Method for making reducing gas special for indirect reduction of iron oxides

A technology of iron oxide and manufacturing method, applied in the direction of manufacturing combustible gas, granular/powdered fuel gasification, furnace, etc., can solve the problems of increasing carbon consumption, unfavorable energy saving, high processing cost, etc., to reduce consumption and cost The effect of low and high reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

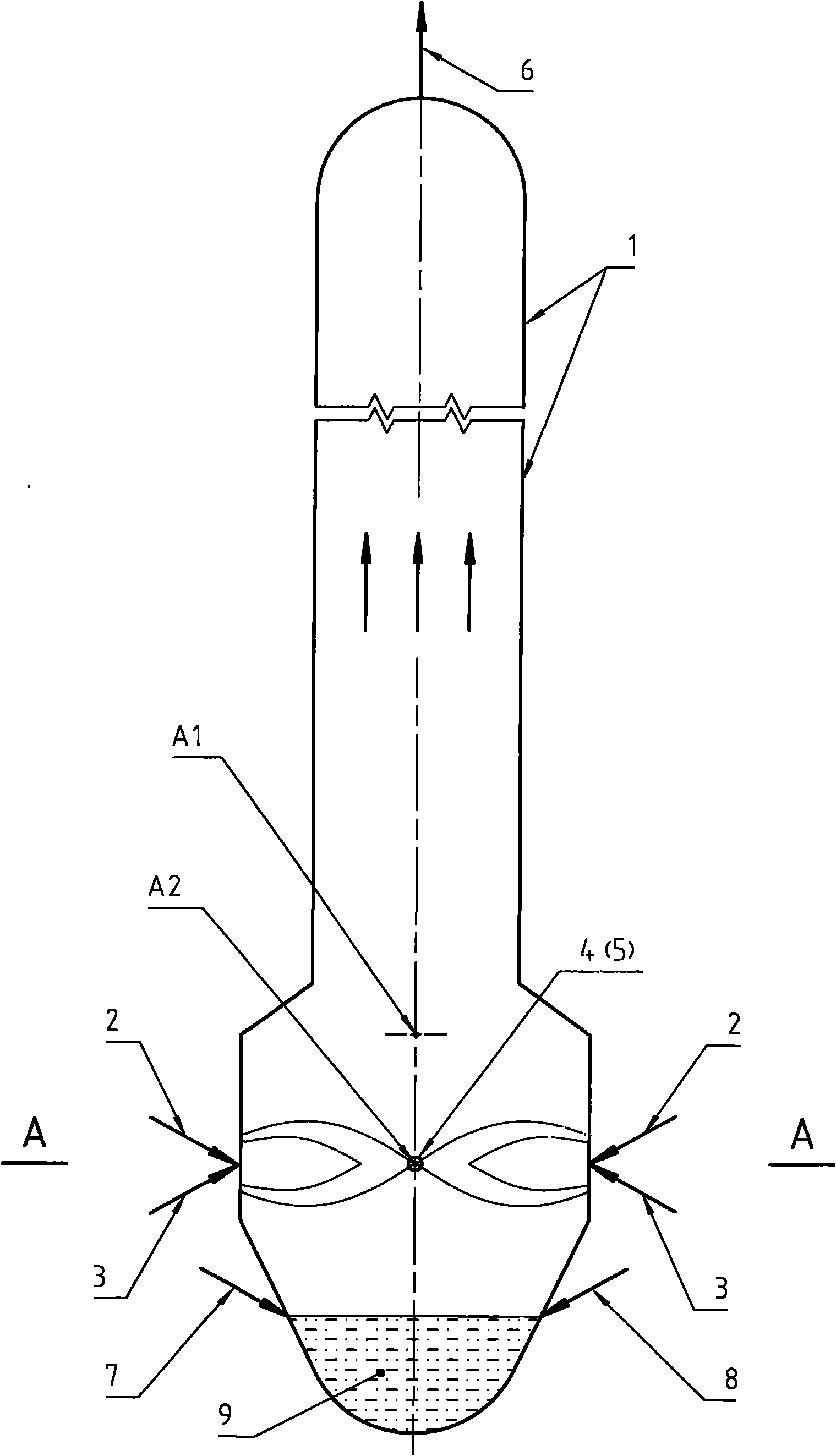

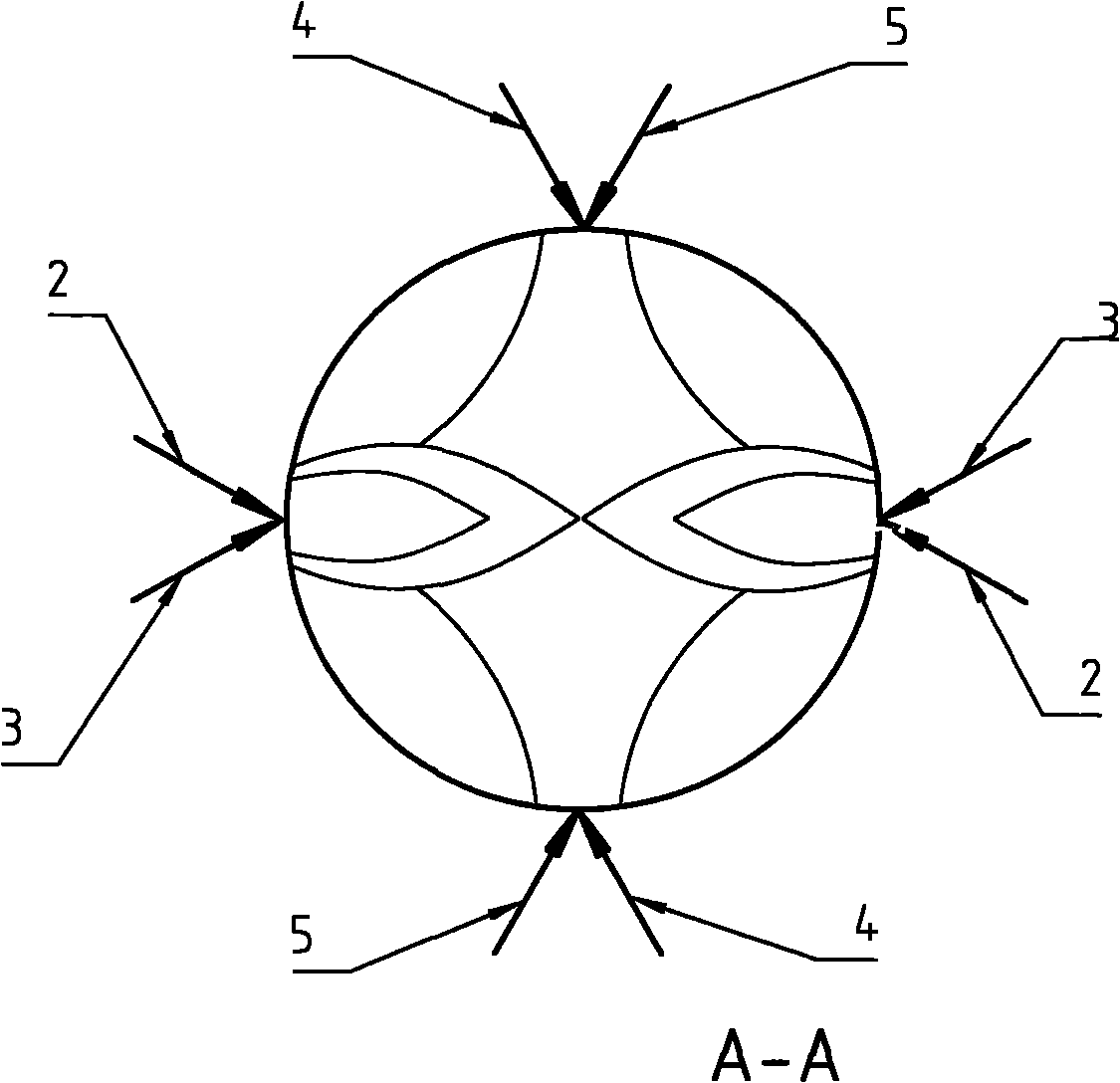

[0025] Example 1, such as figure 1 and figure 2 shown.

[0026] This embodiment is used to cooperate to illustrate the manufacturing method described in the present invention.

[0027] exist figure 1 Among them, 1 represents the gas generator. 2 represents the oxygen delivery channel. 3 represents the delivery passage of carbon (actually used is pulverized coal, the same below). 4 represents the delivery channel of coke oven gas. 5 represents the input channel of secondary carbon. 6 represents the delivery channel of the finished product reducing gas. 7 is a channel for injecting coke oven gas to the slag pool. 8 is a passage for injecting oxygen (also can be high-temperature hot air) to the slag pool. 9 is the liquid slag in the slag pond. exist figure 1 The positions A1 and A2 indicated in , indicate the optional positions of channels 4 and / or 5, and the specific determination of this position shall be carried out according to the combustion conditions in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com