Hybrid power control system for vehicle

A hybrid power and control system technology, applied in hybrid vehicles, power units, vehicle components, etc., can solve the problems of low total efficiency, low total efficiency, vehicle usage, etc., so as to improve energy utilization efficiency and improve vehicle power. , the effect of improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

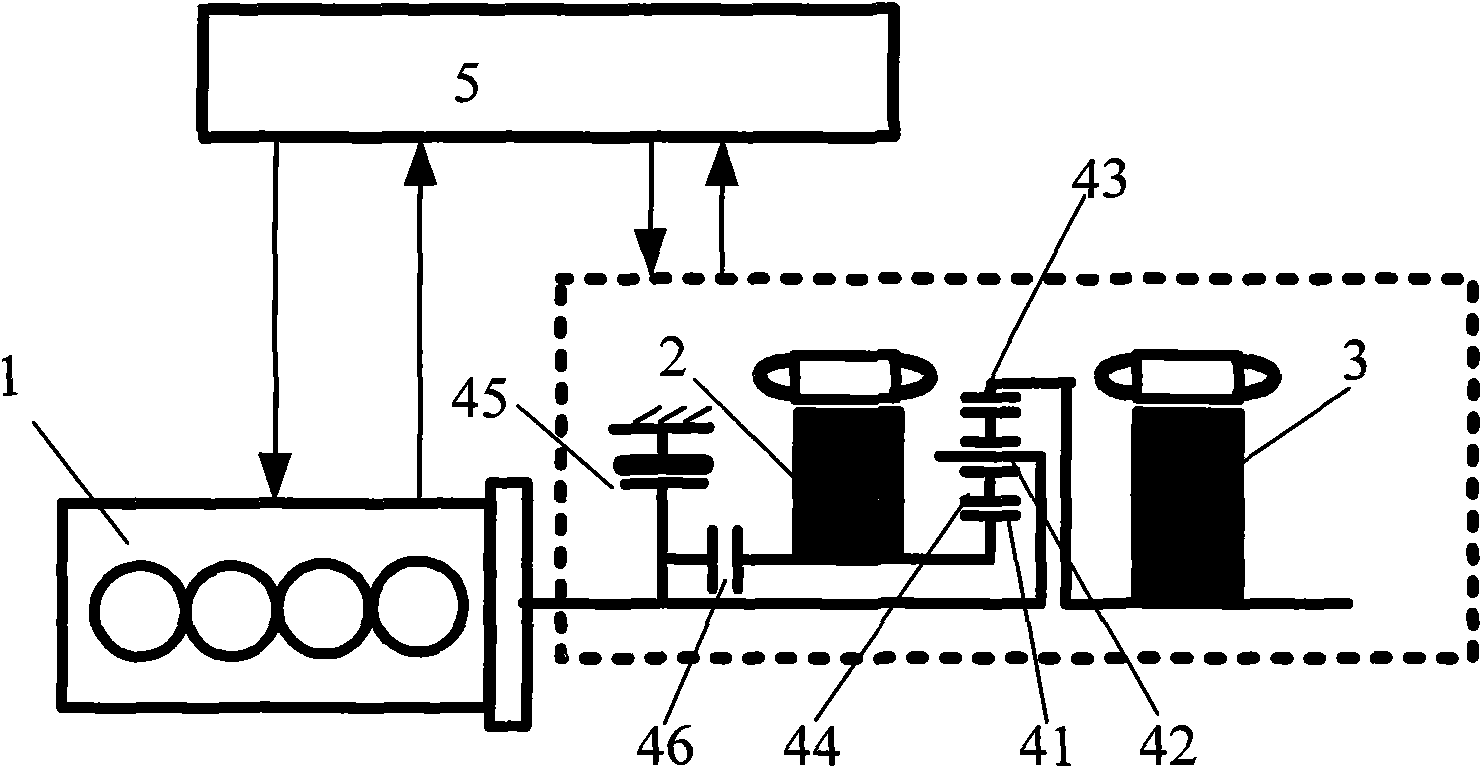

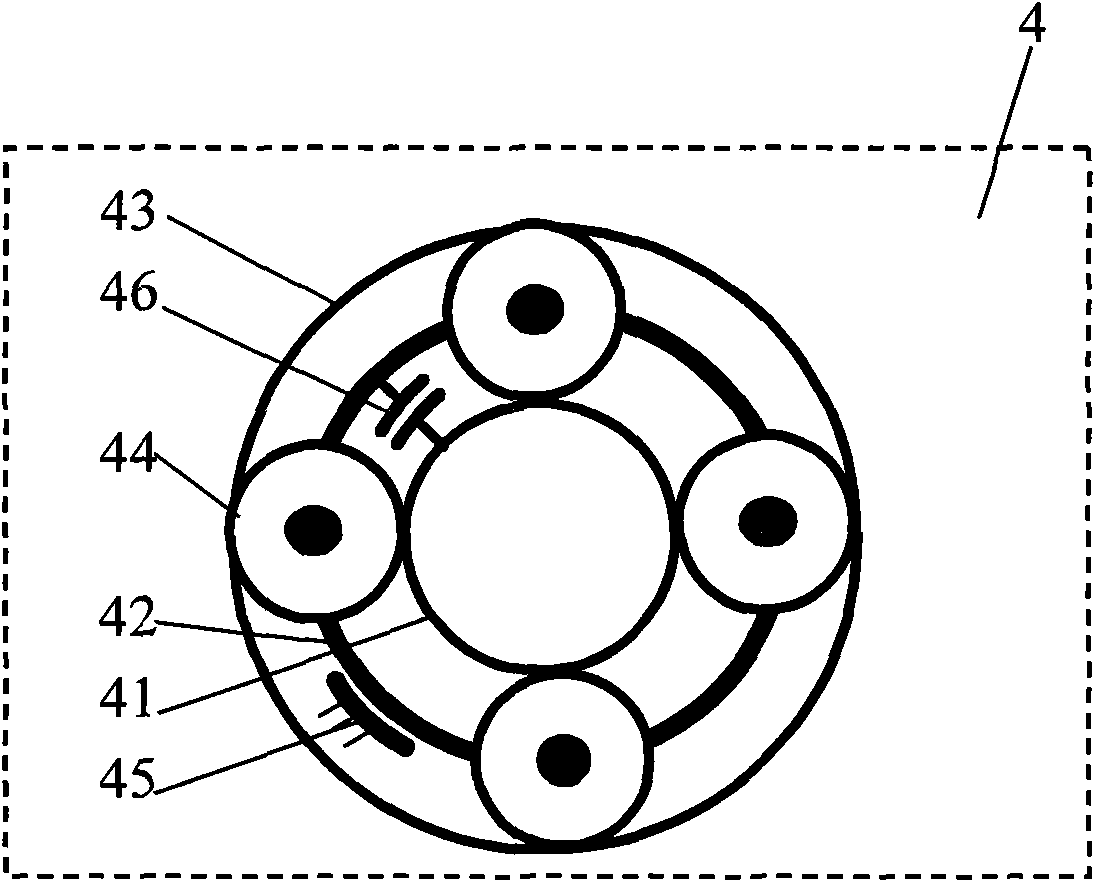

[0029] Such as Picture 1-1 and Figure 1-2 Shown, the first kind of technical scheme as realizing the basic idea of the vehicle hybrid control system of the present invention is: comprising engine 1, first generator / motor 2, second generator / motor 3, power coupling and distributing device 4, Controller 5. The power coupling and distribution device 4 includes a sun gear 41 , a planetary carrier 42 , a ring gear 43 , a planetary gear 44 , a brake 45 and a clutch 46 . Wherein, the brake 45 is used for braking the planet carrier 42, the brake 45 includes a fixed part and a rotating part, the rotating part of the brake 45 is connected to the planet carrier 42, the output shaft of the engine 1 is connected to the The planet carrier 42 is connected; the clutch 46 is used to control the relative rotation between the sun gear 41 and the planet carrier 42, one end of the clutch 46 is connected to the planet carrier 42, and the other end of the clutch 46 The sun gear 41 is connected...

Embodiment approach 2

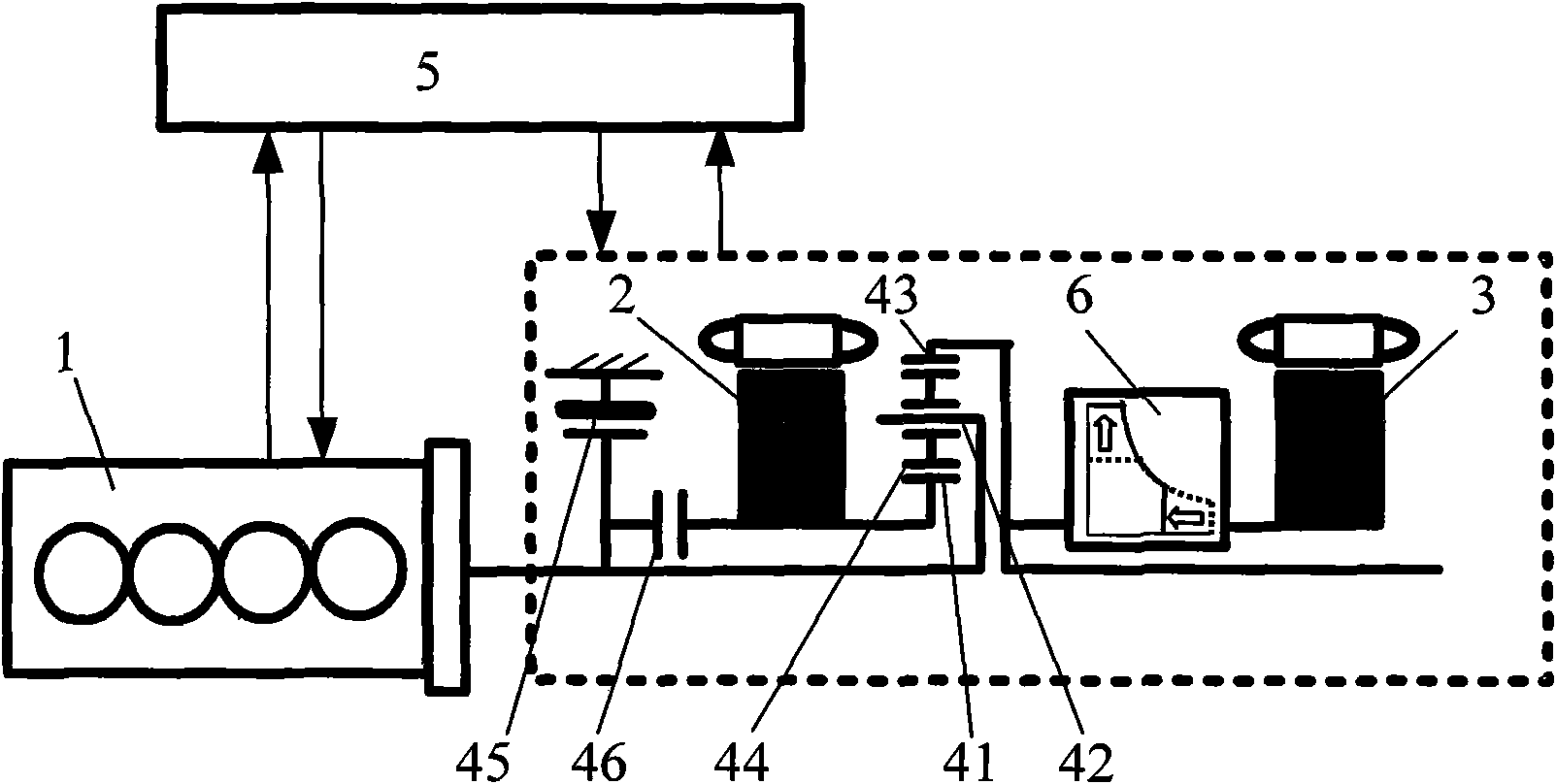

[0039] Such as figure 2 as shown, figure 2 The power coupling shown in is the same as the end view of distribution device 4 Figure 1-2 As shown, the second technical solution as the basic idea of the vehicle hybrid control system of the present invention is: including the output shaft of the engine 1, the first generator / motor 2, the second generator / motor 3, power coupling and distribution Device 4, controller 5, deceleration mechanism 6. The power coupling and distribution device 4 includes a sun gear 41 , a planetary carrier 42 , a ring gear 43 , a planetary gear 44 , a brake 45 and a clutch 46 . Wherein, the brake 45 is used for braking the planet carrier 42, the brake 45 includes a fixed part and a rotating part, the rotating part of the brake 45 is connected to the planet carrier 42, and the output shaft of the engine 1 is connected to the The planet carrier 42 is connected; the clutch 46 is used to control the relative rotation between the sun gear 41 and the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com