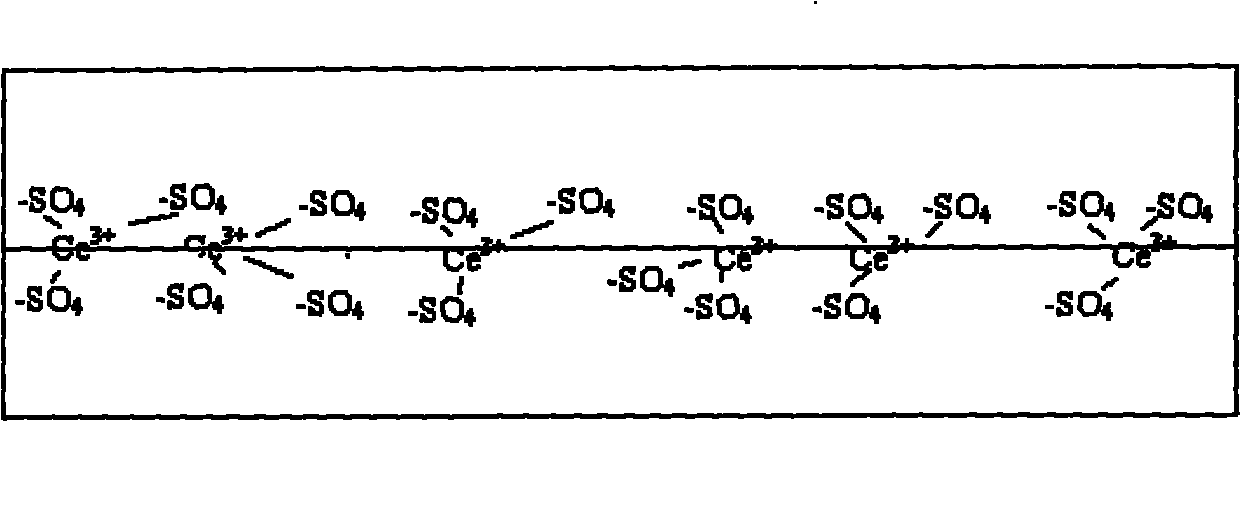

Doped and crosslinked multilayer perfluorinated ionic membrane and preparation method thereof

A perfluorinated ion and ion membrane technology, applied in the field of functional polymer composite materials, can solve the problems of reduced membrane strength, poor dimensional stability, and reduced equivalent value, and achieve improved high-temperature electrical conductivity, improved mechanical properties, and tight bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

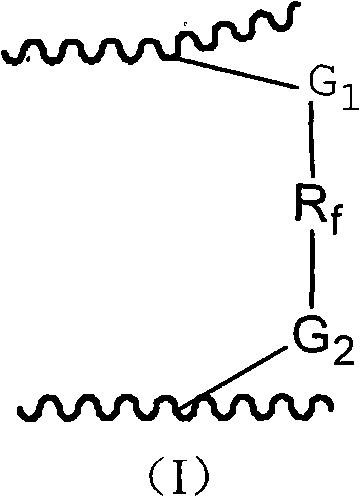

[0073] Convert the repeating unit to

[0074]

[0075] , polymer resin with EW=1000 and Zr(HPO 4 ) 2 (Zr(HPO 4 ) 2 The mass ratio of resin to resin is 3:100) mixed in propanol-water to obtain a solution, and then MnCO was added to the above solution 3 (accounting for 0.01% of the resin mass), make a total mass concentration of 5% propanol-water solution, then add it to the 5% perfluoromalonyl peroxide DMF solution, fully disperse and cast it to a horizontal position In the polytetrafluoroethylene casting mold, after vacuum drying at 80°C for 12 hours, the film was peeled off, and the molar concentration of 0.5M H 2 SO 4 The solution was boiled for 1 hour and washed with deionized water. After the heat treatment, the membrane was sequentially treated with NaOH solution and sulfuric acid solution to obtain a doped ion membrane (single-layer membrane 1#) with a cross-linking bridge (I). The above two single-layer perfluorinated cross-linked ion-doped membranes were stac...

Embodiment 2

[0077] Convert the repeating unit to

[0078]

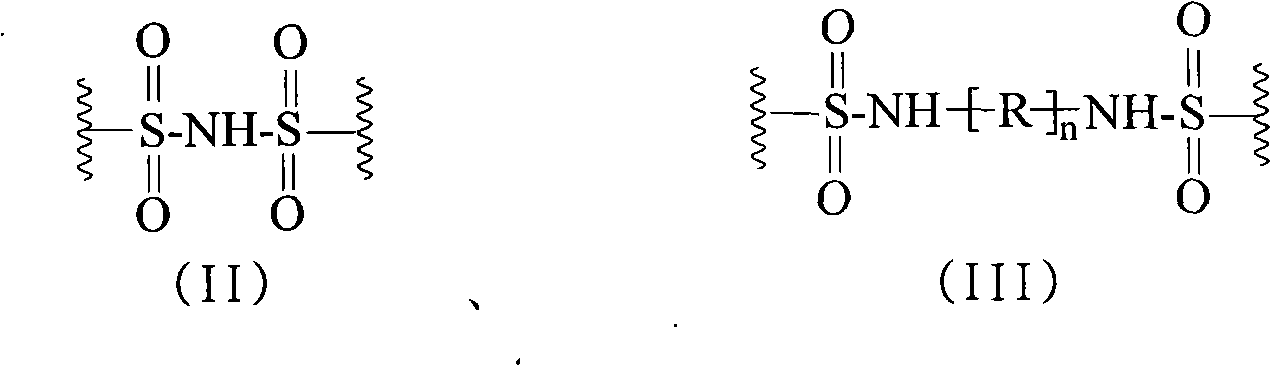

[0079] , polymer resin with EW=700, SiO with a particle size of 0.03 μm 2 (SiO 2 The mass ratio of perfluorosulfonic acid resin is 5:100) and Ce with perovskite structure x Ti (1-x) o 2 (x=0.4) The oxide (accounting for 2% of the mass of the resin) was fully extruded at 200° C. to obtain a film with a thickness of 30 μm. Soak the membrane in NH 4 Cl in DMF for 5 hours. The soaked membrane was then placed in triethylamine at 200 °C for 2 hours to obtain a crosslinked membrane. The membrane was sequentially treated with KOH solution and hydrochloric acid solution to obtain an ion exchange membrane (single-layer membrane 2#) with a cross-link bridge (II).

[0080] Place the above ionic membrane in the repeating unit as

[0081]

[0082] EW = 1200 polymer resin and tetraphenyl tin mixture, and at 270 ° C with a twin-screw extruder to obtain a film thickness of 50 μm, and then add the film at 230 ° C for 10 hours to obta...

Embodiment 3

[0084] Convert the repeating unit to

[0085]

[0086] , EW=1100 polymer resin and La 0.7 Ce 0.15 Ca 0.15 MnO 3 (accounting for 1% of the resin mass) and urea by hot pressing to obtain a film with a thickness of 100 μm. After heating the film at 170 ° C for 5 hours, it was treated with alkali and acid in sequence to obtain ions with cross-linking bridges (II) Membrane (single layer membrane 4#).

[0087] Convert the repeating unit to

[0088]

[0089] , polymer resin of EW=940, La-DMSO complex (accounting for 0.007% of resin mass) and H 3 PW 12 o 40 , by polymer resin with H3 PW 12 o 40 The ratio of the mass ratio of 100:20 was made into a DMSO solution with a mass concentration of 30%, and a film (monolayer film 5#) with a thickness of 10 μm was obtained by casting at 170° C. for 60 minutes.

[0090] The single-layer membranes 4# and 5# are stacked for hot pressing, and then hot-pressed with the multilayer membrane 2# to obtain a six-layer cross-linked doped i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com