Method for preparing sodium dodecyl benzene sulfonate doped titanium catalyzed electrode

A technology of sodium dodecylbenzenesulfonate and catalytic electrodes, which is applied in chemical instruments and methods, electrodes, electrolytic processes, etc., can solve the problems of low current efficiency, high energy consumption, and limitations, and achieve improved catalytic performance and increased The specific surface area and the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

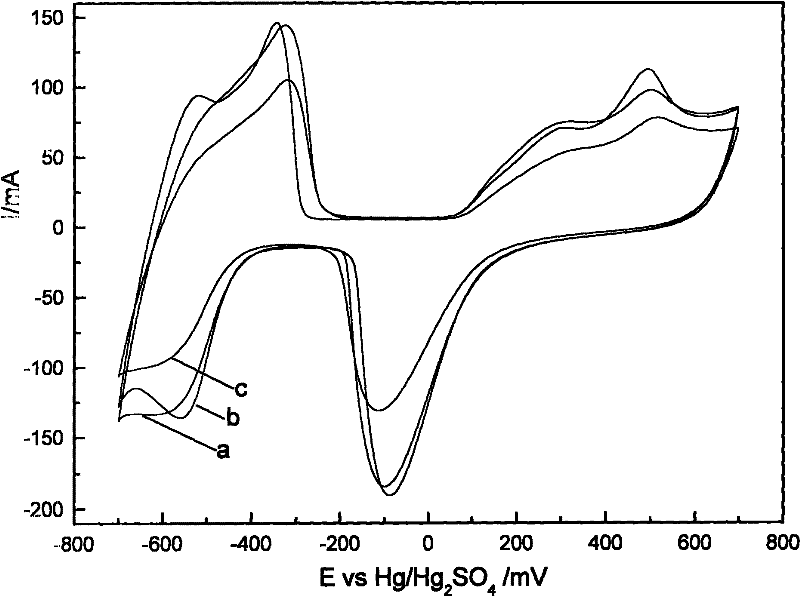

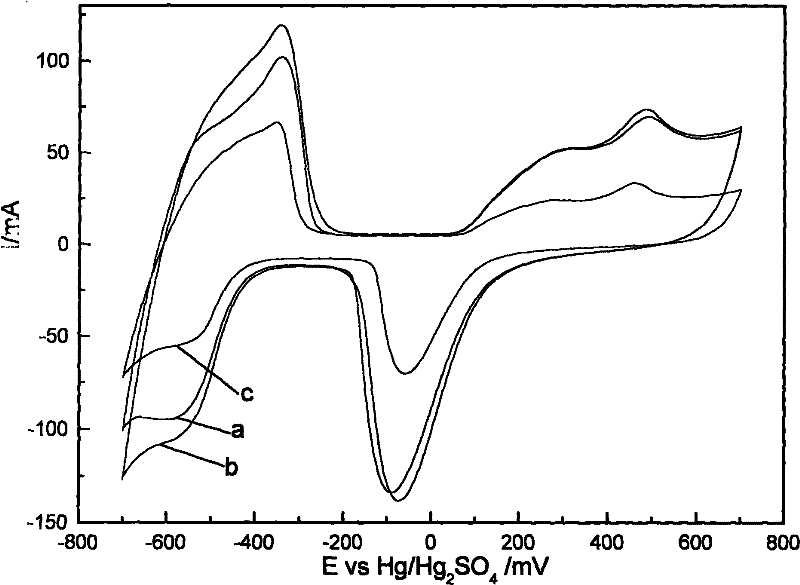

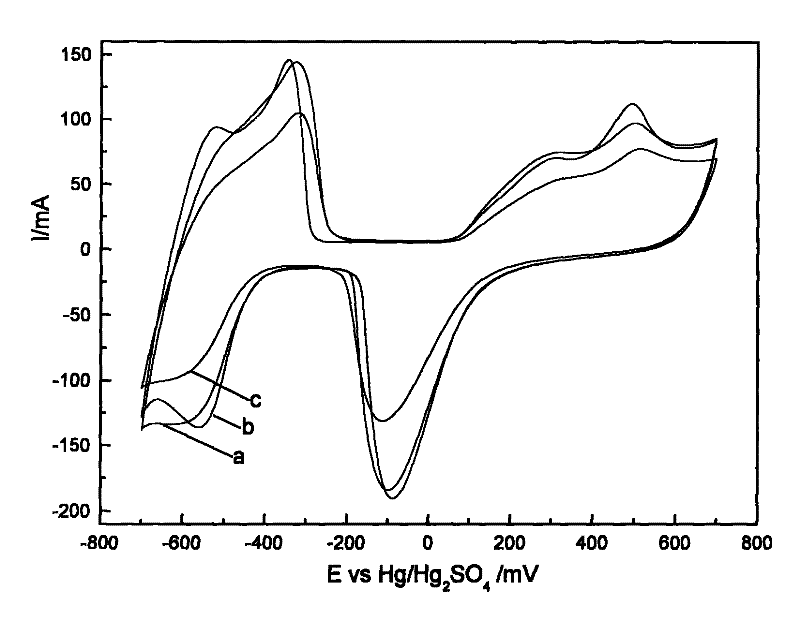

Image

Examples

Embodiment 1

[0020] 1) Weigh PdCl 2 Dissolve the powder in 3mol / L HCl solution, add deionized water to prepare 22.5mmol / L PdCl 2 solution;

[0021] 2) After immersing the titanium in 0.5mol / L sulfuric acid for 3 minutes to remove the surface matter, it was cleaned by ultrasonic vibration in acetone (degreasing) and double-distilled water for 15 minutes respectively, and dried for later use;

[0022] 3) After pyrrole and the sulfuric acid of 0.3mol / L are mixed by volume ratio 7: 1000, add sodium dodecylbenzenesulfonate to obtain mixed solution, the content of sodium dodecylbenzenesulfonate in the mixed solution is 0.00075g / mL;

[0023] 4) With the titanium treated in step 2) as the anode, the platinum sheet as the cathode, and the solution prepared in step 3) as the electrolyte, the PPy-SDBS / Ti electrode was prepared by electrodeposition, and the deposition current density was 0.625 mA / cm 2 , the deposition time is 5min;

[0024] 5) With the PPy-SDBS / Ti electrode as the cathode, the p...

Embodiment 2

[0027] 1) Weigh PdCl 2 Dissolve the powder in 3mol / L HCl solution, add deionized water to prepare 23mmol / L PdCl 2 solution;

[0028] 2) After immersing the titanium in 0.5mol / L sulfuric acid for 2 minutes to remove surface matter, it was cleaned by ultrasonic vibration in acetone (degreasing) and double distilled water for 12 minutes respectively, and dried for later use;

[0029] 3) After pyrrole and the sulfuric acid of 0.3mol / L are mixed by volume ratio 7: 1000, add sodium dodecylbenzenesulfonate to obtain mixed solution, the content of sodium dodecylbenzenesulfonate in the mixed solution is 0.001g / mL;

[0030] 4) With the titanium treated in step 2) as the anode, the platinum sheet as the cathode, and the solution prepared in step 3) as the electrolyte, the PPy-SDBS / Ti electrode was prepared by electrodeposition, and the deposition current density was 0.625 mA / cm 2 , the deposition time is 5min;

[0031] 5) With the PPy-SDBS / Ti electrode as the cathode, the platinum ...

Embodiment 3

[0034] 1) Weigh PdCl 2 Dissolve the powder in 3mol / L HCl solution, add deionized water to prepare 24.5mmol / L PdCl 2 solution;

[0035] 2) After immersing the titanium in 0.5mol / L sulfuric acid for 2 minutes to remove surface matter, it was cleaned by ultrasonic vibration in acetone (degreasing) and double distilled water for 10 minutes respectively, and dried for later use;

[0036] 3) After pyrrole and the sulfuric acid of 0.3mol / L are mixed by volume ratio 7: 1000, add sodium dodecylbenzenesulfonate to obtain mixed solution, the content of sodium dodecylbenzenesulfonate in the mixed solution is 0.0015g / mL;

[0037] 4) With the titanium treated in step 2) as the anode, the platinum sheet as the cathode, and the solution prepared in step 3) as the electrolyte, the PPy-SDBS / Ti electrode was prepared by electrodeposition, and the deposition current density was 0.625 mA / cm 2 , the deposition time is 5min;

[0038]5) With the PPy-SDBS / Ti electrode as the cathode, the platinu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com