Bonding substrate manufacturing apparatus and bonding substrate manufacturing method

A technology for manufacturing devices and substrates, which is applied in the field of bonded substrate manufacturing devices, can solve problems such as the decline in yield, and achieve the effects of ensuring cleanliness, improving production efficiency, and improving positional alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0065] (First embodiment) (bonded substrate manufacturing apparatus)

[0066] according to Figure 1 to Figure 11 The bonded substrate manufacturing apparatus in the first embodiment of the present invention will be described.

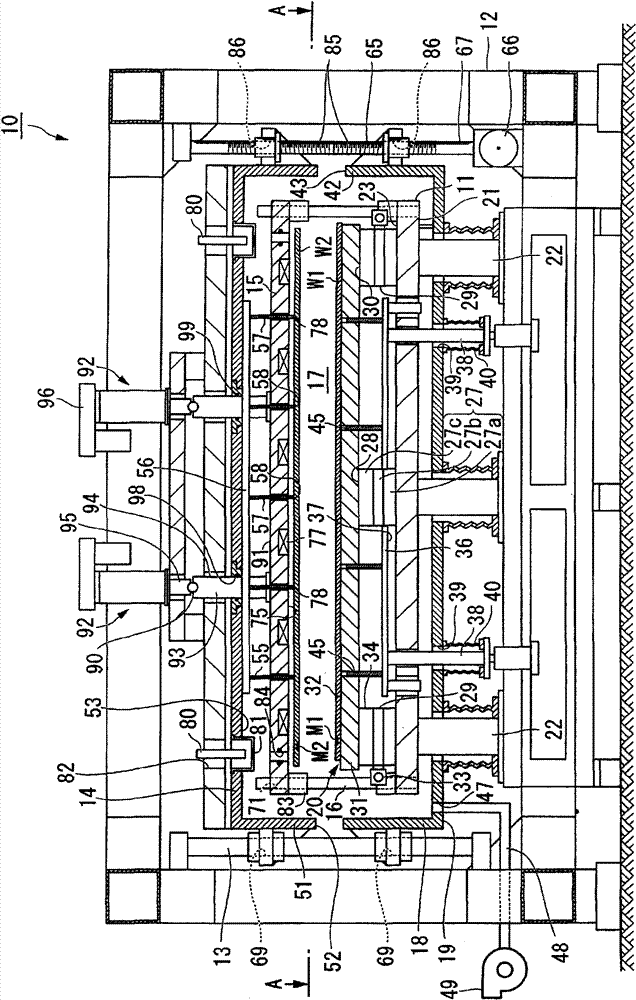

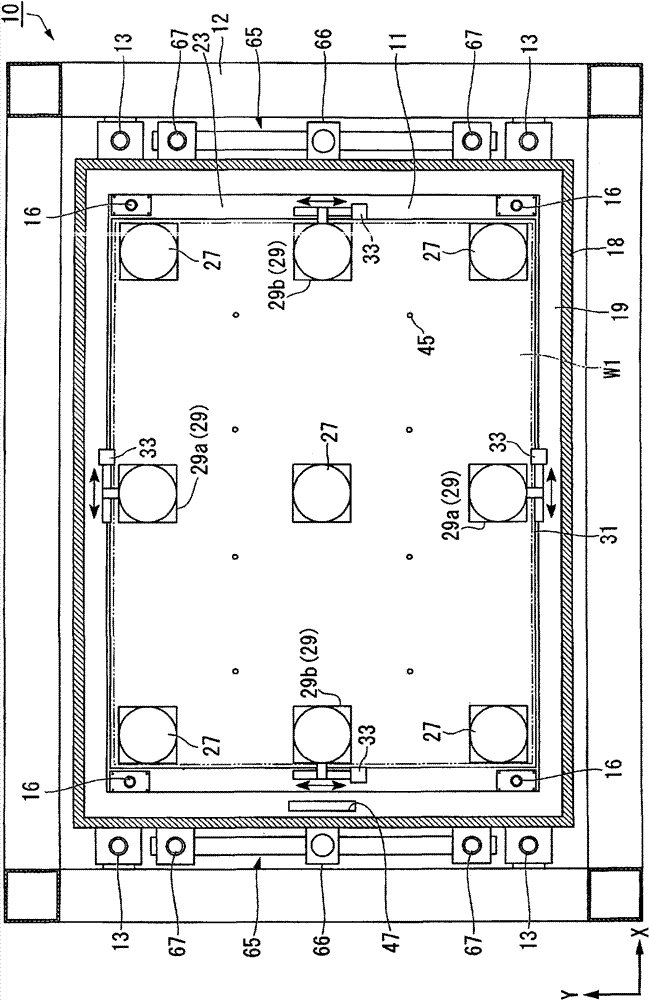

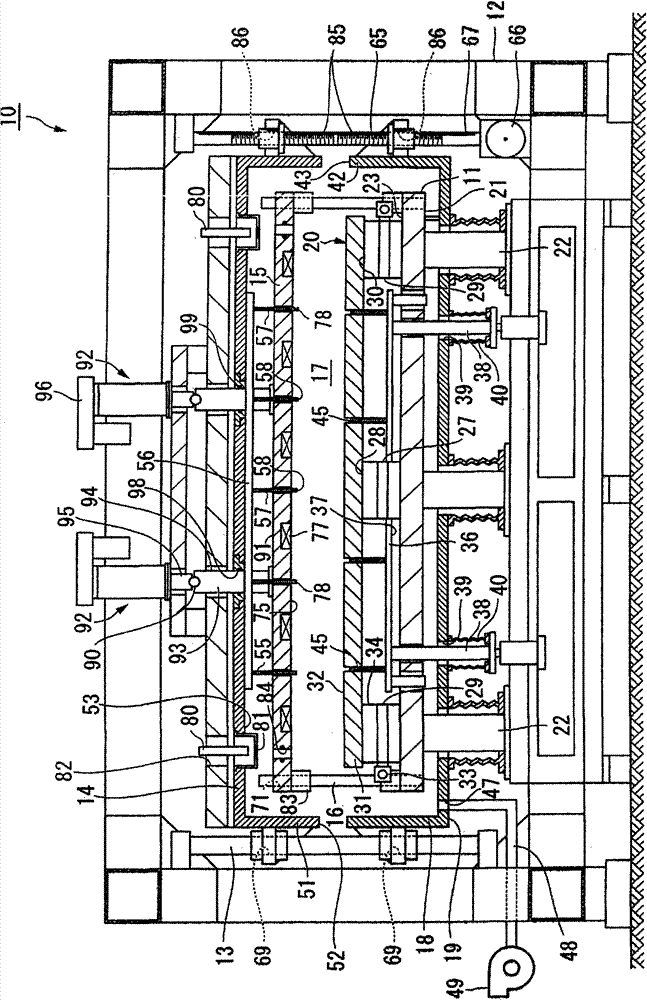

[0067] figure 1 It is a schematic front view of the bonded substrate manufacturing equipment, figure 2 is along figure 1 Sectional view of line A-A. Such as figure 1 , figure 2 As shown, the bonded substrate manufacturing apparatus 10 is provided with: a general-purpose stand 12 for supporting the whole of the device, a base portion 11 disposed on the general-purpose stand 12, a second support bar 13 arranged on the general-purpose stand 12, and a the upper chamber member 14 and the lower chamber member 18 moving up and down, the first support rod 16 erected from the base portion 11, and the upper chamber member 14 and the lower chamber member 18 independently and capable of moving up and down along the first support rod 16, and The upper pres...

no. 2 approach

[0126] Next, according to Figure 12 to Figure 14 A bonded substrate manufacturing apparatus according to a second embodiment of the present invention will be described. In addition, since the present embodiment differs from the first embodiment only in the manner in which the lower substrate W1 is placed, and other structures are substantially the same, the same reference numerals are assigned to the same parts and detailed descriptions are omitted.

[0127] Figure 12 It is a schematic front view of the bonded substrate manufacturing equipment, Figure 13 is along Figure 12 Sectional view of the B-B line. Such as Figure 12 , Figure 13 As shown, the upper surface 123 of the base portion 111 is formed in a rectangular shape in a plan view, and the lower substrate W1 can be placed thereon. A drive table 125 is provided at approximately the center of the upper surface 123 in a plan view, and the drive table 125 can move the lower substrate W1 in the vertical direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com