Method for preparing winding iron core and iron core therewith

A technology for winding iron cores and iron cores, applied in the field of iron core processing, can solve the problems that the metal lattice texture cannot be effectively reduced, the reduction performance cannot reach the optimum state, and the insulating coating cannot withstand high temperature, etc. Simple structure, good insulation performance, and the effect of improving interlayer insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

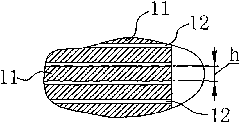

[0046] Example: see figure 1 , figure 2 with image 3 , a method for preparing a wound iron core provided by the present invention, which includes a strip-shaped non-oriented magnetic material 11, comprising the following steps:

[0047] (1) Preparation of mixed insulating paint 12: for uniform coating on the surface of the non-oriented magnetic material 11, so as to fully fill into the tiny gaps produced by the deformation of the non-oriented magnetic material 11, and penetrate into the non-oriented The inside of the magnetic material 11, and the non-oriented magnetic material 11 can be siliconized during the high temperature treatment process;

[0048] The specific steps are as follows:

[0049] (11) Preparation raw materials:

[0050] Prepare material A: prepare silicon oxide with a particle size of 1800-2200 mesh;

[0051] Prepare material B: prepare aluminum dihydrogen phosphate with a particle size of 1800-2200 mesh;

[0052] Preparation of material C: preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com