Method for directionally solidifying and purifying polycrystalline silicon under DC electric field

A technology of directional solidification and DC electric field, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of increasing difficulty, no purification effect of impurities, etc., and achieve the effect of low content of crystal impurities

Inactive Publication Date: 2010-08-25

上海太阳能电池研究与发展中心

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

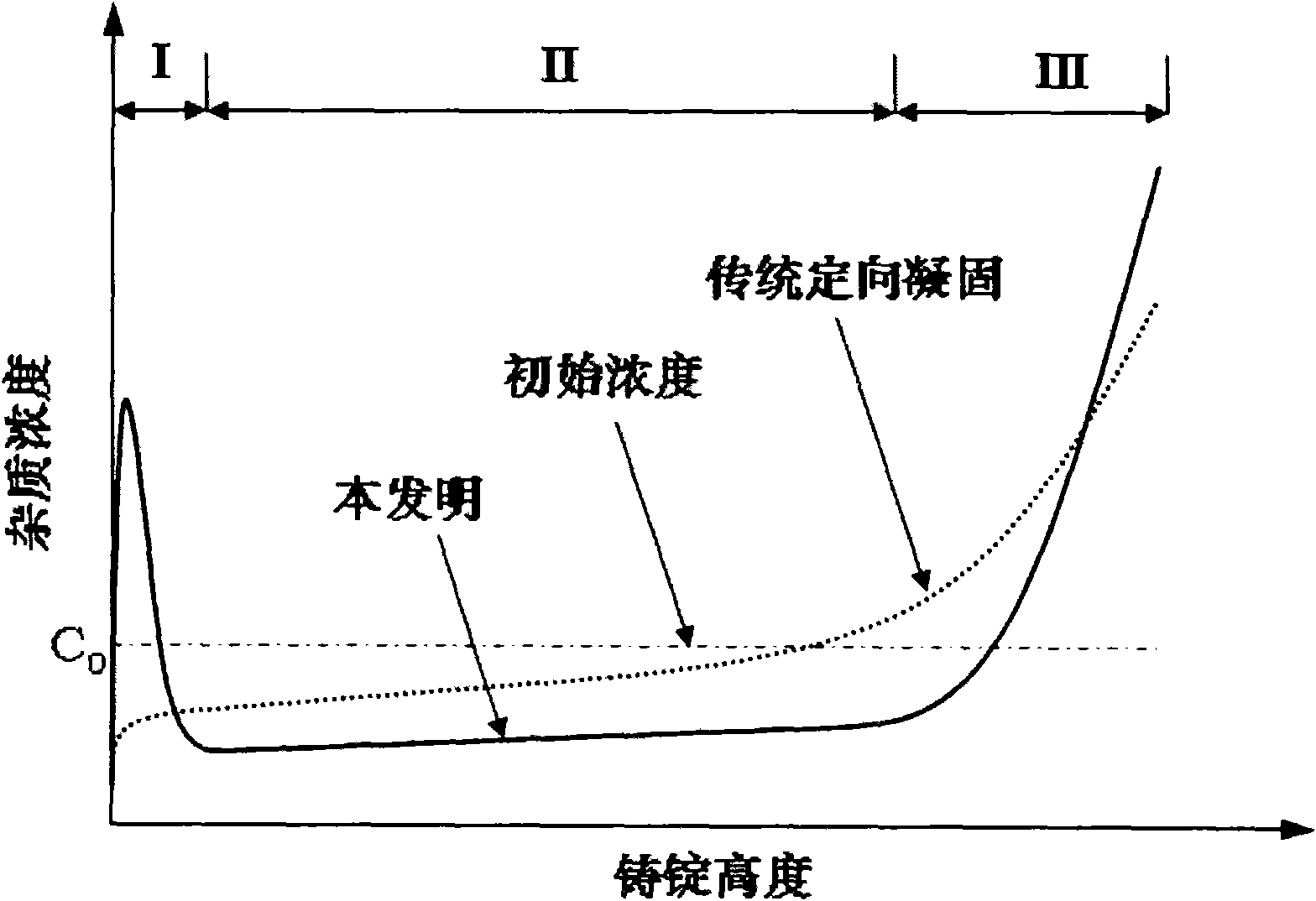

However, some elements, such as boron (B), phosphorus (P), etc., have an equilibrium segregation coefficient in silicon close to 1, and the usual directional solidification process has almost no purification effect on these impurities, so directional solidification requires raw materials to have a lower B , P content, which greatly increases the difficulty of the previous process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

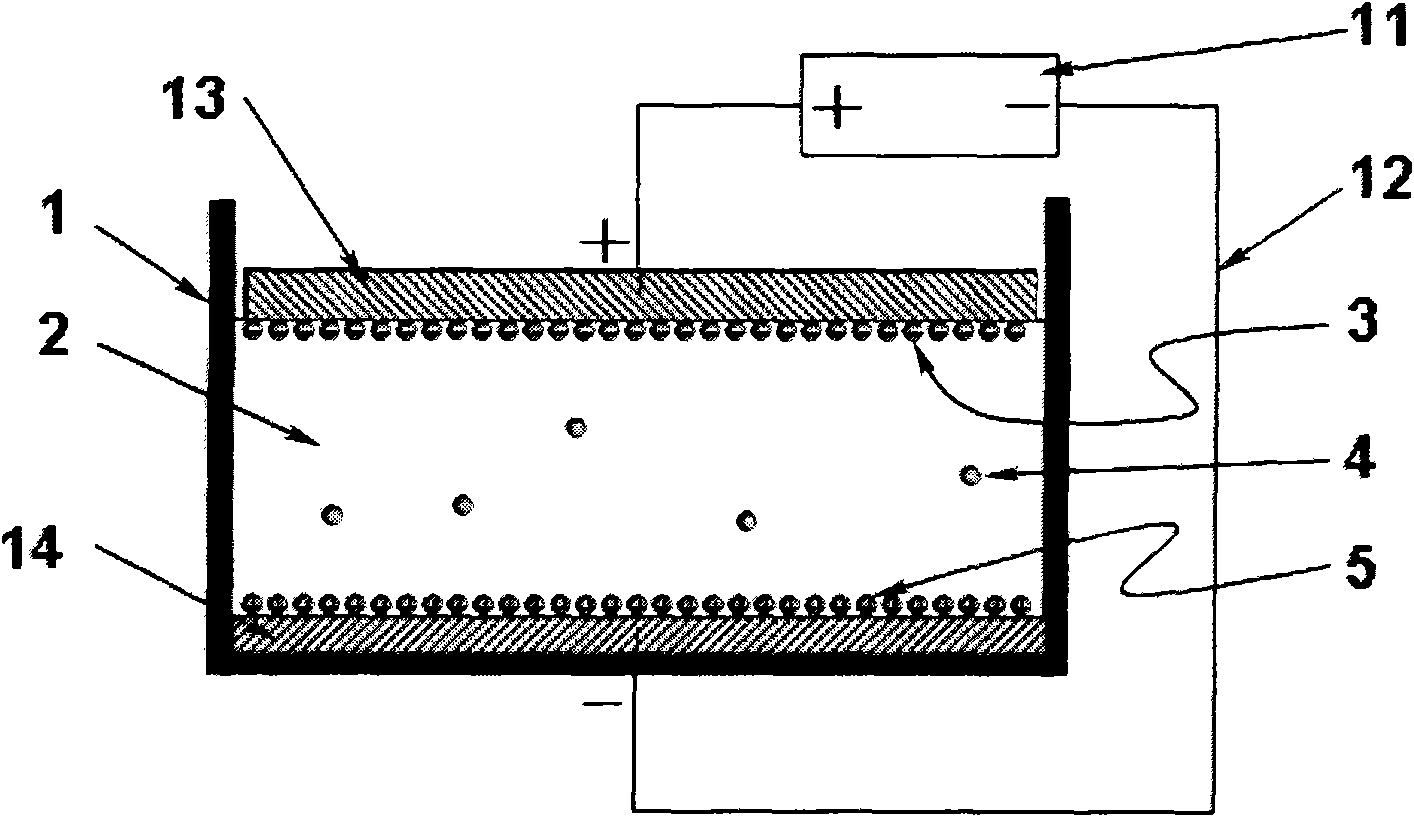

The invention discloses a method for directionally solidifying and purifying polycrystalline silicon under the action of a DC electric field. In the method, the DC electric field which is parallel to the crystal growth direction is applied to fused silicon solution in the growth process of the polycrystalline silicon directional solidification crystal, so that the impurities rapidly move to the electrode direction under the action of the electric field, namely the cation impurities move to the cathode direction, and the anion impurities move to the anode direction. Therefore, the impurity concentration in the crystal growth terminal liquid phase is effectively reduced and the crystal impurity content of subsequent growth is lowered, and polycrystalline silicon ingots of which the directional solidification purity is higher than that of the traditional method for directionally solidifying and purifying the polycrystalline silicon are obtained.

Description

Method for directional solidification and purification of polycrystalline silicon under direct current electric field Technical field The invention relates to the purification of polycrystalline silicon, in particular to a method for purifying polycrystalline silicon by directional solidification under the action of a direct current electric field. Background technique As the main raw material of crystalline silicon solar cells, polysilicon is in increasing demand with the rapid development of the photovoltaic industry. The main source of traditional solar-grade polycrystalline silicon is the remaining pot bottom material when producing electronic grade monocrystalline silicon, and waste materials such as monocrystalline silicon ingot cutting chips. At present, the (improved) Siemens method is the main method for producing high-purity polysilicon. Although the polysilicon obtained by this method has high purity, it has many shortcomings such as high energy consumption, high pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C30B29/06C30B28/06

Inventor 蒋君祥胡建锋熊斌徐璟玉戴宁褚君浩

Owner 上海太阳能电池研究与发展中心

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com