Household stone milling machine

A household electric stone and pulp machine technology, which is applied in application, cocoa, grain processing, etc., can solve the problems of fast leaving speed, grinding disc wear, and loss of nutrients, so as to protect nutrients, reduce mechanical noise, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

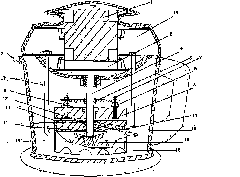

[0022] As a structural embodiment of a household electric stone refiner of the present invention, such as figure 1 As shown, the motor (1) and the reducer (2) are sealed and packaged to form the head (14), which is fixed on the cup body (3), and the output end is connected to the drive shaft (4) and the drive shaft (4) A smooth transmission (5), a movable grinding disc (8), a static grinding disc (10), and a vortex fan (19) are sequentially connected to form a whole.

[0023] The movable grinding disc (8) and the smooth transmission (5) are connected by screws (7), and a shock-absorbing spring (6) is clamped. It plays the role of damping and balancing the movable grinding disc (8), preventing the inclination of the movable grinding disc (8) due to uneven distribution of the friction surface between the movable grinding disc (8) and the static grinding disc (10) to achieve protection The function of the grinding disc prolongs the service life of the grinding disc.

[0024] The mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com