Photosensitive resin composition and method for producing same

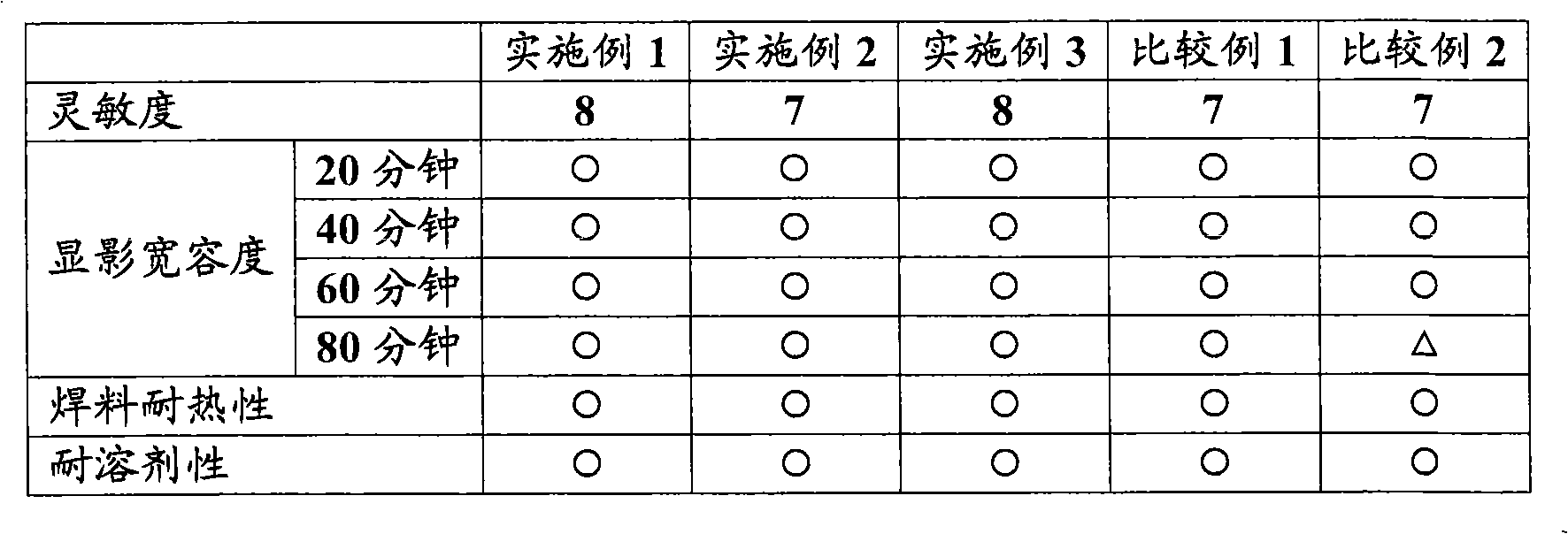

A technology of photosensitive resin and manufacturing method, which is applied in the field of photosensitive resin composition to achieve the effects of good thermal stability and good developing latitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to these examples.

Synthetic example 1

[0042] In the flask with stirrer, gas introduction pipe and reflux tube, add 192 parts by mass of ethyl carbitol acetate, dissolve 206 parts by mass (1 equivalent) of cresol novolak type epoxy resin (dongdu) therein Epoto-to (registered trademark) YDCN704 manufactured by Kasei Co., Ltd., epoxy equivalent 206). Further add 72 parts by mass (1.0 mole) of acrylic acid, 0.23 parts by mass of hydroquinone, 0.4 parts by mass of triphenylphosphine and 2 parts by mass of zirconium naphthenate (6% metal content), and blow into The reaction was continued at 130° C. for 10 hours while air was released, and a reactant (epoxy acrylate) having an acid value of 0.5 mgKOH / g was obtained. 76.0 parts by mass (0.5 mol) of tetrahydrophthalic anhydride was added there, and it was further reacted at 120° C. for 2 hours to obtain a reactant having a solid content acid value of 79.3 mgKOH / g. Ethyl carbitol acetate was added thereto so that the non-volatile matter would be 60%, and photosensitive res...

Synthetic example 2

[0044] Except using 2 parts by mass of zirconium octoate (12% of metal content) instead of 2 parts by mass of chromium naphthenate (6% of metal content), the same operation as Synthesis Example 1 was carried out to obtain a solid content acid value of 79.3 mgKOH / g reactants. Ethyl carbitol acetate was added thereto so that the non-volatile matter would be 60%, and photosensitive resin B was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com