Whey protein hydrolysate

一种乳清蛋白水解、乳清蛋白的技术,应用在生成乳清蛋白水解物领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Whey protein concentrate (Lacprodan 80) from Arla Foods, Denmark (Lacprodan 80) (containing approximately 80% protein in total dry matter) was hydrolyzed using 5 different proteolytic enzymes. Enzymes and dosages are:

[0058] Trypsin-like protease from Fusarium oxysporum at a dose of 500 mg enzyme protein / kg raw material.

[0059] PTN 6.0 (Novozymes A / S) at a dosage of 0.5% of the starting material.

[0060] Alcalase 2.4L (Novozymes A / S) at a dose of 0.2% of the starting material.

[0061] Neutrase 0.8L (Novozymes A / S) at a dose of 1% of the starting material.

[0062] Protamex 1.5MG (Novozymes A / S) at a dose of 0.5% of raw material.

[0063] The whey protein concentrate was mixed with water (1:9) before adding the enzymes.

[0064] Hydrolysis took place at 50°C in a beaker fitted with a base (0.1 N NaOH) dosing system to keep the pH constant at pH 7.5 until the degree of hydrolysis (DH) = 4%.

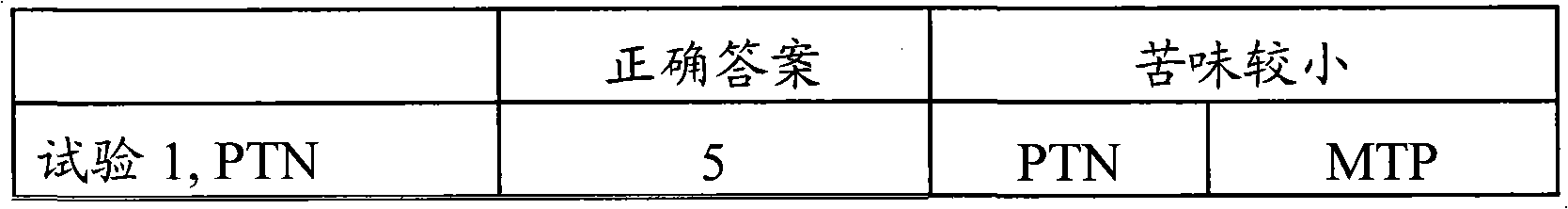

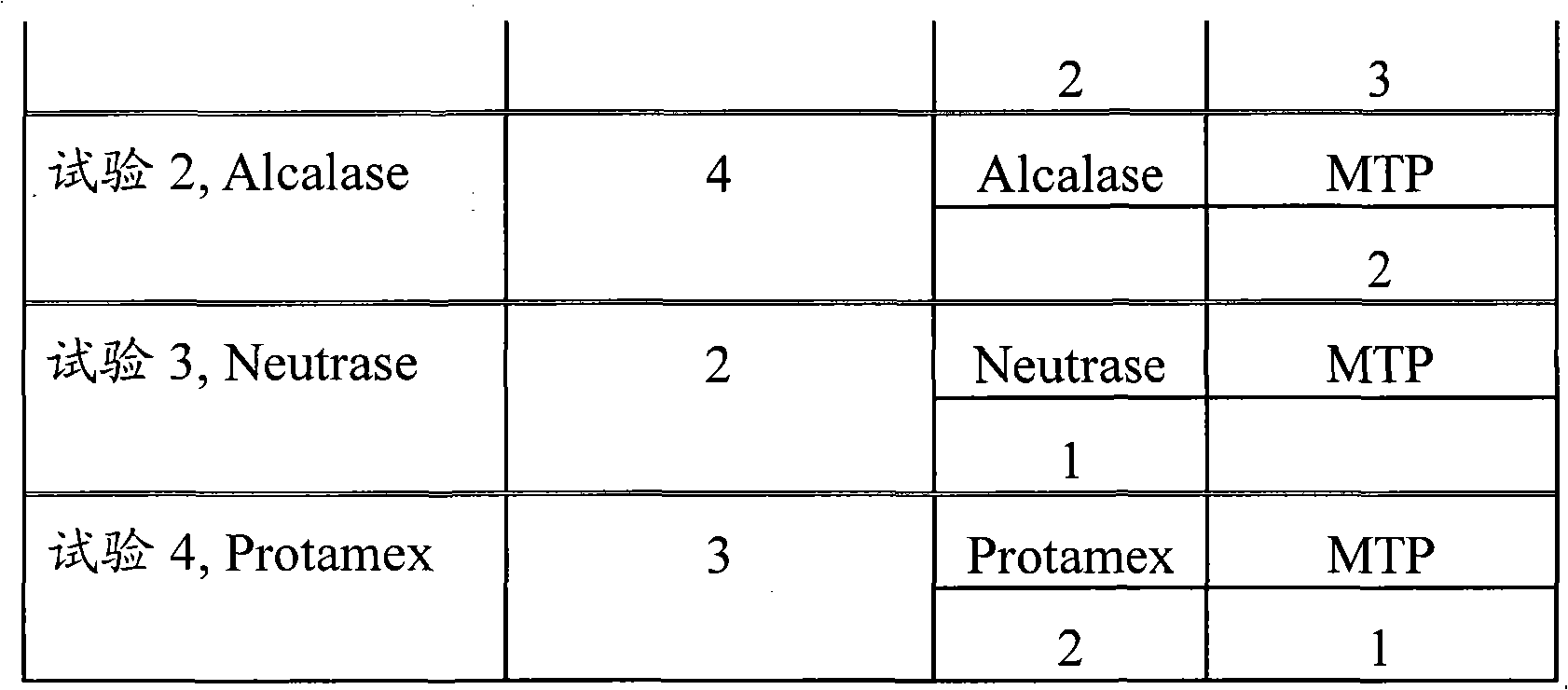

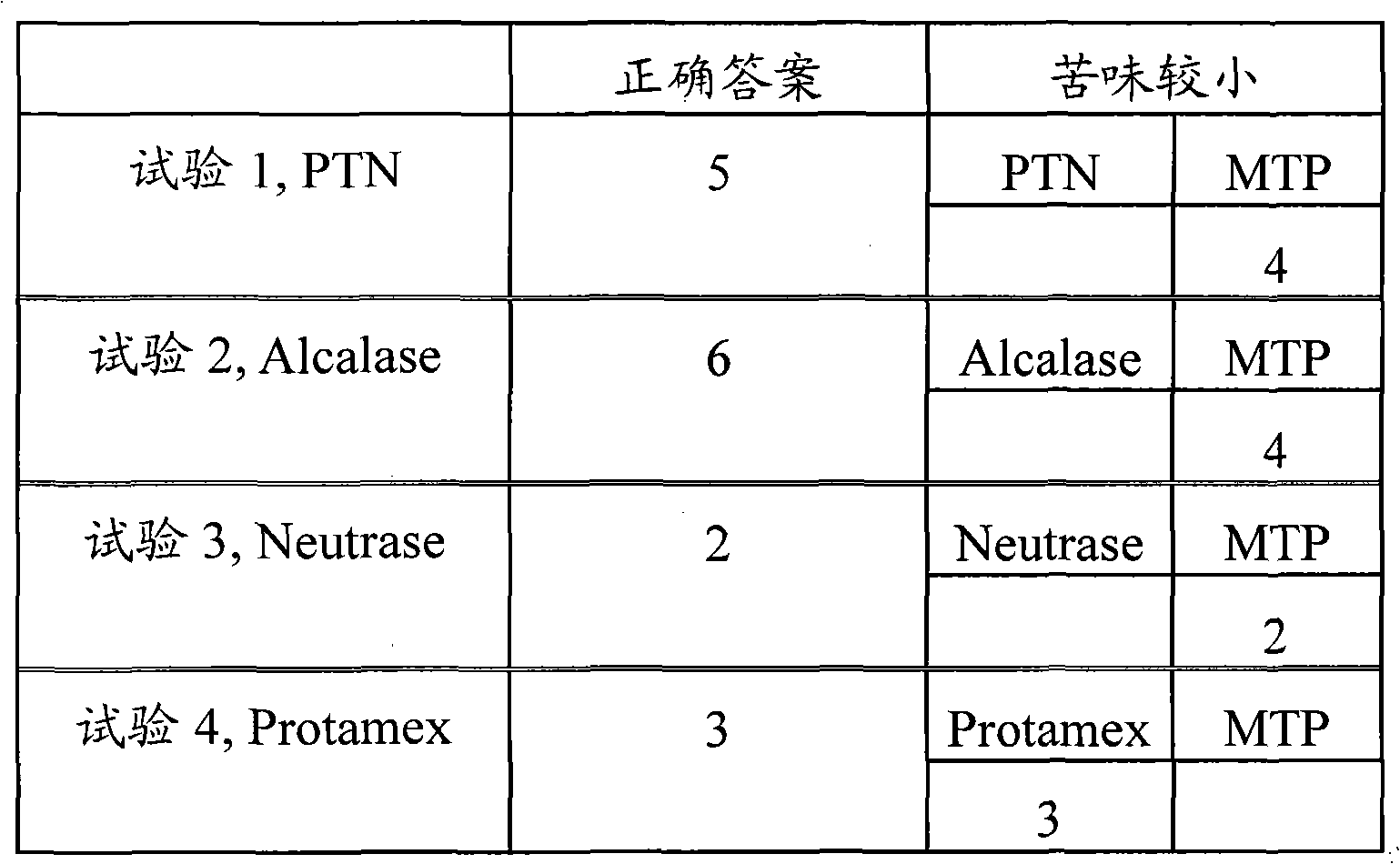

[0065] Samples were heated to 85°C to inactivate the enzyme and teste...

Embodiment 2

[0074] 5 different proteolytic enzymes were used to hydrolyze whey protein concentrate from Leprino Foods, US (containing approximately 80% protein in total dry matter). Enzymes and dosages are:

[0075] Trypsin-like protease from Fusarium oxysporum at a dose of 500 mg enzyme protein / kg raw material.

[0076] PTN 6.0 (Novozymes A / S), dosed at 0.5% of raw material.

[0077] Alcalase 2.4L (Novozymes A / S) at a dose of 0.2% of the starting material.

[0078] Neutrase 0.8L (Novozymes A / S) at a dose of 1% of the starting material.

[0079] Protamex 1.5MG (Novozymes A / S) at a dose of 0.5% of raw material.

[0080] The whey protein concentrate was mixed with water (1:9) before adding the enzymes.

[0081] Hydrolysis took place at 50°C in a beaker fitted with a base (0.1 N NaOH) dosing system to keep the pH constant at pH 7.5 until the degree of hydrolysis (DH) = 4%.

[0082] Samples were heated to 85°C to inactivate the enzyme and tested on a sensory panel.

[0083] A triplet te...

Embodiment 3

[0090] Definition, Measurement and Calculation of Trypsin Ratio

[0091] principle

[0092] To perform a measurable assay to measure trypsin-like endopeptidase activity, we used 10 different chromogenic substrates with the general formula Suc-AAPX-pNA where X is One-letter abbreviation for one of the 20 natural amino acid residues. The endopeptidase cleaves on the carboxy-terminal side of X and releases a measurable yellow color (p-nitroaniline). We used these 10 different Suc-AAPX-pNA substrates (X = A, R, D, E, I, L, K, M, F and V) available from Bachem for what we call trypsin Measurement and calculation of ratios.

[0093] A trypsin-like endopeptidase may be defined in the context of the present invention as an endopeptidase having a trypsin ratio greater than 100.

[0094] Trypsin ratios were calculated as the maximal activity on Suc-AAPR-pNA or Suc-AAPK-pNA divided by the maximal activity on any of the 8 other Suc-AAPX-pNA substrates:

[0095] Trypsin ratio = maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com