Aramid fiber III on-line thermal treating process and device thereof

A heat treatment device and aramid fiber technology, applied in textiles and papermaking, etc., can solve the problems of difficulty in further improving fiber strength, low fiber crystallinity, and poor fiber crystal orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

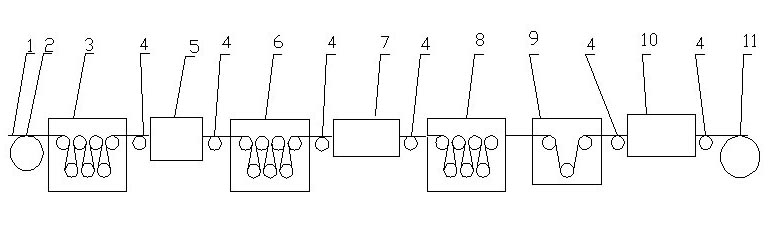

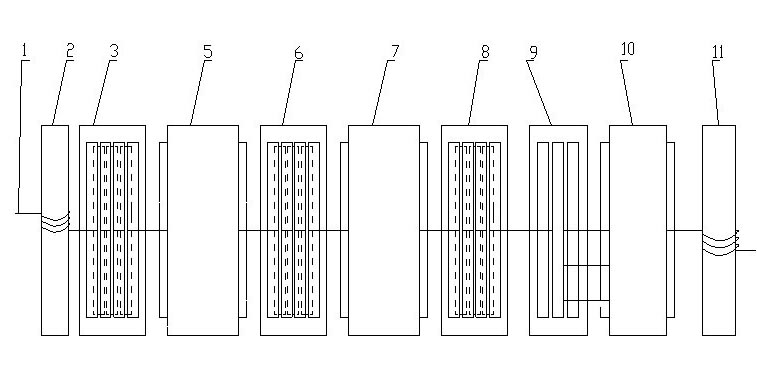

[0044] The on-line heat treatment device used in the process listed in this embodiment: includes the first tension roller 3, the first tunnel furnace 5, the second tension roller 6, the second tunnel furnace 7, the third tension roller 8, the oiler 9 and For the dryer 10, the first and second tunnel furnaces are respectively provided with a gas inlet and a heat medium inlet. Both the first tunnel furnace and the second tunnel furnace adopt square tube heating furnaces with an inner cavity width×height of 140×80mm and lengths of 5m and 3m respectively.

[0045] The process of using the aramid III on-line heat treatment device to perform on-line heat treatment on the aramid III fiber bundle includes the following steps:

[0046] (1) Preheating and stretching treatment: After the aramid fiber Ⅲ fiber strand comes out of the spinning and drying section, it is directly wound on the first tension roller, and the tow drawn from the first tension roller is introduced into the first tu...

Embodiment 2

[0053] The online heat treatment device of this example is the same as that of Example 1. Both the first tunnel furnace and the second tunnel furnace adopt square tube heating furnaces with an inner cavity width×height of 140×80mm and lengths of 5m and 3m respectively.

[0054] The process of using the aramid III on-line heat treatment device to perform on-line heat treatment on the aramid III fiber bundle includes the following steps:

[0055] (1) Preheating and stretching treatment: After the aramid fiber Ⅲ fiber strand comes out of the spinning and drying section, it is directly wound on the first tension roller, and the tow drawn from the first tension roller is introduced into the first tunnel furnace. After passing through the cavity of the first tunnel furnace, the fiber III is wound on the second tension roller, and N is passed into the furnace. 2 , heating up to about 190-200°C,

[0056] Adjust the rotating speed of the second tension roller greater than the first t...

Embodiment 3

[0062] The online heat treatment device of this example is the same as that of Example 1. Both the first tunnel furnace and the second tunnel furnace are square-tube heating furnaces with an inner cavity width×height of 140×80mm and lengths of 3m and 2m respectively.

[0063] The process of using the aramid III on-line heat treatment device to perform on-line heat treatment on the aramid III fiber bundle includes the following steps:

[0064] (1) Preheating and stretching treatment: After the aramid fiber Ⅲ fiber strand comes out of the spinning and drying section, it is directly wound on the first tension roller, and the tow drawn from the first tension roller is introduced into the first tunnel furnace. After passing through the cavity of the first tunnel furnace, the fiber III is wound on the second tension roller, and N is passed into the furnace. 2 , the temperature is raised to about 230-240°C to ensure that the fiber is stretched and heated in an oxygen-free state,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com