Lithium ion cylinder battery welding clamp and use method thereof

A cylindrical battery, welding fixture technology, applied in welding equipment, non-electric welding equipment, battery pack components and other directions, can solve problems such as erosion, and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates shown in the drawing, is described in detail as follows:

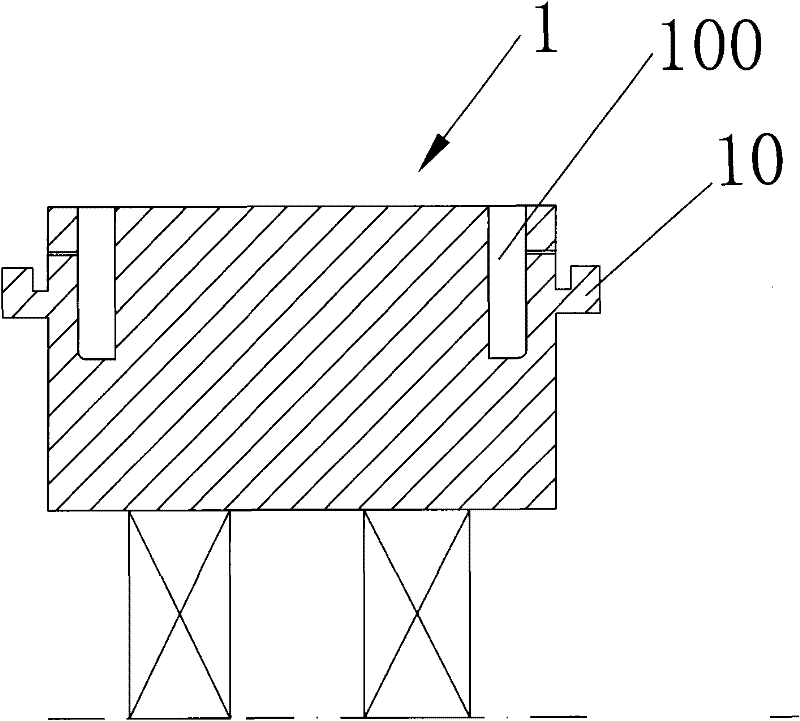

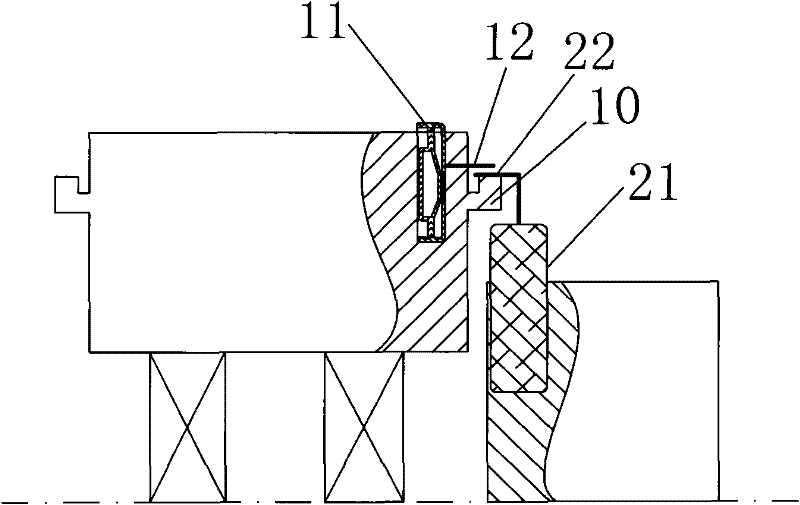

[0036] see Figure 1 ~ Figure 4 , the lithium ion cylindrical battery welding jig of the present invention, the lithium ion cylindrical battery comprises a battery cap 11 and a battery core 21, the battery cap 11 has a cap tab 12, the battery core 21 has a battery tab 22, the welding fixture It mainly includes a cap clamp 1 and a battery cell clamp 2, wherein, the upper ring of the cap clamp 1 is provided with four pallets 10, and every two adjacent pallets 10 are arranged at 90 degrees, corresponding to each pallet 10 on the cap clamp 1 There are also four cap slots 100 at the position for accommodating the battery cap 11. The cap 11 has a cap tab 12. When the battery cap 11 is located in the cap slot 100, adjust the cap tab 12 so that it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com