High-voltage and high-power double-tuning electric deicing method for overhead transmission lines

An overhead transmission line, high-power technology, applied in overhead installation, electric heating devices, electrical components, etc., can solve the problems of low ice melting efficiency, difficult to popularize in a large area, and long ice melting time, so as to maximize the utilization rate of device capacity, The effect of wide application range and high ice melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

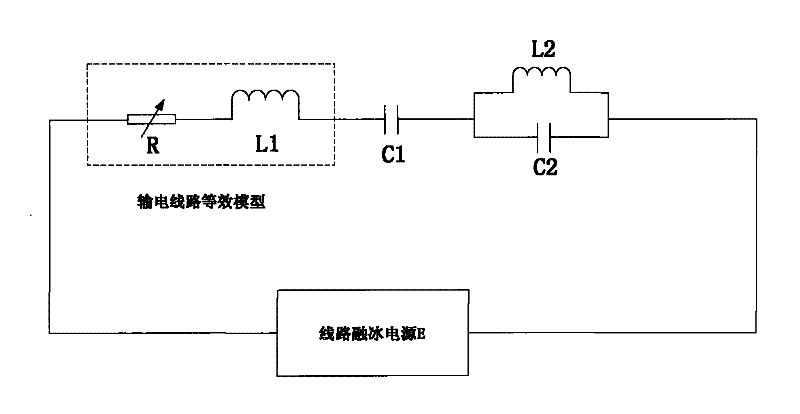

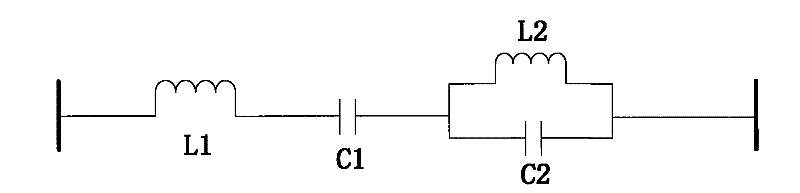

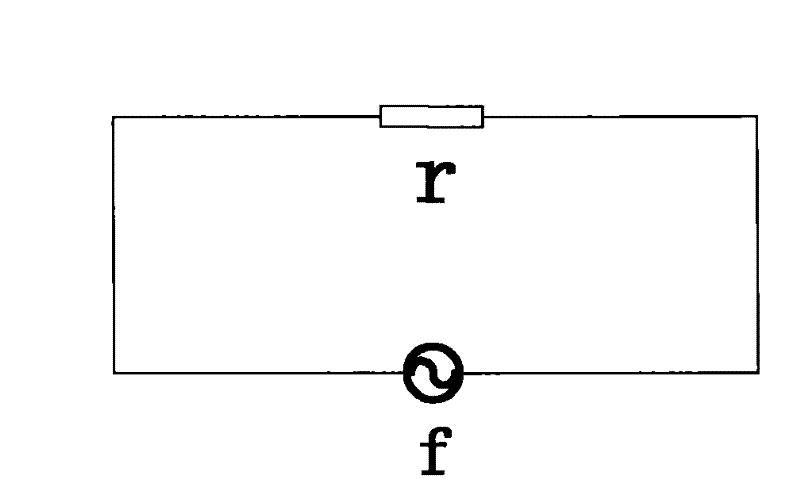

[0036] Option 1: Single-phase line deicing. Such as Figure 4 As shown, the neutral point of the de-icing power supply is grounded and the other end of the line is also grounded at the same time, and the resonant capacitor and parallel LC circuit are connected in series in the middle of the single-phase line, so that the de-icing power supply, the ice-coated line, and the ground form a loop. When deicing is powered on, the deicing power supply controls the output through the double resonance algorithm, so that the equivalent circuit of the deicing heating circuit that can be double tuned is as follows: image 3 As shown, high-efficiency electric heating transmission lines can quickly melt ice. This mode of operation is particularly suitable for the deicing of ground wires of transmission lines or catenaries of electrified railways.

[0037] Option 2: Three-phase lines are deiced at the same time. Considering that the line is a three-phase symmetrical load, one end of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com