Liquid environment protection energy-saving low-temperature filter and process thereof

An environmental protection, energy-saving, low-temperature filtration technology, applied in the direction of filtration separation, separation method, preparation of alcoholic beverages, etc., can solve problems such as increased difficulty and work intensity, greenhouse effect, and inability to maintain a constant temperature and orderly filtration, so as to improve production efficiency and product quality Quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

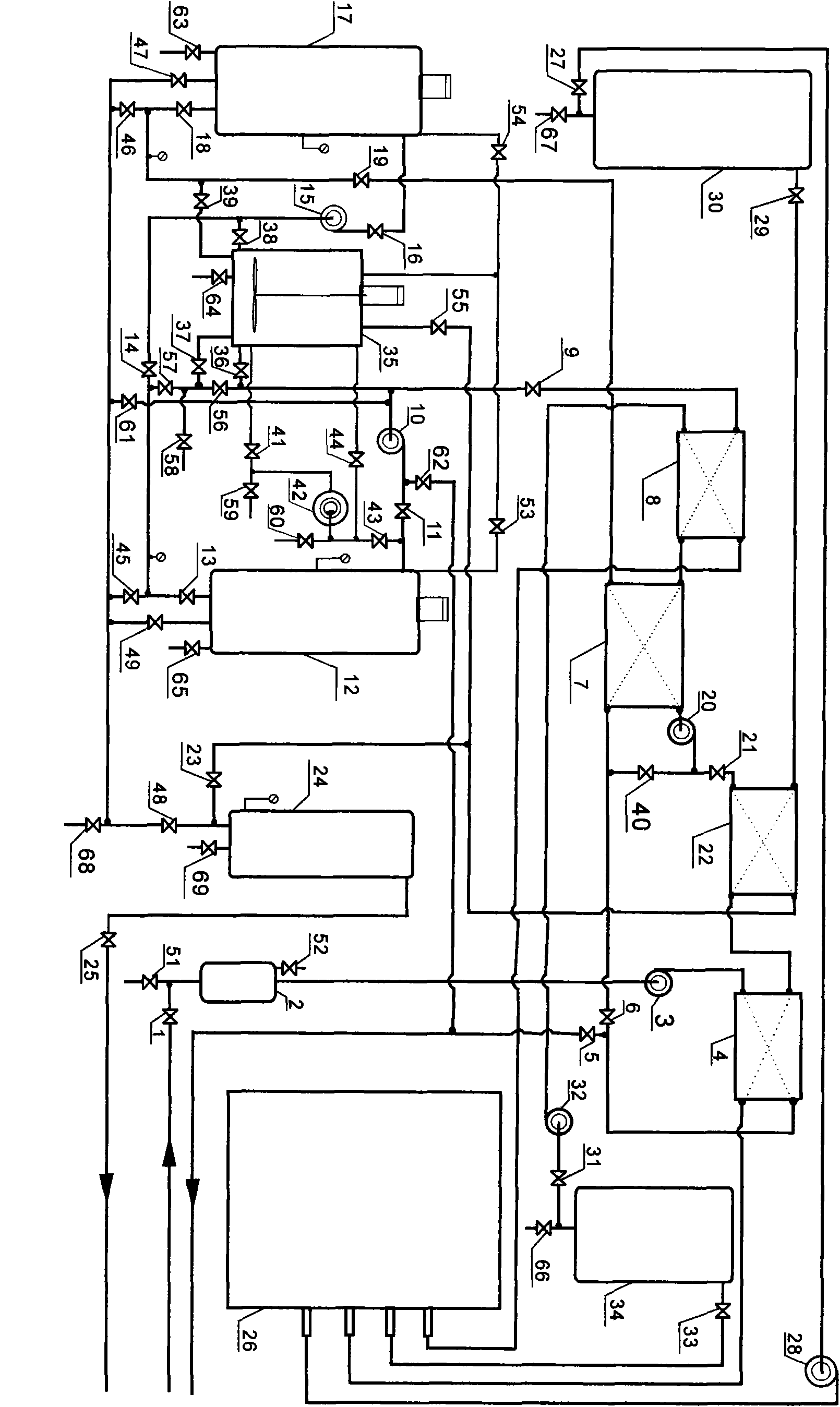

[0006] The present invention is described in further detail now in conjunction with accompanying drawing. refer to figure 1 , open valve 1, the raw liquid enters the inlet protection filter 2, opens valve 52 and closes its valve after the exhaust is full, starts the inlet pump 3, passes through the energy-saving exchanger 4, and simultaneously opens valve 6 to enter the energy-saving exchanger 7, energy-saving exchanger 8, Open valve 9, valve 11, open exhaust valve 53 stoste enters first filter machine 12 and close its valve after full load, open valve 13, valve 14, valve 16 simultaneously, open exhaust valve 54 stoste enters fine filter machine 17 and closes its after full load Valve, open valve 18, valve 39 at the same time, flow into stirring device 35 and close valve 39 with full load, open valve 19 at the same time and enter energy-saving exchanger 7, open valve 40, close valve 6 and open and return raw liquid valve 5 at the same time; The filter 17 performs a small circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com