Forming process of rear triangular pipe fitting and claw hook of composite material frame

A molding process and triangular tube technology, which is applied to bicycle accessories, bicycle brackets, transportation and packaging, etc., can solve the problems of long process time, drop, and smoothness of gaps at joints, so as to reduce the consumption of steps and time, Simple technical structure and improved dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

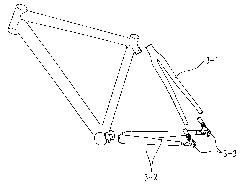

[0016] Specific Embodiment 1: Combining figure 1 , the rear seat stay pipe fitting 1-1, the rear chain stay pipe fitting 1-2, and the dropout claw 1-3 are preformed with carbon fiber composite materials, and placed in a mold to complete integral molding. Wherein the entire structure of the drop claw is integrally formed with the seat stay pipe fitting 1-1 and the seat stay pipe fitting 1-2 at one time.

specific Embodiment approach 2

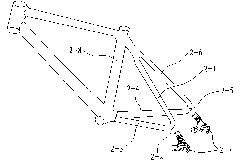

[0017] Specific Embodiment 2: Combining figure 2 , the left pipe fitting 2-1 of the rear upper fork, the left part of the hook 2-2, and the left lower fork pipe fitting 2-3, after the integrated preform of the carbon fiber composite material is completed, it is placed in the mold to complete the integral molding of the rough embryo. The right part 2-4 of the rear seat stay pipe, the hook claw 2-5 of the right part, and the right part 2-6 of the seat stay pipe are preformed integrally with carbon fiber composite materials, and then placed in the mold to complete the integral molding of the rough embryo. After the above steps are completed, the remaining hooks 2-7 are connected to the product end of the formed pipe fitting by means of screw locking.

specific Embodiment approach 3

[0018] Embodiment 3: Combining image 3 , the rear seat stay pipe fitting 3-1 is formed separately, the rear chain stay pipe fitting 3-2 and the dropout 3-3 are preformed integrally with carbon fiber composite materials, and then placed in the mold to complete the integral molding of the rear chainstay pipe fitting rough blank and the dropout , The chainstay pipe fittings can also be formed separately. After the seatstay pipe fittings and dropouts are preformed with carbon fiber composite materials, they are placed in the mold to complete the integral molding of the rear chainstay pipe fittings rough blank and the dropouts. The forming method in this method is that the claw can be integral or detachable as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com