Measuring method of aluminum alloy CCT (Continuous Cooling Transformation) diagram

A determination method and technology of aluminum alloy, applied in the investigation stage/state change and other directions, can solve the problems of inability to shield the electrode contact measurement accuracy, unstable relative resistance value change data, inability to accurately reflect the phase transformation process, etc., to reach the phase transition point. Accurate and reliable, cost and time saving, fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Measuring alloy grade: 7A04 aluminum alloy

[0031] Step 1: Determination of aluminum alloy voltage and temperature change data with time under different cooling systems

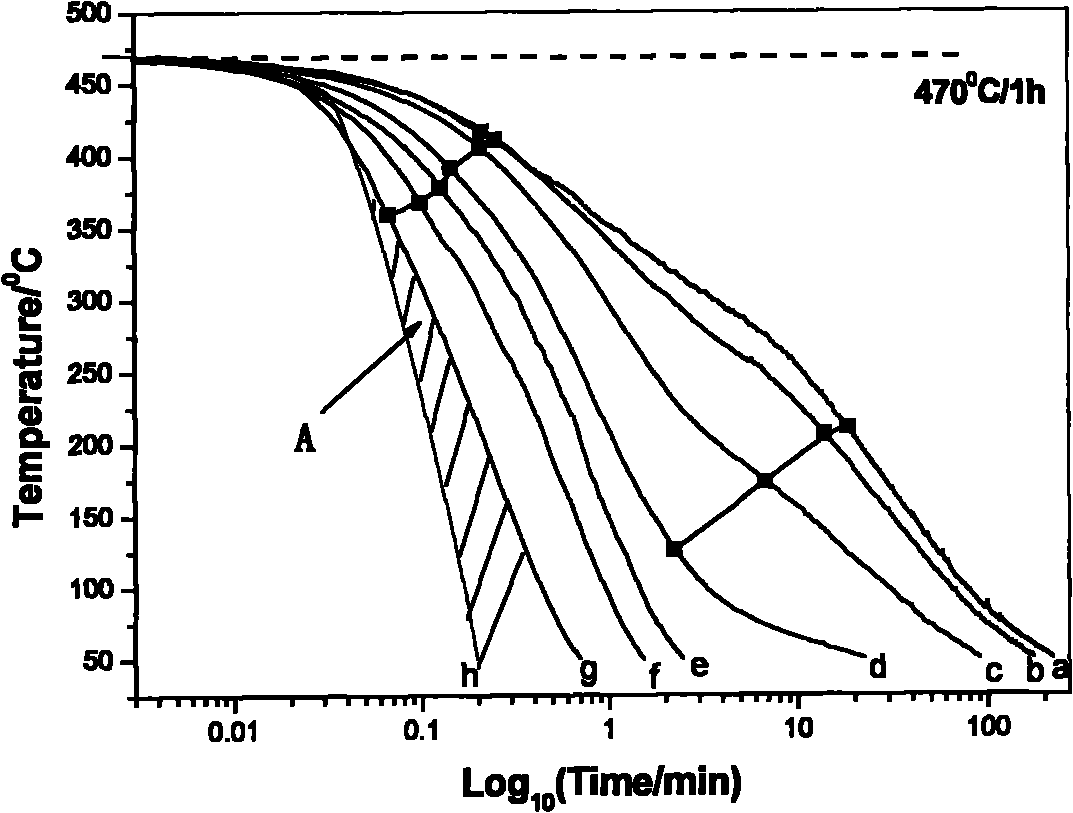

[0032] Select 470°C / 1h as the solid solution process for 7A04 alloy CCT diagram measurement, pass a constant current of 5A to the fully solidified aluminum alloy sample, and adopt furnace cooling, air cooling, air cooling, and liquid nitrogen cooling systems for aluminum alloy samples. Cooling, using dynamic resistance strain gauges and thermocouples to measure the data of sample voltage and temperature changing with time in real time;

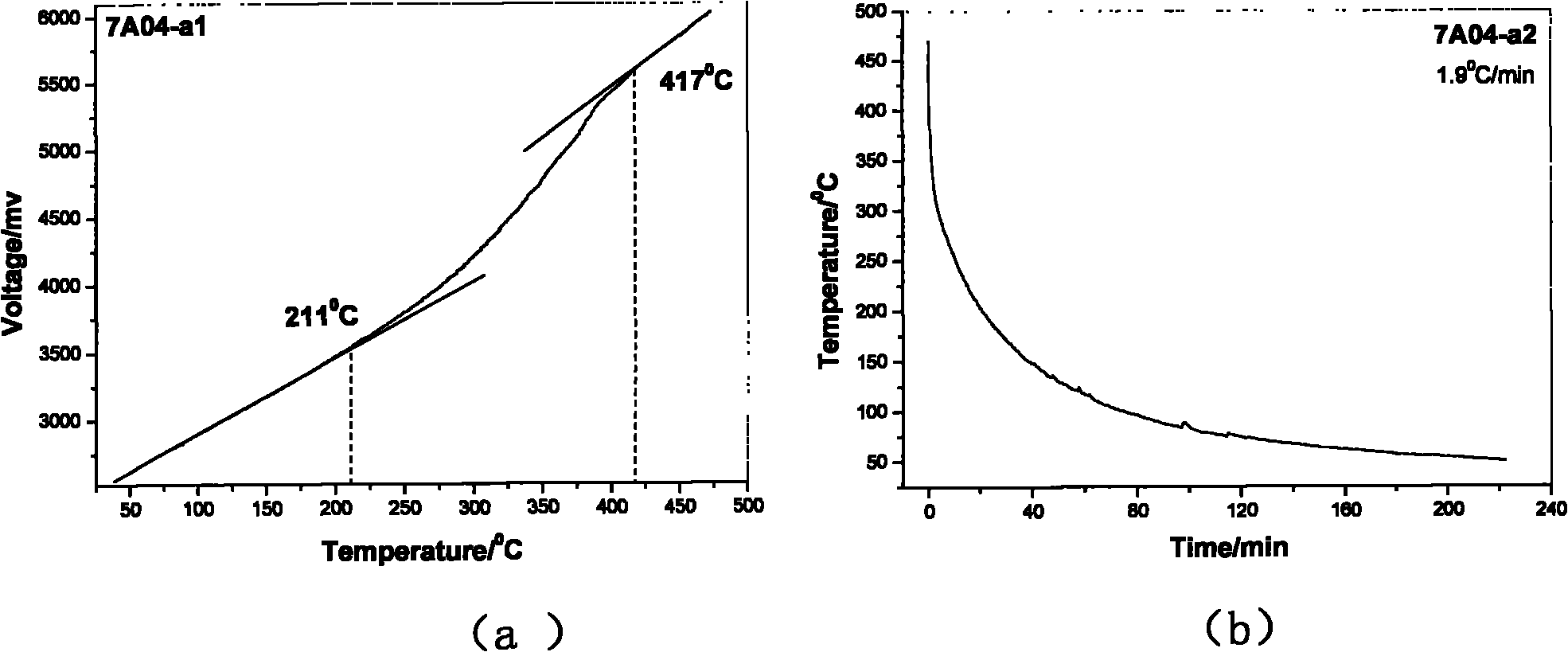

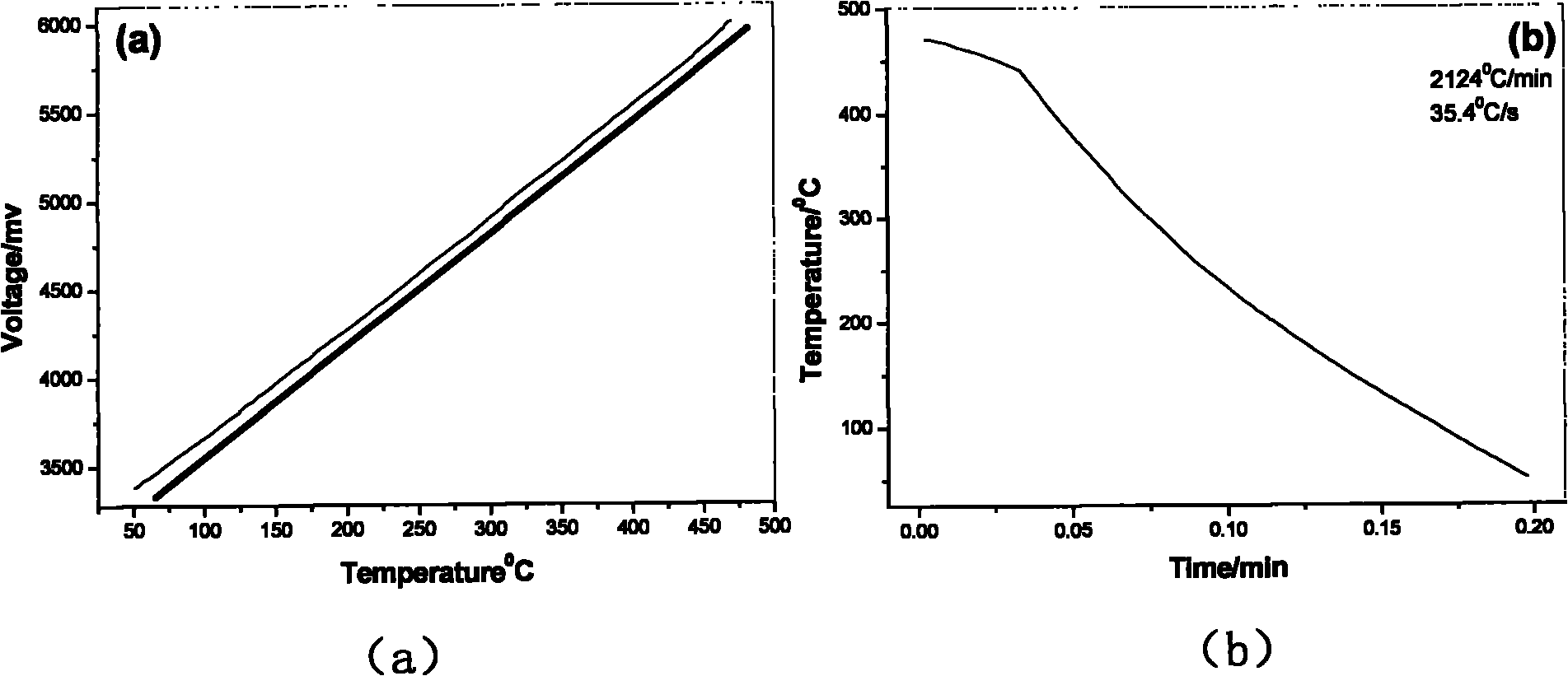

[0033] Step 2: According to the data obtained in the first step, draw the voltage-temperature curve and temperature-time curve during the cooling process of the sample; among them, the curve under the partial cooling system is shown in the appendix figure 1 a. attached figure 1 b. attached figure 2 a. attached figure 2 b;

[0034] The third step: det...

Embodiment 2

[0041] Embodiment 2: Measuring alloy grade: 01970 aluminum alloy

[0042] Step 1: Determination of aluminum alloy voltage and temperature change data with time under different cooling systems

[0043] Select 470°C / 1h as the solid solution process for 01970 alloy CCT map measurement, pass a constant current of 5A to the fully solid-soluted aluminum alloy sample, and adopt furnace cooling, air cooling, air cooling, and liquid nitrogen cooling systems for aluminum alloy samples. Cooling, using dynamic resistance strain gauges and thermocouples to measure the data of sample voltage and temperature changing with time in real time;

[0044] Step 2: According to the data obtained in the first step, draw the voltage-temperature curve and temperature-time curve during the cooling process of the sample; among them, the curve under the partial cooling system is shown in the appendix Figure 4 a. attached Figure 4 b. attached Figure 5 a. attached Figure 5 b;

[0045] The third ste...

Embodiment 3

[0052] Embodiment 3: Measuring alloy grade: 6061 aluminum alloy

[0053] Step 1: Determination of aluminum alloy voltage and temperature change data with time under different cooling systems

[0054] Select 530°C / 3h as the solid solution process for 6061 alloy CCT map measurement, pass a constant current of 5A to the fully solidified aluminum alloy sample, and adopt furnace cooling, air cooling, air cooling, and liquid nitrogen cooling systems for aluminum alloy samples. Cooling, using dynamic resistance strain gauges and thermocouples to measure the data of sample voltage and temperature changing with time in real time;

[0055] Step 2: According to the data obtained in the first step, draw the voltage-temperature curve and temperature-time curve during the cooling process of the sample; among them, the curve under the partial cooling system is shown in the appendix Figure 7 a. attached Figure 7 b. attached Figure 8 a. attached Figure 8 b;

[0056] The third step: de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com