Hydrogen production method and device based on aluminum or magnesium underwater stir friction welding process

A technology of friction stir and welding process, which is applied in hydrogen production and other directions, can solve the problems of environmental pollution, high cost of hydrogen production, complicated process, etc., and achieve the effect of simple hydrogen production method, low hydrogen production cost and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

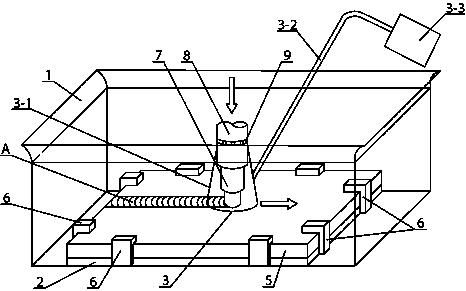

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is realized through the following steps: Step 1, install the aluminum plate or magnesium plate 5 of the workpiece to be welded: place the aluminum plate or magnesium plate 5 of the workpiece to be welded on the upper end surface of the stainless steel backing plate 2, and use the card The tool 6 firmly positions the aluminum or magnesium plate 5 of the welded workpiece and the stainless steel backing plate 2; Step 2, water injection: inject water into the water tank 1, and the water level exceeds the upper end surface of the aluminum or magnesium plate 5 of the welded workpiece by 30 mm to 50 mm; Step 3. Select the welding tool 7 parameters: the diameter of the stirring head shoulder on the welding tool 7 is 40 mm, the diameter of the stirring pin is 5 mm to 10 mm, and the length of the stirring pin is 5 mm to 10 mm; Step 4, install the welding tool 7: put the welding The clampi...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To describe this embodiment, the material of the collection cover 3-1 in Step 5 of this embodiment is plexiglass. Plexiglass is both transparent and visible, and it is not easy to break. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is composed of a water tank 1, a stainless steel backing plate 2 and a hydrogen gas collection assembly 3. The hydrogen gas collection assembly 3 is composed of a collection cover 3-1, an air guide tube 3-2 and a storage container 3-3. The air guide tube 3 - One end of -2 communicates with the collection cover 3-1, the other end of the air duct 3-2 communicates with the storage tank 3-3, the stainless steel backing plate 2 is placed on the bottom end surface of the water tank 1, and the hydrogen gas collection assembly 3 is located on the stainless steel backing plate 2, and the collection cover 3-1 on the hydrogen collection assembly 3 is placed perpendicular to the stainless steel backing plate 2.

[0013] Specific implementation mode four: combination figure 1 The present embodiment will be described. The collecting cover 3 - 1 of the present embodiment is conical, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com