Induction heating ultra-temperature continuous carbonization furnace

An induction heating and carbonization furnace technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve problems affecting product quality, slow cooling speed, short furnace life, etc., to achieve good product quality, fast cooling speed, and high output high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

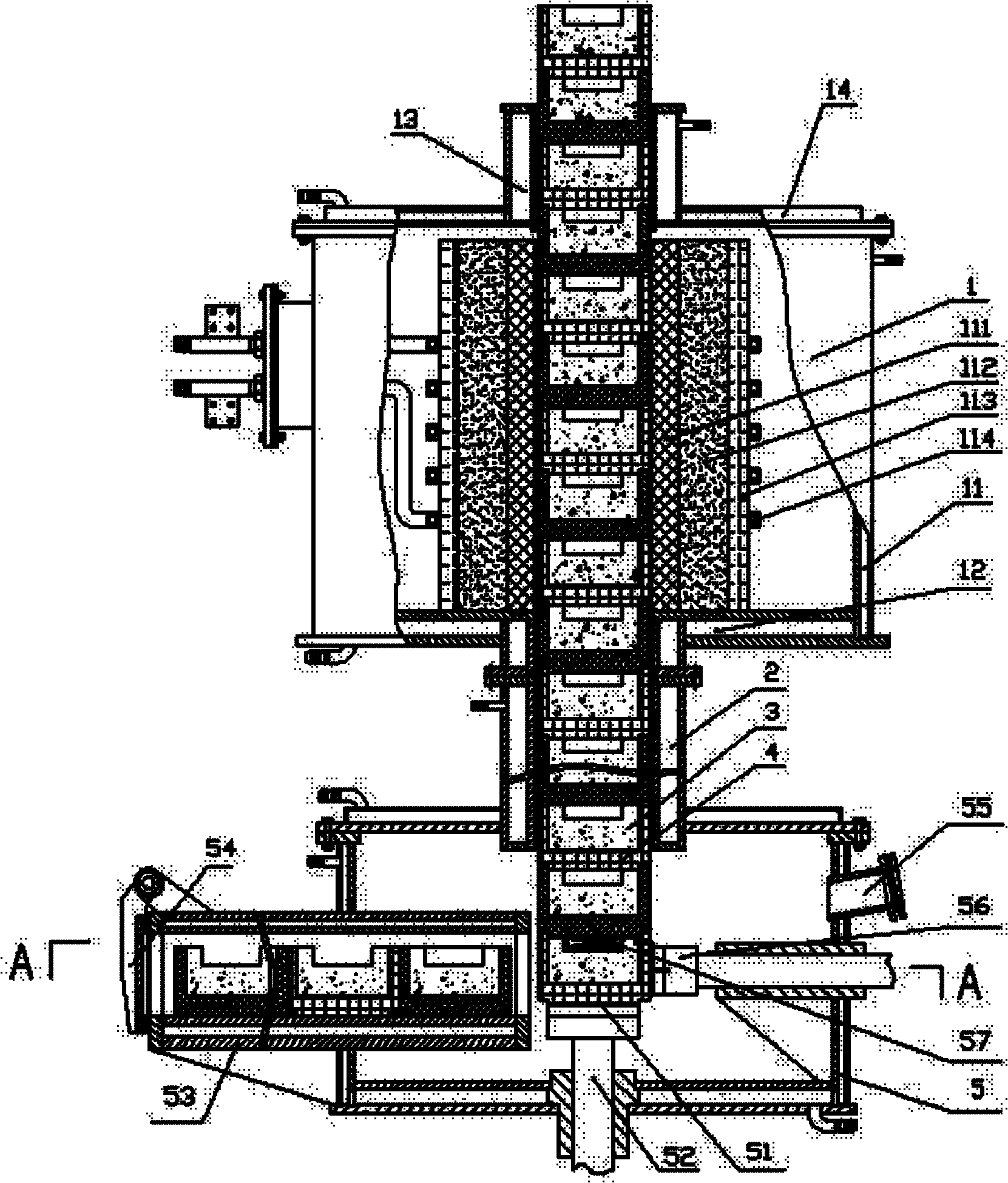

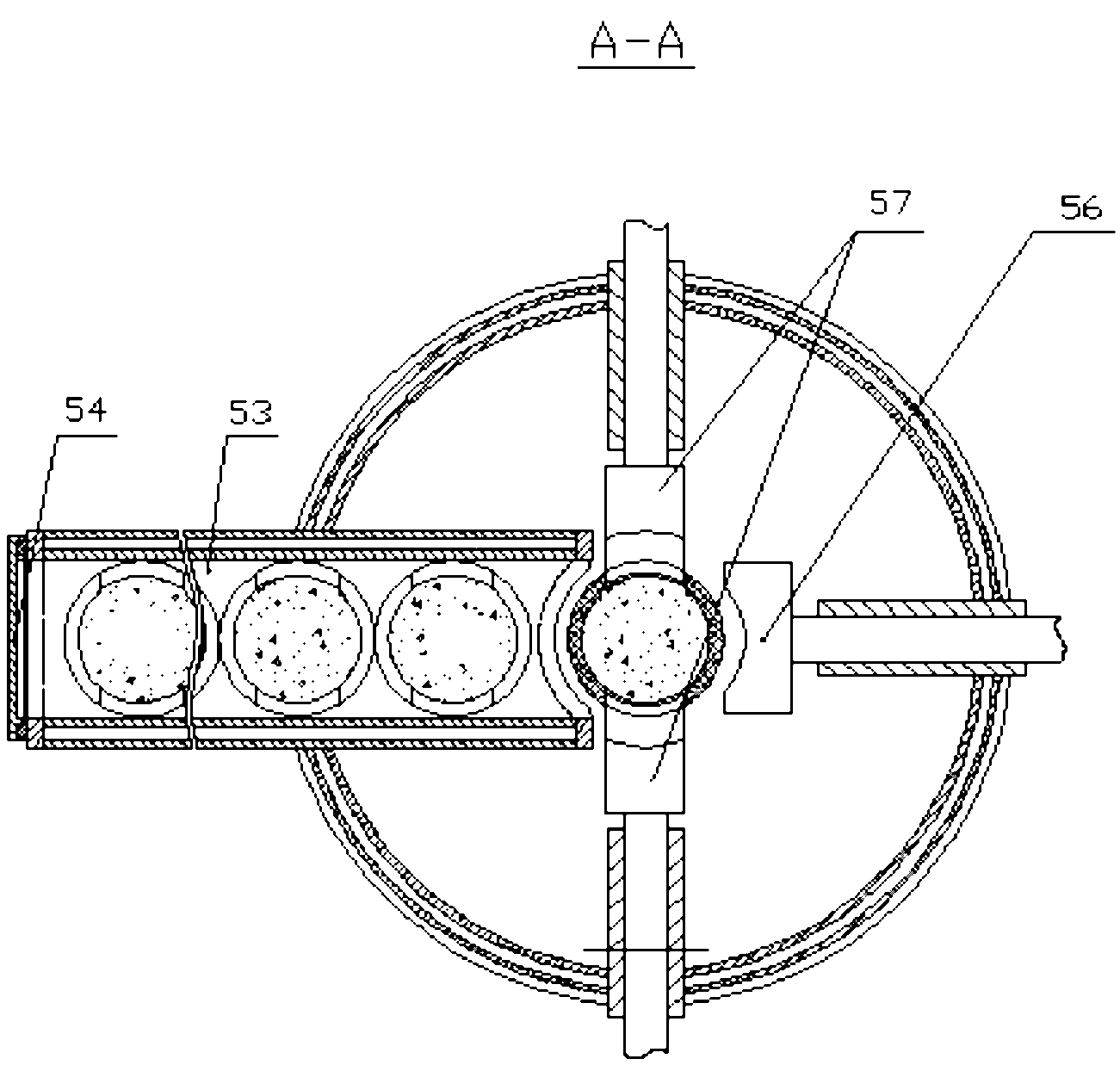

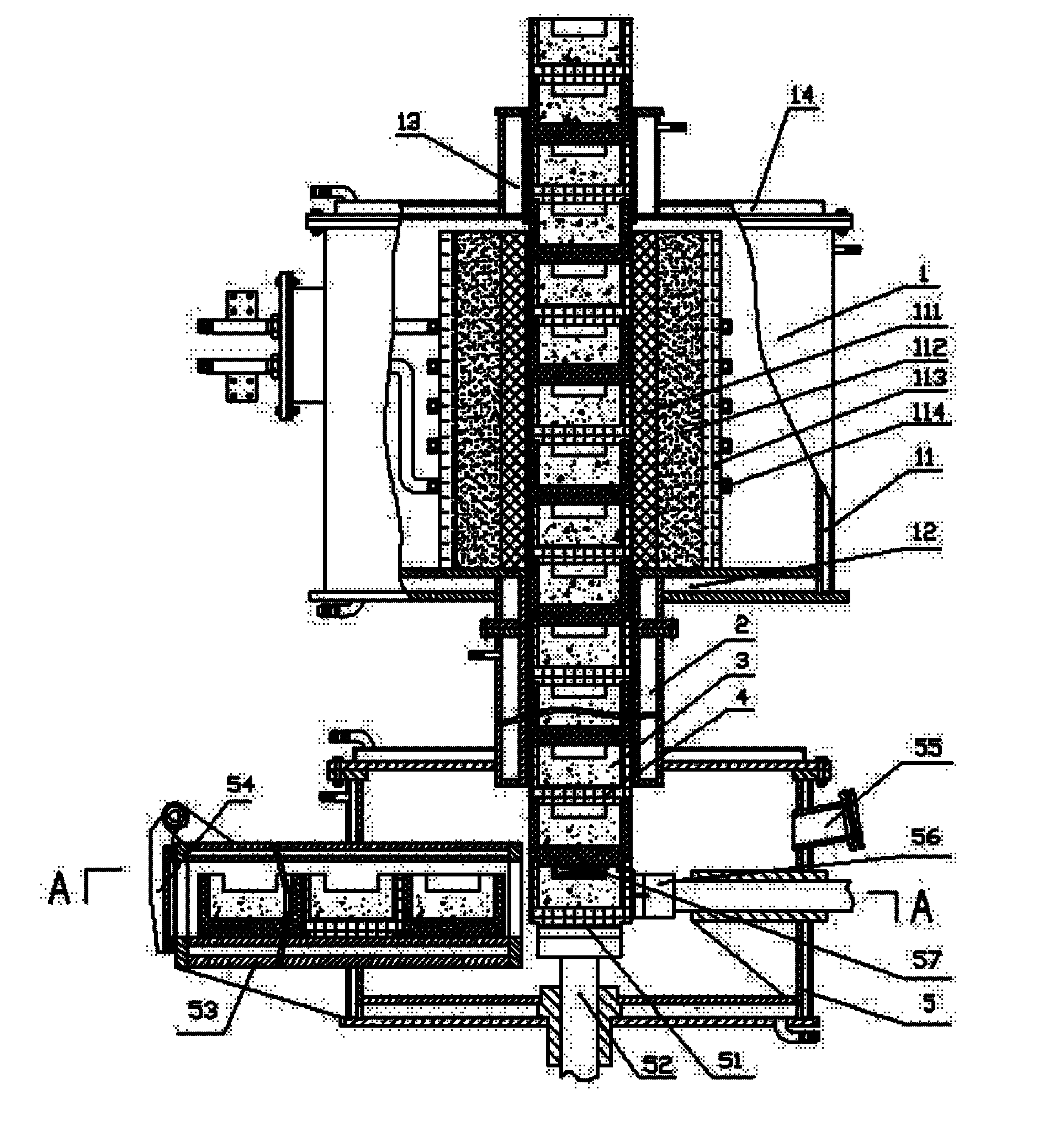

[0025] see figure 1 and figure 2 , an induction heating ultra-high temperature continuous carbonization furnace, comprising a furnace body, a boat 4, a furnace bottom 12, a furnace nozzle 13, a furnace cover 14, an insulation layer, a furnace door 54, a heating element 111, and an induction coil 114, characterized in that:

[0026] This induction heating ultra-high temperature continuous carbonization furnace includes a vertical channel and a horizontal channel formed by three parts: the upper furnace body 1, the middle water-cooled connecting sleeve 2 and the lower furnace body 5. The upper furnace body 1 and the lower furnace body 5 pass through The middle water-cooling connection sleeve 2 is connected;

[0027] The upper furnace body 1 is mainly responsible for heating and other tasks. The upper furnace body 1 includes a heating element 111, an inner insulation layer 112, an outer insulation layer 113, an induction coil 114 for internal cooling water, a sandwich furnace c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com