Method for preparing manganese polysilicate doped manganese dioxide adsorbent

A polymanganese silicate and manganese dioxide technology, applied in chemical instruments and methods, silicon compounds, adsorbed water/sewage treatment, etc., can solve the problems of poor sedimentation, poor dimethylamine removal ability, etc., and achieve high self-stability , Easy to recycle, uniform and dense particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

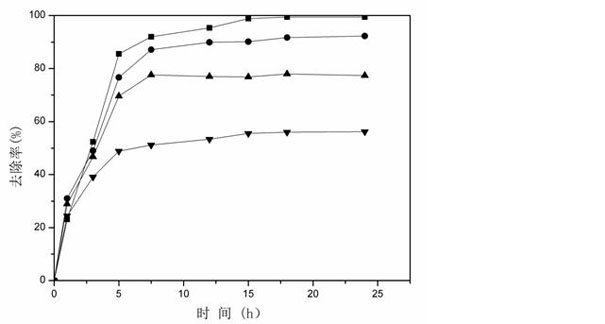

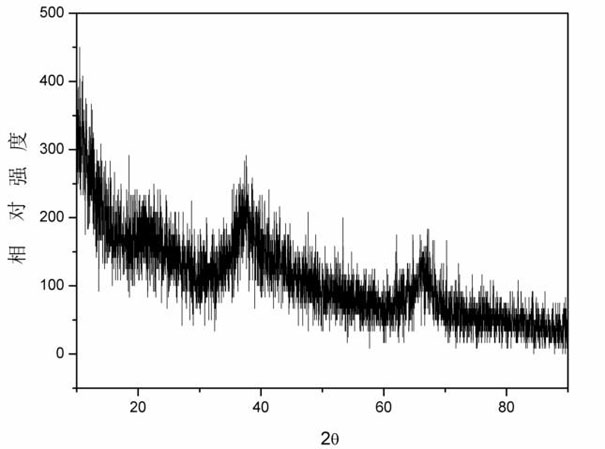

[0010] Specific embodiment one: the preparation method of polysilicate manganese salt doped manganese dioxide adsorbent in the present embodiment is as follows: one, according to potassium permanganate and sodium salt molar ratio is the ratio of 1.6~4:1, with 100r / Add the potassium permanganate solution dropwise into the sodium salt solution while stirring at a stirring speed of 100r / min to 300r / min, and then continue stirring for 30min at a stirring speed of 100r / min to 300r / min to obtain product A; The mass ratio of silicate to silicate is 1:1. Add silicate to product A, settle for 10min~30min, activate at 40℃~60℃ for 24h~48h, then remove the upper layer of clear solution, use Wash the precipitate with deionized water until the pH of the washing solution is 8-10, and then dry the precipitate at 60°C to obtain product B; 3. Add deionized water to product B until product B is cracked into granules, Then wash with deionized water several times to remove suspended matter, and t...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the molar ratio of potassium permanganate to sodium salt in step 1 is 2-3:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the molar ratio of potassium permanganate to sodium salt in step 1 is 2.5:1. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com