Plane light source device and preparation method thereof

A flat light source and device technology, applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of low luminous brightness and have not been widely commercialized, and achieve the effect of improving the brightness of the light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

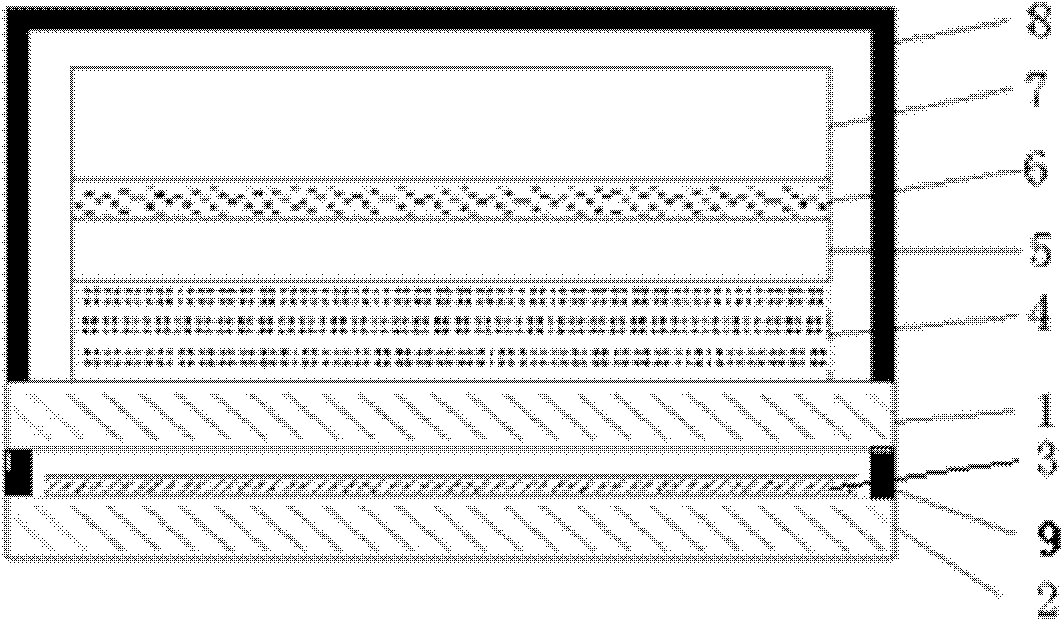

[0023] Example 1, please refer to figure 1 :

[0024] Step 1: Weigh 5g of ethyl cellulose and 45g of terpineol, put them in a clean beaker, stir at a constant temperature of 70°C-80°C for 2-3h, prepare a carrier, and transfer it to a mortar;

[0025] Step 2: Weigh 50g of CCFL phosphor, the particle size of which is 6.8μm, 0.3g of BYK171 dispersant, 0.4g of hydroxydimethylsiloxane as defoaming agent, and 1g of silicon dioxide, of which , the particle size of silicon dioxide is less than 1 μm, put it into a mortar filled with the above-mentioned carrier and grind together for half an hour to make a phosphor powder slurry for later use;

[0026] The third step: the lower glass substrate 2, which is ultra-clear glass used in this embodiment, is cleaned with detergent and dried, and then printed on it with a thickness of 10 μm prepared in the second step by screen printing. phosphor paste, thereby forming a phosphor layer 3;

[0027] The 4th step: A) will have the upper glass su...

Embodiment 2

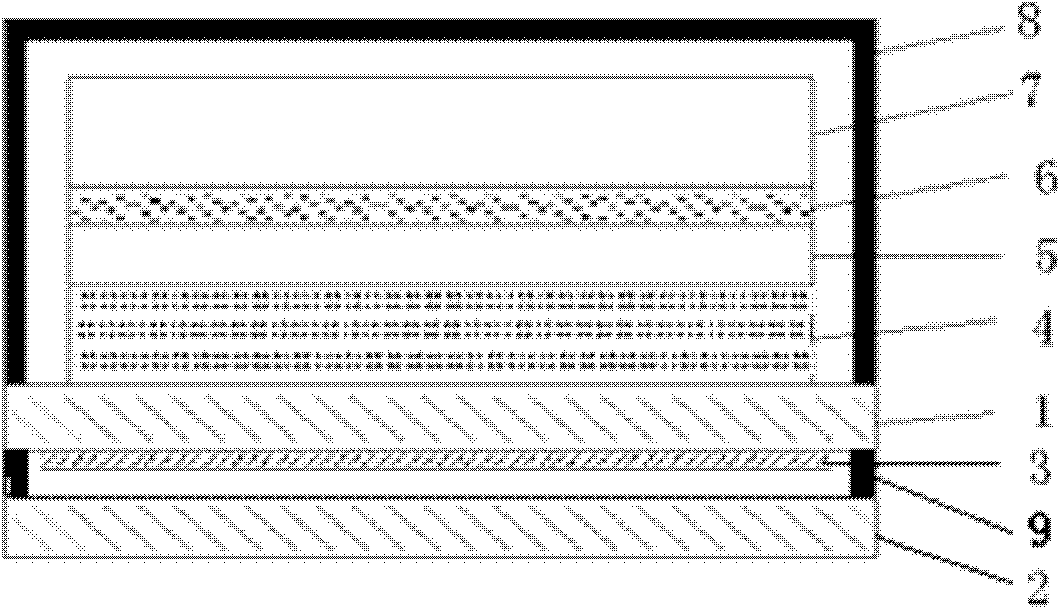

[0033] Example 2, please refer to figure 2 Shown:

[0034] The difference between this embodiment and Embodiment 1 is that the phosphor layer 3 is prepared on the lower surface of the upper glass substrate 1, that is, the upper glass substrate 1 with indium tin oxide (ITO) is cleaned and dried on the upper glass substrate. 1 Print a layer of phosphor paste on the side without the ITO conductive layer by screen printing, thereby forming a phosphor layer 3 with a thickness of 10 μm. The other production processes are the same, and will not be repeated here.

[0035] Table 1 is a comparison of relevant data between the light source device of the present invention and the traditional light source device, wherein A1-A3 are traditional light sources, that is, planar dielectric barrier discharge light sources, and B1-B3 are planar light sources of the present invention:

[0036] Table 1

[0037] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com