Digital vortex thermo-motive generation device

A power generation device and thermal power technology, which is applied to steam engine devices, machines/engines, steam applications, etc., can solve problems such as low workload rate, low seasonal energy efficiency ratio, lack of low-temperature heat source heat collection, etc., to reduce operating costs and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

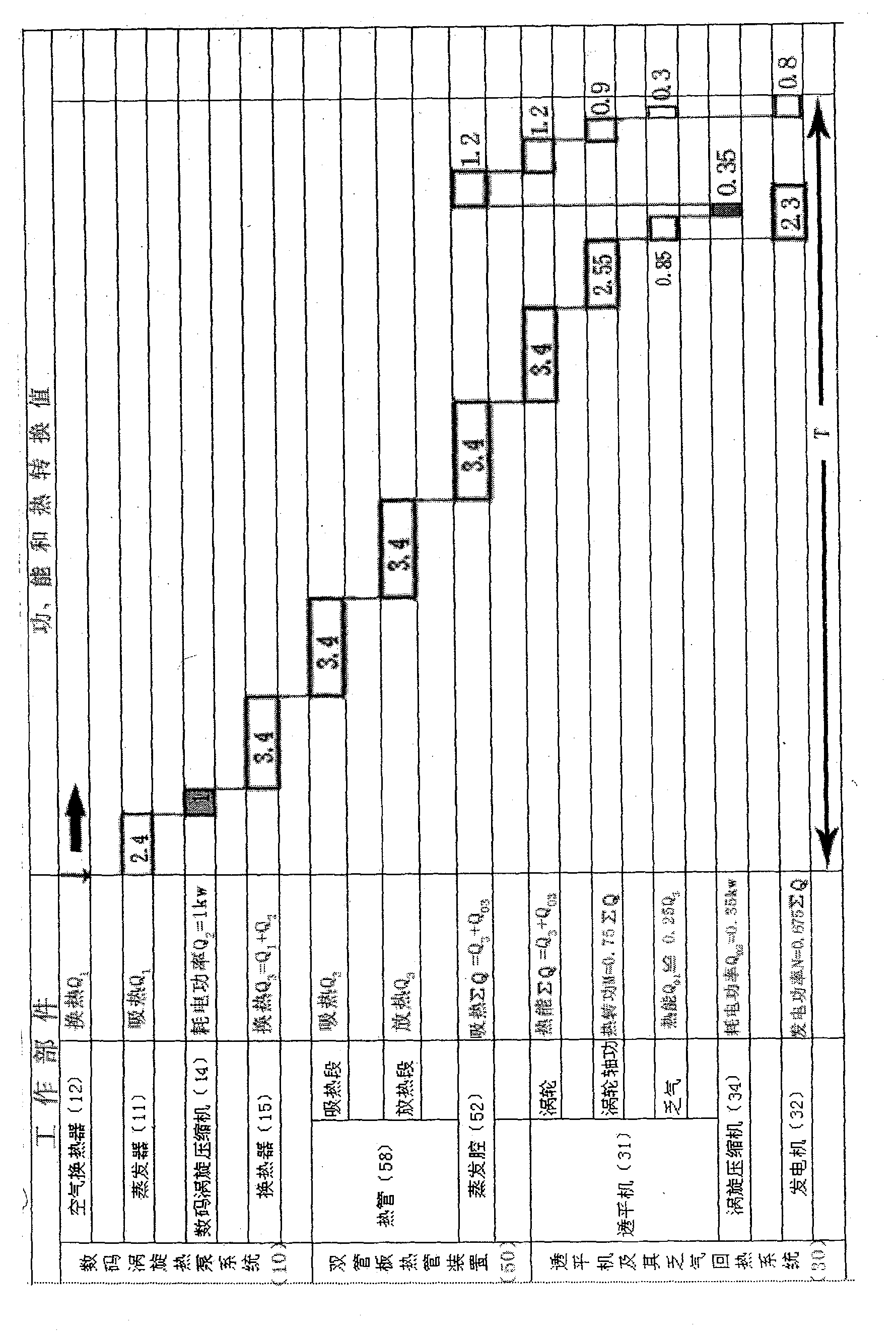

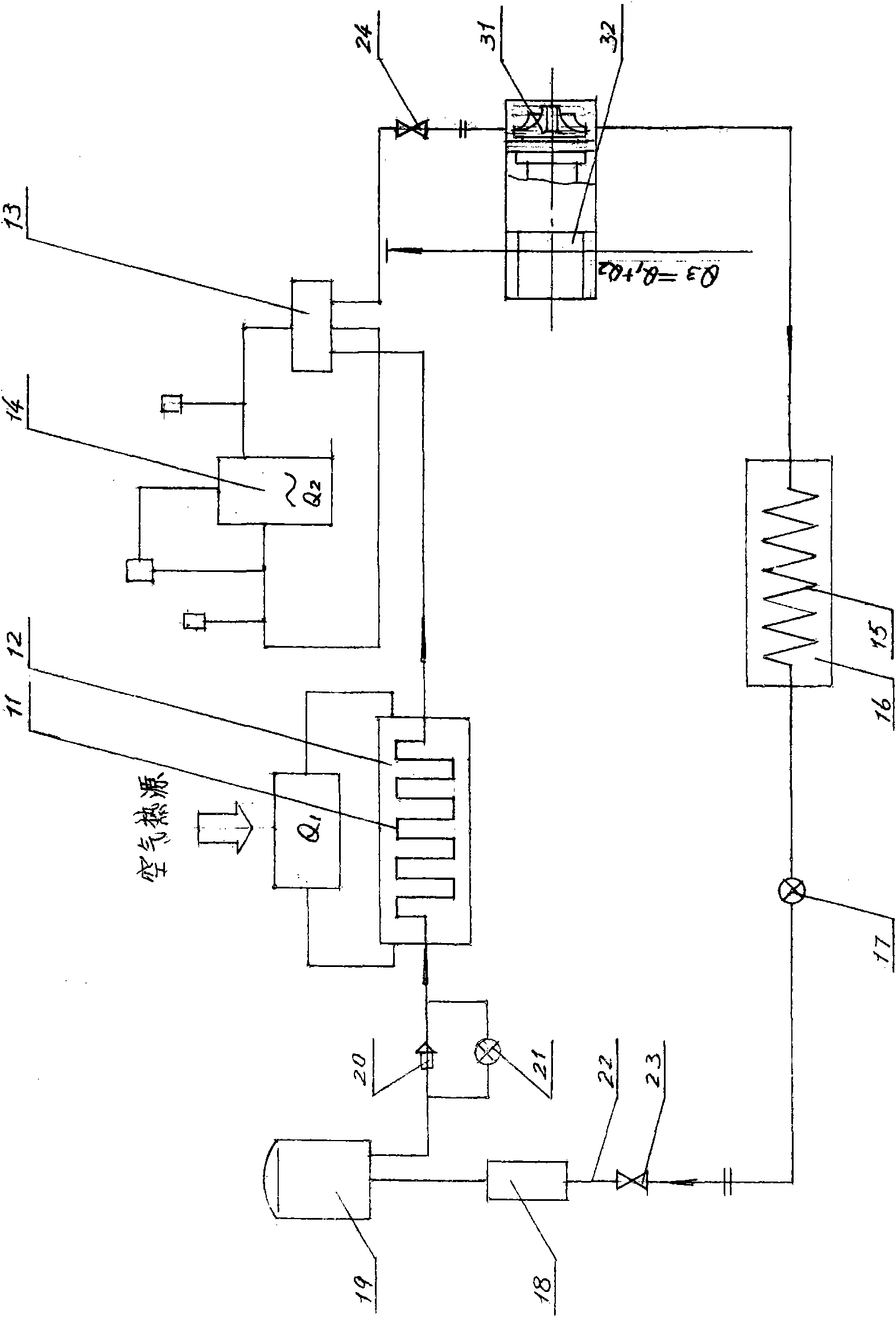

[0034] A single-cycle digital scroll thermodynamic power generation device as shown in Figure 1, which uses the heat of the air heat source, uses a low-boiling point working medium, performs work in a closed state and self-circulates, realizes the thermal conversion work to output mechanical energy or drive a generator Output electric power, including evaporator (11), air heat exchanger (12), four-way reversing valve (13), digital scroll compressor (14), low temperature turbine (31), generator (32) , Condenser (15), condensate tank (16), electronic expansion valve (17), engineering filter (18), accumulator (19), one-way valve (20), electronic expansion valve (21), pipeline Composed of low boiling point working fluid (22), bellows stop valve (23), (24), the above condenser (15) can also be replaced by a double-pipe heat exchanger, and the evaporator (11) is in the air heat exchanger ( In 12), the condenser (15) is in the condensate tank (16), between the evaporator (11) and the ...

Embodiment 2

[0038] A dual-cycle digital scroll thermodynamic power generation device as shown in Figure 2, which uses the heat of the air heat source, uses a low-boiling point working fluid, performs work in a closed state and self-circulates to achieve thermal transfer work output mechanical energy or drive generator output Electric power, which consists of three systems including the digital scroll heat pump system (10), the low-temperature turbine and its exhaust gas regenerative circulation system (30), and the double tube plate heat pipe device (50). The specific structure is as follows; The cyclonic heat pump system (10) includes an evaporator (11), an air heat exchanger (12), a four-way reversing valve (13), a digital scroll compressor (14), a heat exchanger (15), and a hot water exchange tank ( 16), electronic expansion valve (17), engineering filter (18), accumulator (19), one-way valve (20), electronic expansion valve (21), low boiling point working fluid in the pipeline (22), bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com