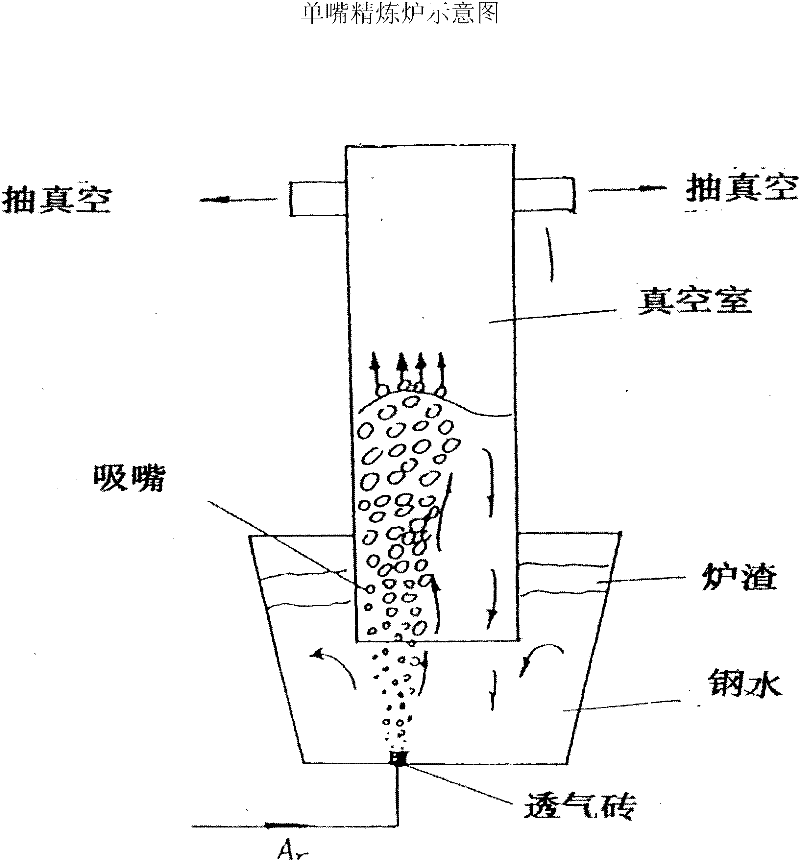

Method for smelting ultra-low hydrogen steel by using single-nozzle refining furnace

A single-mouth refining furnace, ultra-low hydrogen technology, applied in the smelting field of ultra-low hydrogen steel, can solve the problems of low consumption of refractory material of dipping pipe, short service life of refractory material of dipping pipe, serious nodules in vacuum chamber, etc., and achieve smelting time The effect of short, short processing time and less nodules in the vacuum chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Under the initial conditions of controlling the thickness of tapping slag = 30mm, the temperature of molten steel arriving at the station at 1570°C, and the hydrogen content at the station at H = 0.0008%, the following steps are carried out:

[0021] Step 1: Deslagging the molten steel by blowing argon or nitrogen at the bottom, the flow rate of argon or nitrogen is 5NL / min / ton of steel, so that the exposed area of molten steel reaches 50%;

[0022] Step 2: Then insert the dipping tube of the single-nozzle furnace into the molten steel in step 1. The depth of the dipping tube of the single-nozzle furnace inserted into the molten steel is 400mm.

[0023] Step 3: Vacuumize for 3 minutes to reach a vacuum degree of 78Pa. During the vacuuming process, argon blowing is carried out at the bottom of the ladle at the same time. The flow rate of argon blowing is 3NL / min / ton of steel. Argon time is less than or equal to 18min.

Embodiment 2

[0025] Under the initial conditions of controlling the thickness of tapping slag = 50mm, the temperature of molten steel arriving at the station at 1615°C, and the hydrogen content at the station at H = 0.0004%, the following steps are carried out:

[0026] Step 1: Deslagging the molten steel by blowing argon or nitrogen at the bottom, the flow rate of argon or nitrogen is 4NL / min / ton of steel, so that the exposed area of molten steel reaches 40%;

[0027] Step 2: Then insert the dipping tube of the single-nozzle furnace into the molten steel in step 1. The depth of the dipping tube of the single-nozzle furnace inserted into the molten steel is 350mm.

[0028] Step 3: Vacuumize for 2 minutes to reach a vacuum degree of 68Pa. During the vacuuming process, argon blowing is carried out at the bottom of the ladle at the same time. The flow rate of argon blowing is 2NL / min / ton of steel. Argon time was 16 min.

Embodiment 3

[0030] Under the initial conditions of controlling the thickness of tapping slag = 50mm, the temperature of molten steel arriving at the station at 1615°C, and the hydrogen content at the station at H = 0.0007%, the following steps are carried out:

[0031] Step 1: Deslagging the molten steel by bottom blowing argon or nitrogen, the flow rate of argon or nitrogen is 7NL / min / ton of steel, so that the exposed area of molten steel reaches 60%

[0032] Step 2: Then insert the dipping tube of the single-nozzle furnace into the molten steel in step 1. The depth of the dipping tube of the single-nozzle furnace inserted into the molten steel is 350mm.

[0033] Step 3: Vacuumize for 4 minutes to reach a vacuum degree of 68Pa. During the vacuuming process, argon blowing is carried out at the bottom of the ladle at the same time. The flow rate of argon blowing is 3.7NL / min / ton of steel, and the flow rate of argon gas remains unchanged until the end of molten steel treatment. The total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com