Natural combustion waste oil incinerator

An incineration device and natural combustion technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problem of no effective means for glycerin treatment, achieve complete combustion reliability, low price, and save the troublesome effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

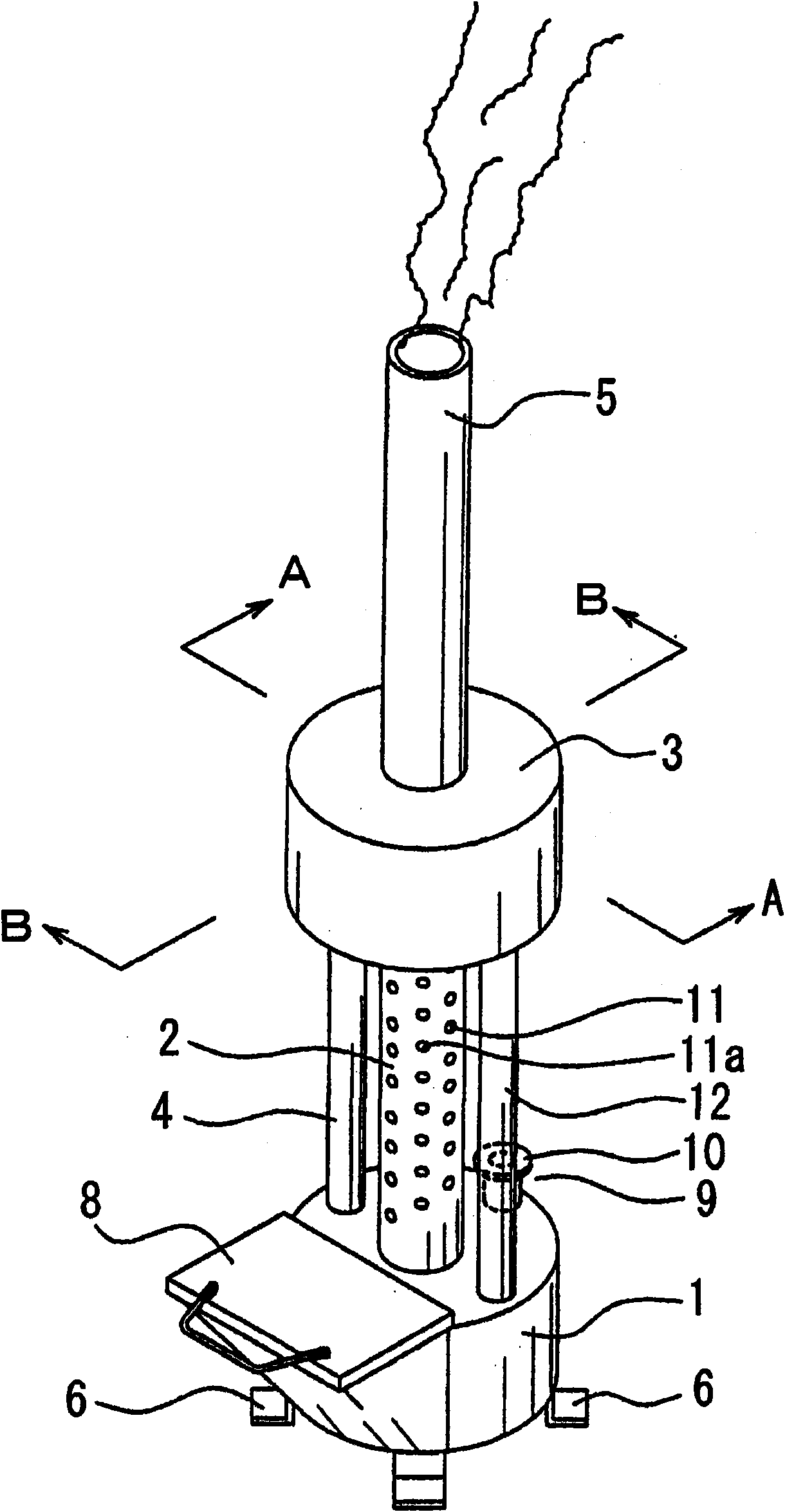

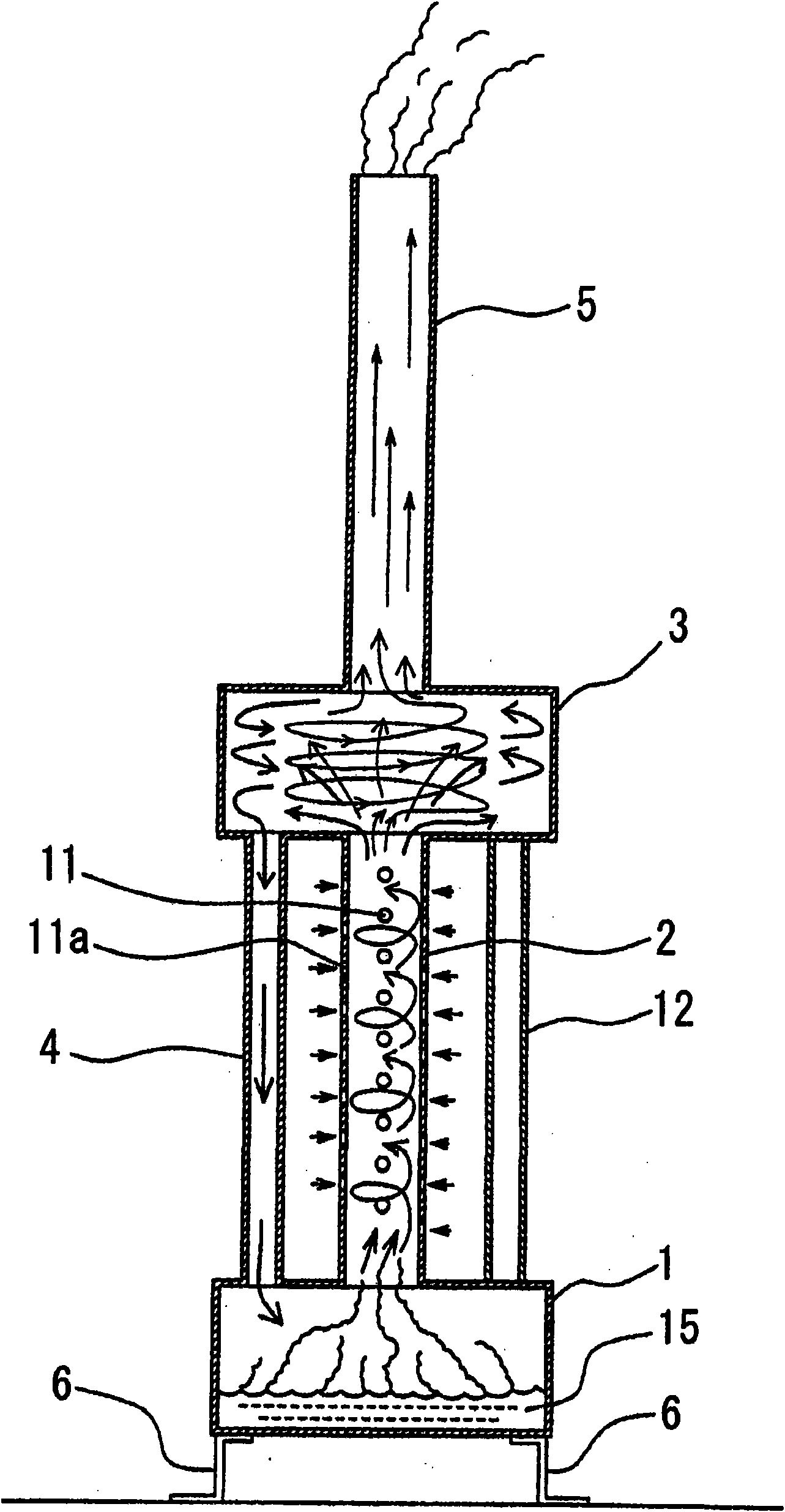

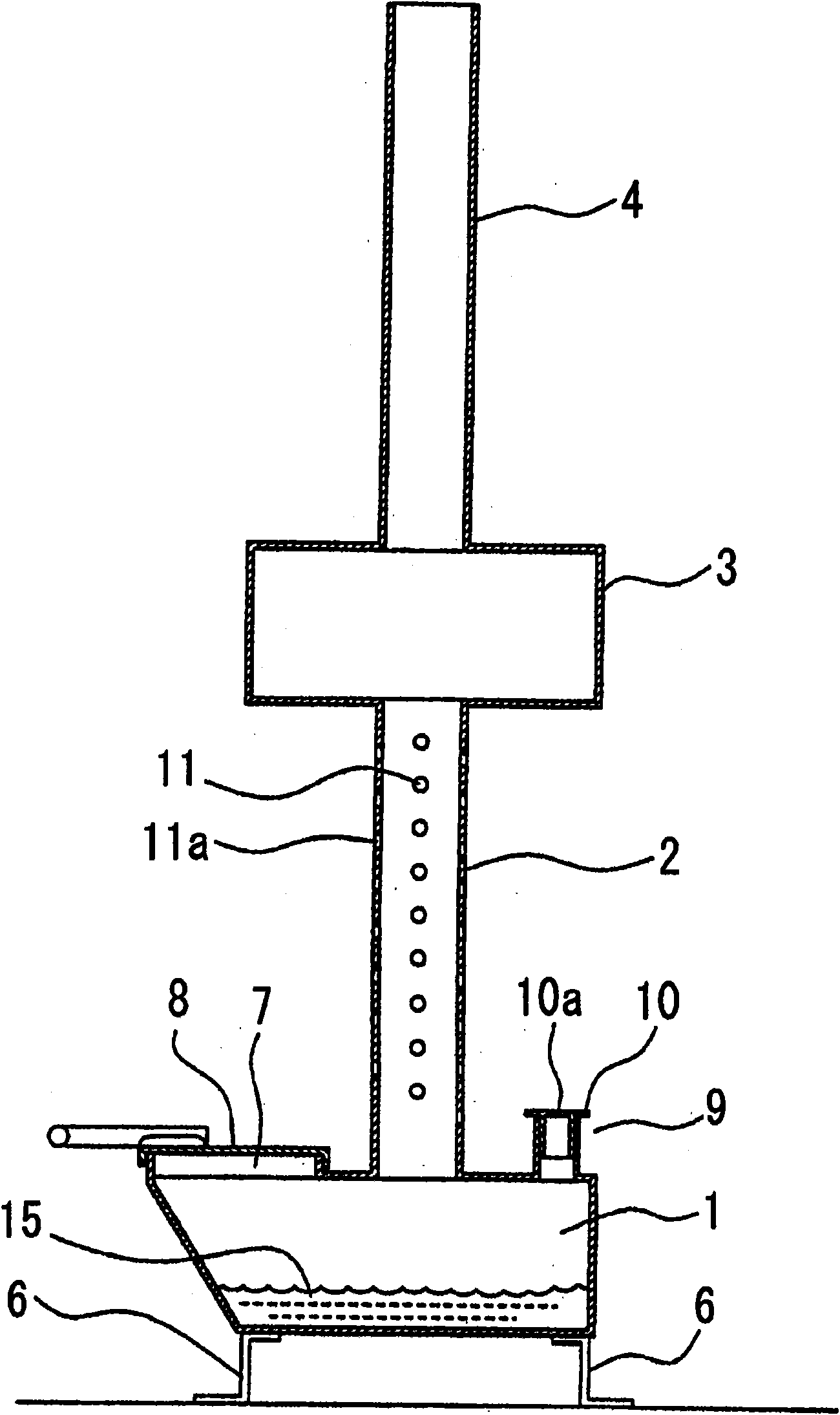

[0025] Preferred modes for implementing the present invention will be described with reference to the drawings. Figure 1 to Figure 4 Showing the first embodiment of the present invention, figure 1 is its stereogram, figure 2 is along figure 1 A cross-sectional view of line A-A in, image 3 is along figure 1 The cross-sectional view of the B-B line in, Figure 4 It is a perspective view which shows the modification.

[0026] In the first embodiment of the natural combustion type waste oil incineration device of the present invention, the device includes: a combustion chamber 1; a combustion cylinder 2 standing up from the central opening on the upper surface of the combustion chamber 1; The return chamber 3 ; the return pipe 4 connecting the return chamber 3 and the combustion chamber 1 ; and the exhaust tube 5 arranged in the return chamber 3 .

[0027] The combustion chamber 1 is a container having a plurality of legs 6 , has an inlet 7 on the upper surface, and an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com