Method for producing feed grade ferrous sulfate monohydrate from titanium pigment waste acid condensed slag

A technology of titanium dioxide waste acid and water ferrous sulfate, applied in the direction of ferric sulfate, etc., to achieve the effect of facilitating industrial production, saving resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

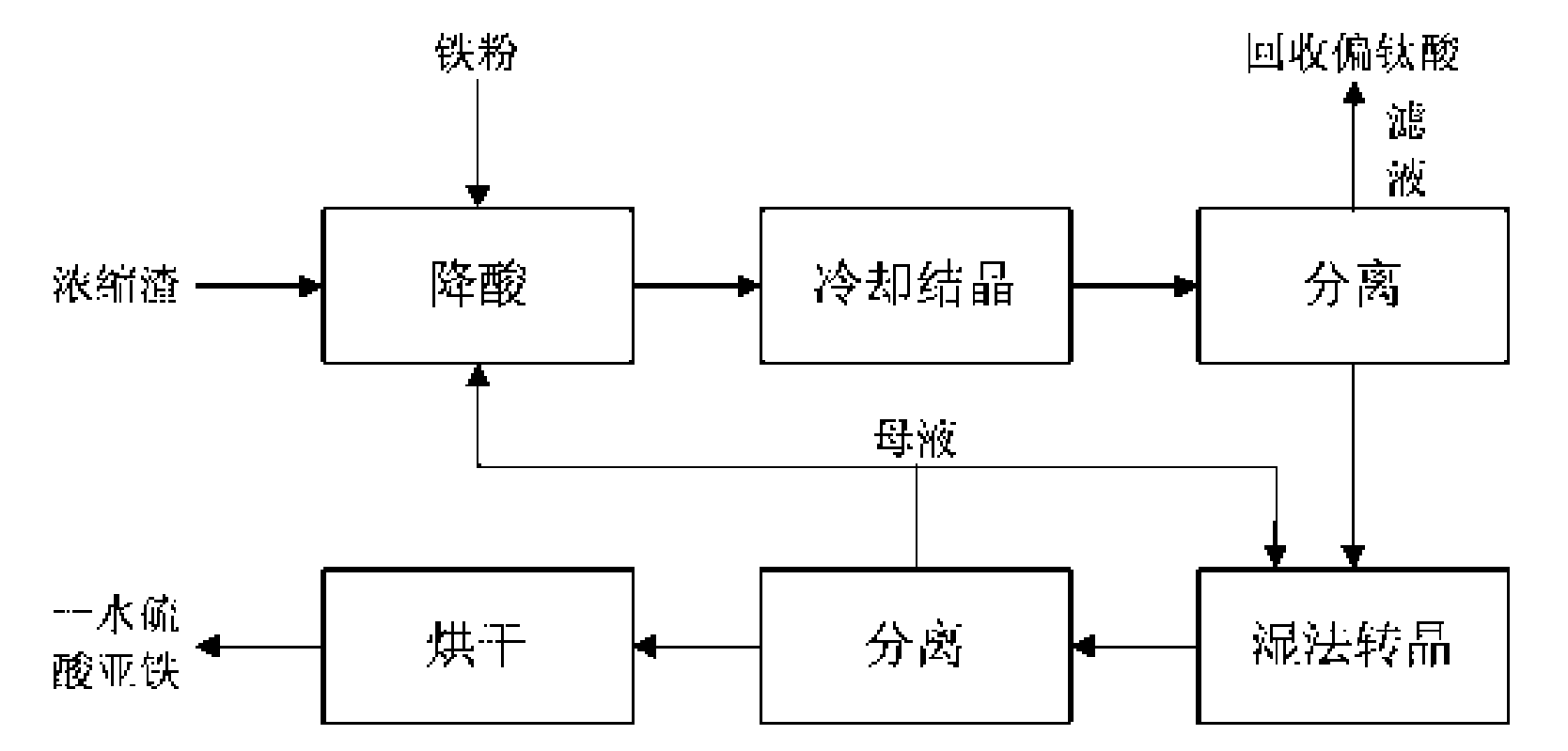

[0038] The process flow chart of this embodiment refers to the appended figure 1 , including the following process steps:

[0039] (1) concentrated slag acid reduction:

[0040] In the FRP reactor, add 4m 3 Ferrous sulfate monohydrate precipitates the mother liquor (7.18% of iron content, 2.34% of acid content) that crystallization produces, under stirring state, add 6 tons of particle diameters again and be the concentrated slag of titanium white waste acid of 2~20 μ m (Fe16%, H 2 SO 4 14%), mix the concentrated slag with the mother liquor, control the specific gravity of the slurry to 1.2, raise the temperature to 60-70°C, turn on the fan, and then slowly add 320kg of iron powder. The iron powder addition time is about 3 hours. After the iron powder reaction is completed, then join 2m 3 Wet ferrous sulfate monohydrate mother liquor, and maintain the temperature. At this time, the iron content of the slurry is 13.01%, and the acid content is 3.96%.

[0041] (2), coolin...

Embodiment 2

[0046] The process flow chart of this embodiment refers to the appended figure 1 , including the following process steps:

[0047] (1) concentrated slag acid reduction:

[0048] In the FRP reactor, add 4m 3 The mother liquor (7.18% of iron content, 2.34% of acid content) produced by ferrous sulfate monohydrate precipitation crystallization, under stirring state, add 6 tons of titanium white waste acid concentration slag (Fe16%, H 2 SO 4 14%), mix the concentrated slag with the mother liquor, control the specific gravity of the slurry to 1.4, raise the temperature to 80-90°C, turn on the fan, and then slowly add 200kg of iron powder. The iron powder addition time is about 2 hours. After the iron powder reaction is completed, add another 2m 3 Wet ferrous sulfate monohydrate mother liquor, and maintain the temperature. At this time, the iron content of the slurry is 12.36%, and the acid content is 5.35%.

[0049] (2), cooling crystallization, separation:

[0050] The slur...

Embodiment 3

[0054] The process flow chart of this embodiment refers to the appended figure 1 , including the following process steps:

[0055] (1) concentrated slag acid reduction:

[0056] In the FRP reactor, add 6m 3 The mother liquor (7.18% of iron content, 2.34% of acid content) produced by ferrous sulfate monohydrate precipitation crystallization, under stirring state, add 6 tons of titanium white waste acid concentration slag (Fe16%, H 2 SO 4 14%), mix the concentrated slag with the mother liquor, control the specific gravity of the slurry to 1.2-1.4, raise the temperature to 50-60°C, turn on the fan, and then slowly add 390kg of iron powder. The iron powder addition time is about 4 hours, and the iron powder reaction is completed. After that, add another 2m 3 Wet ferrous sulfate monohydrate mother liquor, and maintain the temperature. At this time, the iron content of the slurry is 12.47%, and the acid content is 3.04%.

[0057] (2), cooling crystallization, separation:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com