Lock chamber energy dissipating open ditch of ship lock

A lock chamber and open ditch technology, applied in ship locks, ship lifting devices, buildings, etc., can solve the problems of limited application scope of energy dissipation in single open ditch, complicated layout of water delivery systems in lock chambers, unfavorable water flow diffusion and energy dissipation, etc. The effect of reducing the number of sluice chamber corridors, reducing the local water surface height, and improving the energy dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

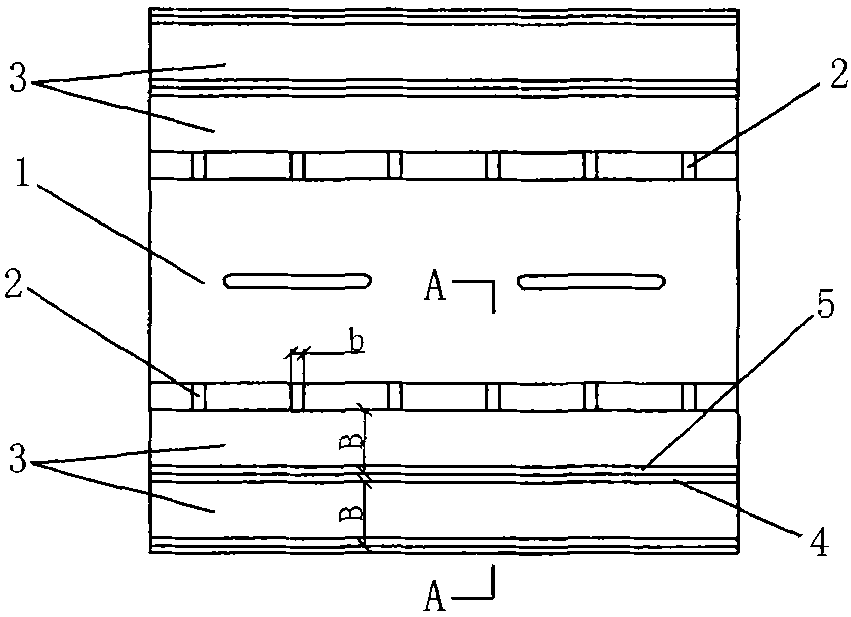

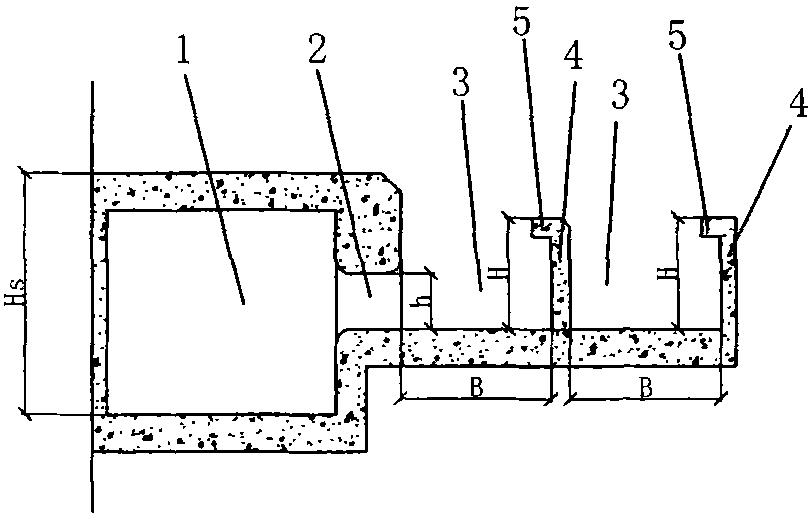

[0025] The energy-dissipating open ditch of the lock chamber of the present embodiment, such as figure 1 and figure 2 As shown, it includes the lock chamber adopting the distributed water delivery system of the side branch holes of the longitudinal corridor at the bottom of the lock chamber (only a section of the lock chamber is reflected in the figure), and the lock chamber corridor 1 is arranged along the longitudinal length of the lock chamber, and the lock chamber corridor 1 The bottoms of both sides are provided with side outlet branch holes 2 arranged at intervals, and an open ditch 3 surrounded by stilling sills 4 spaced apart from each other is provided outside the outlet branch hole 2, wherein the open ditch 3 on the side of the outlet branch hole 2 has Second way. Two open ditches 3 are arranged along the longitudinal length of the sluice chamber, and a horizontal baffle 5 protruding toward the water outlet branch hole 2 is arranged on the top of the stilling sill ...

Embodiment 2

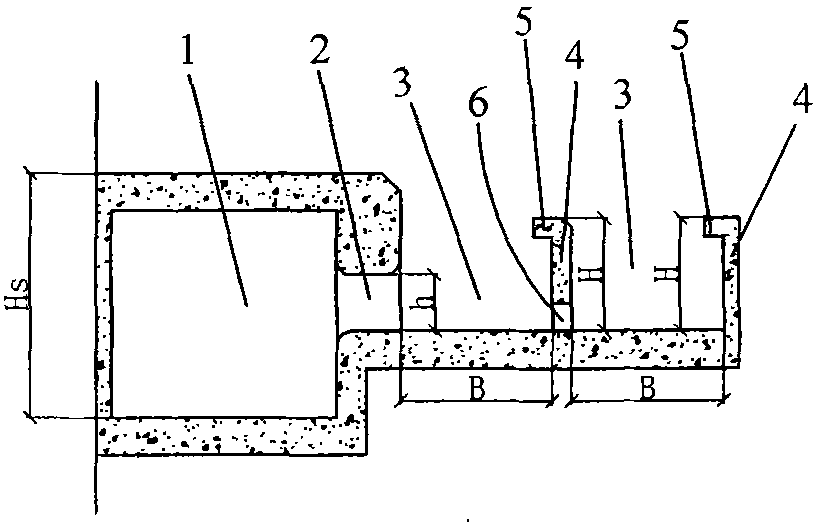

[0028] The energy-dissipating open ditch in the lock chamber of this embodiment is as follows: image 3 As shown, it is basically the same structure as the energy-dissipating open ditch of the ship lock chamber in Embodiment 1, the difference is that water permeable holes 6 arranged at intervals are arranged in the middle of the stilling sill 4 .

Embodiment 3

[0030] The energy-dissipating open ditch in the lock chamber of the present embodiment is an improvement on the basis of Embodiment 1, as Figure 4 and Figure 5 As shown, the difference except that it is the same as that of Embodiment 1 is: 1) the lock chamber adopts a decentralized water delivery system of the longitudinal main corridor of the gate wall and the horizontal branch corridor at the bottom of the gate, and the transverse branch corridor is the lock chamber corridor 1 , the main corridor 101 is located in the gate walls 100 on both sides, the main corridor 101 is connected with the lock chamber corridor 1 (horizontal branch corridor), and the lock chamber corridor 1 (horizontal branch corridor) is located at the bottom of the lock chamber and along the gate The chambers are horizontally arranged in a staggered conical shape; 2) The upper side and the side of the outlet of the outlet branch hole 2 are respectively provided with a shroud 7 and a diversion pier 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com