Electrical structure of solid combination switch

A composite switch and electrical technology, applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of inability to apply high-voltage systems, small reactive power compensation capacity, low electrical insulation capacity, etc., and achieve floor space Small size, less external wiring, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in conjunction with the accompanying drawings.

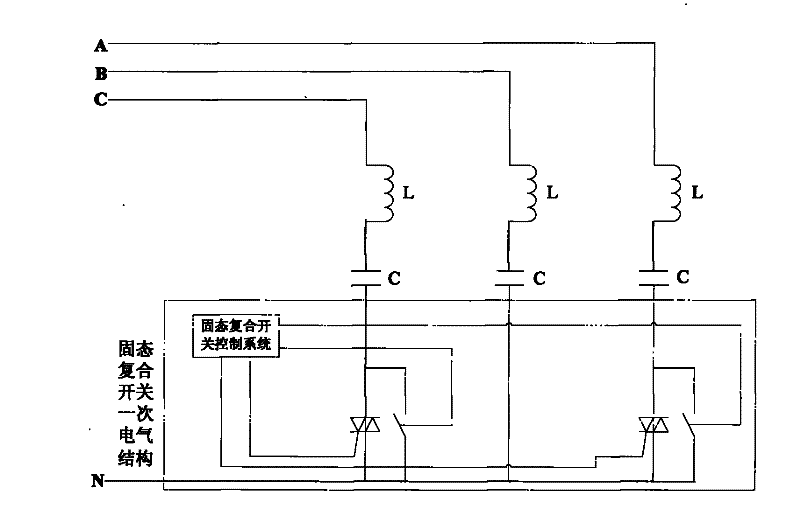

[0021] figure 1 It is the electrical structure diagram of the primary system of the solid-state composite switch. In the figure, A, B, and C are the three-phase buses of the system, and N is the neutral point of the filter branch of the capacitor bank. The three-phase busbars are respectively connected to reactors, and then the reactors and capacitors are connected in series. The outlets of the A and C two-phase capacitors are connected to the first end of the thyristor valve string, and the thyristor valve string is connected in parallel with the contactor. Terminal and B-phase capacitor outlet are shorted. This connection method is mainly aimed at the synchronous switching method of the three-phase capacitor bank. When the contactor is disconnected and the thyristor is not triggered, the B phase cannot form a current loop with other phases, so the B phase capacito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com