Fluidized bed reactor

A fluidized bed reactor and reactor technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased external circulation compressor power, reduced reactor production capacity, and small catalyst loading coefficient, etc. Achieve the effects of bed temperature balance, bed pressure reduction, and a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

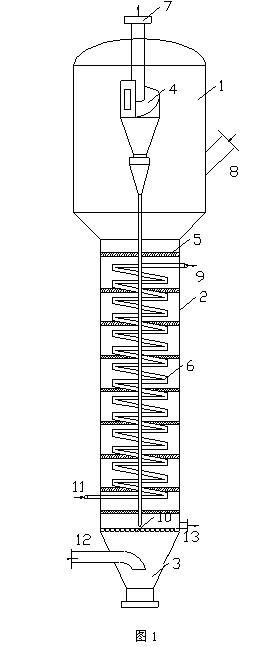

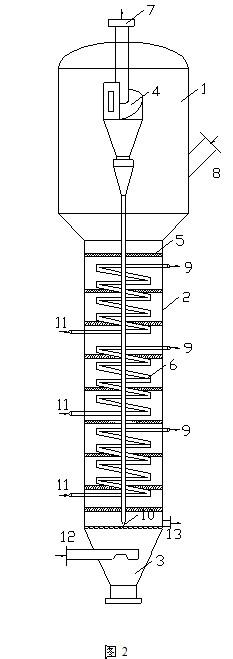

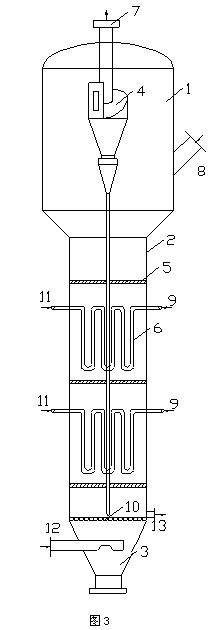

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings. The following are only preferred embodiments of the present invention, and the scope of the present invention cannot be limited thereto. That is, all equivalent changes and modifications made according to the scope of the patent application of the present invention should still fall within the scope covered by the patent of the present invention.

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] Such as figure 1As shown, the present invention comprises: the expansion tube 1 at the upper end of the reactor, the straight tube 2 in the middle of the reactor, the cone bottom 3 at the bottom of the reactor, the cyclone separator 4, the internal components 5, the heat exchange device 6, the product gas outlet 7 at the top of the shell , Catalyst filling port 8 on the expansion tube, heat transfer medium outlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com