Connection table based automatic optical detection algorithm of printed circuit board

A printed circuit board, optical detection technology, applied in the direction of material analysis, measuring device, scientific instrument, etc. by optical means, to achieve the effect of shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

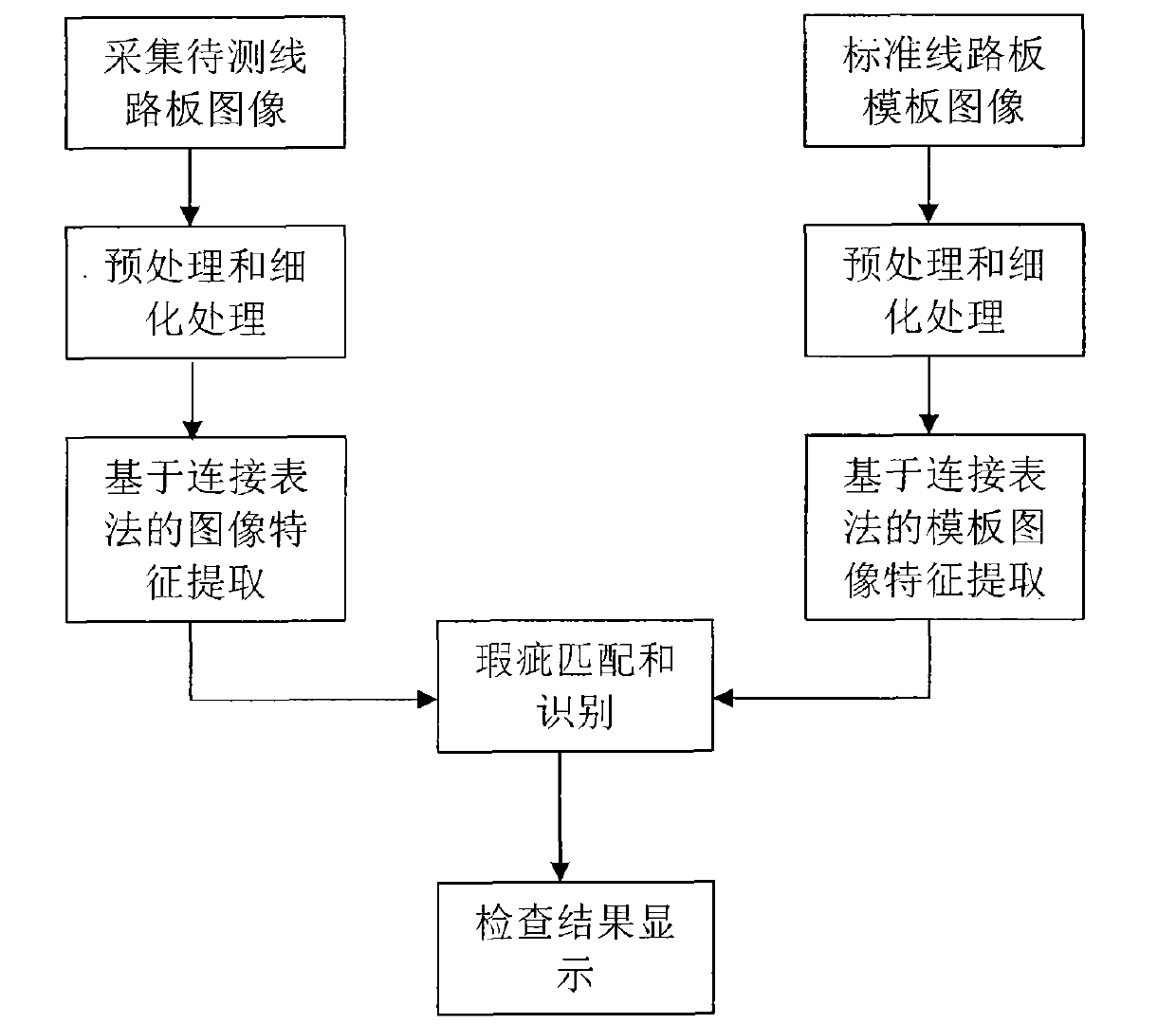

Method used

Image

Examples

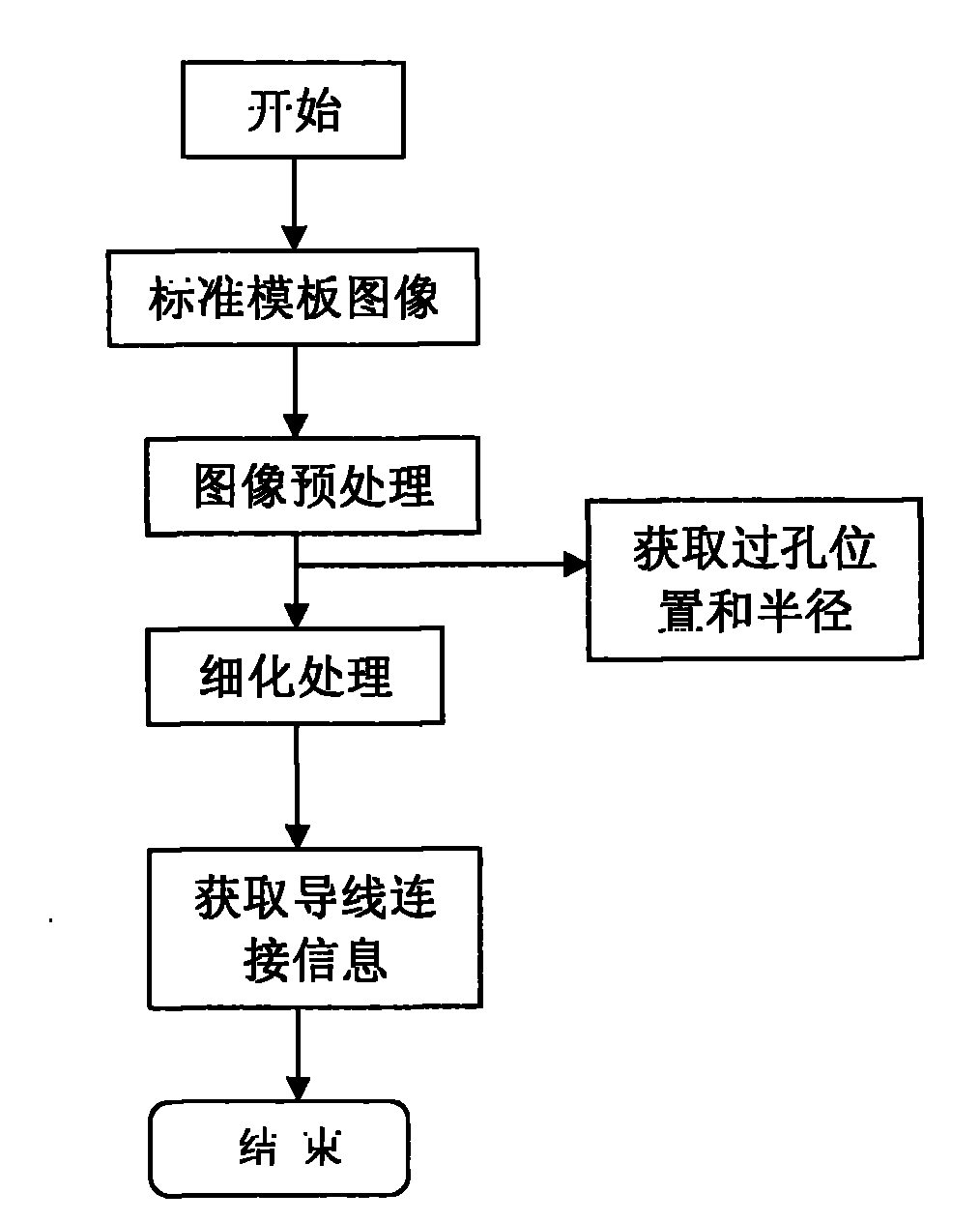

Embodiment Construction

[0026] Filter processing: Median filtering is adopted, and the window scanning path adopts an S shape, that is, the window moves to the right first, and when it reaches the rightmost end, the window moves down by one pixel, and then the window moves to the left, and when it reaches the leftmost end, the window moves down Move one pixel, then move to the right, and cycle the scan until the entire image is scanned. When the window moves one pixel, the local histogram in the window does not need to be re-stated. When the window moves to the right, only the leftmost pixel of the window is subtracted from the histogram, and the pixels in the right column outside the window are added; When the end of a row is reached, instead subtract the pixels in the top row of the window from the histogram and add the pixels in the next row outside the window; Subtract from the middle, and add the pixels in the left column outside the window at the same time.

[0027] In the feature extraction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com