On-line monitoring device and method of stress intensity of pressure-containing member outside station boiler

A technology for power station boilers and pressure-bearing parts, which is applied in the direction of electrical program control, program control, and control system, can solve the stress intensity change of the pressure-bearing parts outside the power station boiler furnace, shorten the service life of the pressure-bearing parts outside the power station boiler furnace, and cannot. Realize the monitoring and control of the stress intensity of the external pressure-bearing parts of the boiler in the power station, so as to reduce the stress intensity and ensure the long-term safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

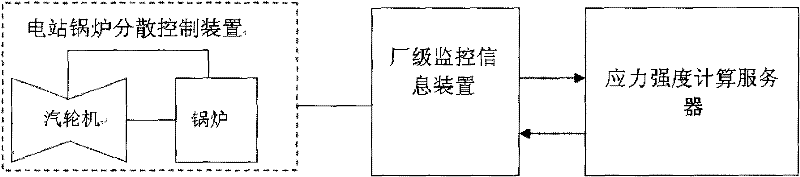

[0047] Such as figure 1 As shown, it is a block diagram of the online monitoring device for the stress intensity of the pressure-bearing parts outside the power plant boiler furnace of the present invention. The composition of the control device. The stress intensity calculation server is connected with the distributed control device of the utility boiler through the plant-level monitoring information device.

[0048] Such as figure 2 As shown, it is a flow chart of the online monitoring method for the stress intensity of the pressure-bearing parts outside the power station boiler furnace of the present invention, as image 3 As shown, it is a block diagram of the computer software adopted by the calculation server of the present invention. The software is installed on the stress intensity calculation server and is applied to the online calculation and control of the stress intensity of the external pressure-bearing parts of the power plant boiler.

[0049] For a certain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com