Locking bone fracture plate for far back outer side of humerus

A bone plate, posterolateral technology, applied in the field of orthopaedic internal fixation bone plate, can solve the problems of difficult operation of the distal humerus lateral plate D, unfavorable doctor's operation, and high requirements for reducing trauma, so as to reduce the loss of one reduction and improve the cure rate. , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

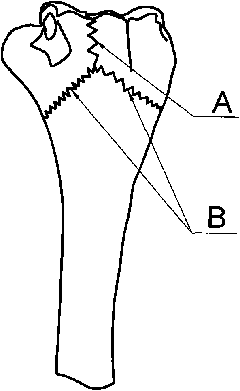

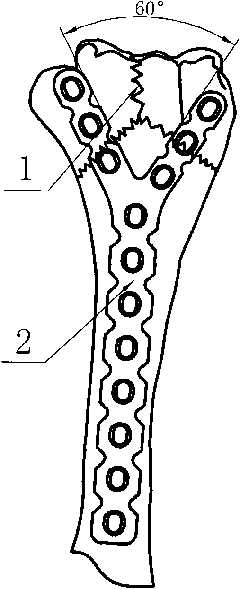

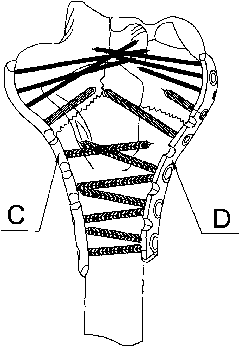

[0027] Such as Figure 4 , 5 , 6a, 6b and Figure 7a , 7b , 7c, a posterolateral distal humerus locking bone plate, which includes a head 1 and a body 2, and the head 1 and body 2 are integrally structured. The head 1 is wider than the body 2 . The body part 2 is straight, and the head 1 is extended from the upper end of the body part 2, and takes the center line of the body part as the axis-while extending, helically rotates and deviates toward the posterolateral E side of the distal end of the humerus. When rotating about 1 / 4 of a circle (that is, when the top of the steel plate head is basically perpendicular to the body of the steel plate), the rotation deviation L of the small plane at the top of the steel plate head 1 (the plane of the head and the centerline of the body) reaches 25-30mm (See Figure 7b ). When the bone plate with such a shape is in use, the body can be attached to the shaft of the humerus, and the head 1 can be attached to the fan-shaped posterior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com