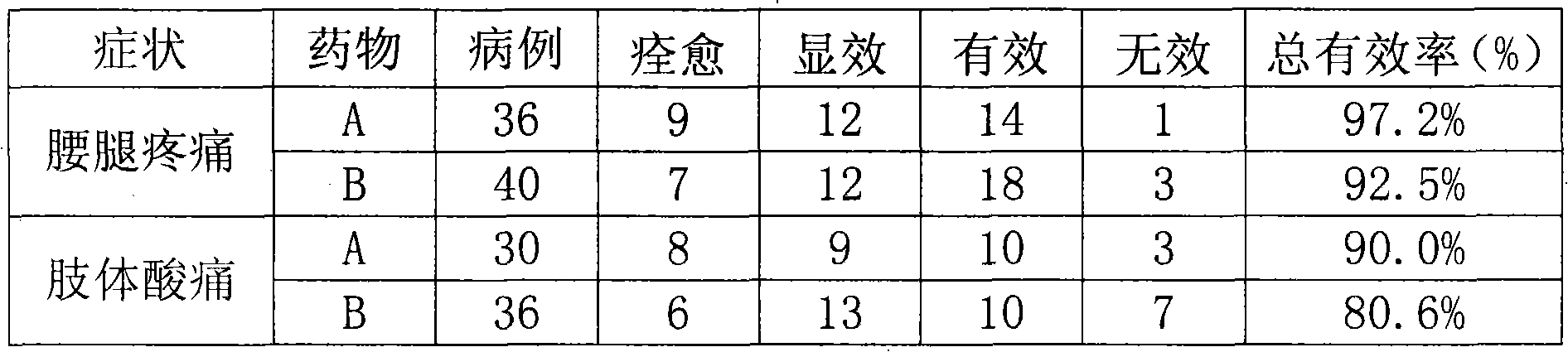

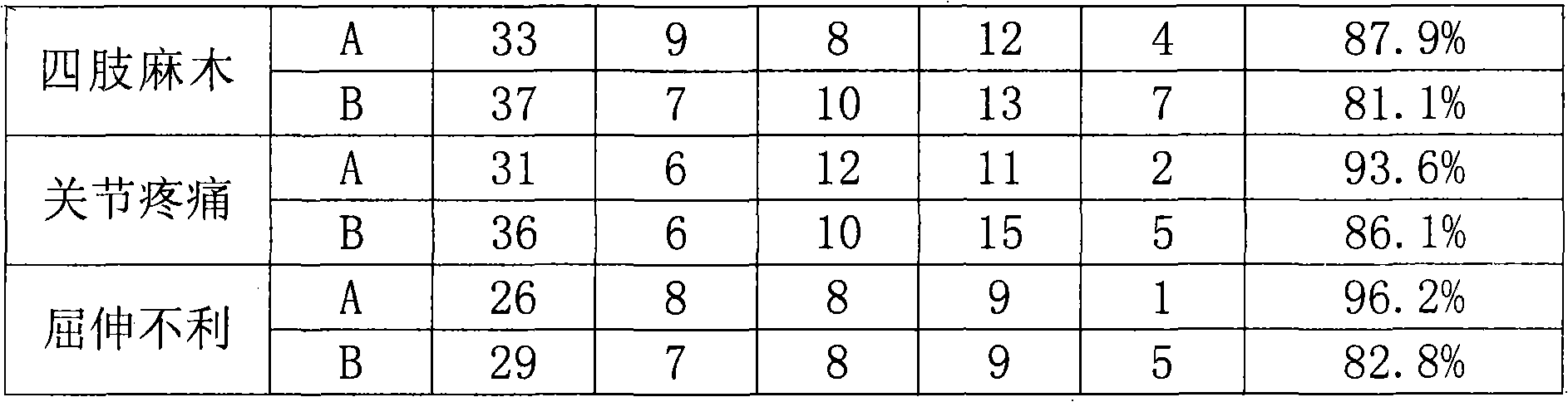

Examples

Embodiment 1

[0008] It is made from 25% of fungus, 18% of angelica, 13% of white peony, 4% of Achyranthes bidentata, 4% of papaya, 4% of platycodon, 4% of Eucommia, 8% of herb and 20% of herb. Rinse and wash with water respectively, place in an oven, dry at 45°C, mix and pulverize through a sieve with an aperture of 75 μm, sterilize at 115°C for 15 minutes, let cool, and pass through a sieve with an aperture of 75 μm to obtain a fine powder of the mixture with a diameter of 0.1-75 μm. Add rice vinegar with 30% of the weight of the micropowder into the micropowder, mix evenly, pelletize, and then dry at 70° C. to obtain final product.

Embodiment 2

[0010] It is made from 30% of fungus, 12% of angelica, 7% of white peony, 6% of Achyranthes bidentata, 6% of papaya, 6% of bellflower, 6% of Eucommia, 9% of atractylodes atractylodes and 18% of herb. Rinse and wash with water respectively, place in an oven, dry at 50°C, mix and pulverize through a sieve with an aperture of 75 μm, sterilize at 120°C for 20 minutes, let cool, and pass through a sieve with an aperture of 75 μm to obtain a fine powder of the mixture with a diameter of 0.1-75 μm. Add rice vinegar with 32% of the weight of the micropowder into the micropowder, mix evenly, make pellets, and then dry at 75°C to obtain final product.

Embodiment 3

[0012] It is made from 34% fungus, 15% angelica, 10% white peony root, 5% achyranthes bidentata, 5% papaya, 5% bellflower, 5% Eucommia ulmoides, 9% atractylodes atractylodes and 12% herb. Rinse and wash with water respectively, place in an oven, dry at 55°C, mix and pulverize through a sieve with an aperture of 75 μm, sterilize at 125°C for 25 minutes, let cool, and pass through a sieve with an aperture of 75 μm to obtain a fine powder of the mixture with a diameter of 0.1-75 μm. Add rice vinegar with 34% of the weight of the micropowder into the micropowder, mix evenly, make pellets, and then dry at 80°C to obtain final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com