A sample loading device for pipeline erosion corrosion test

A loading device and scouring corrosion technology, which is used in measuring devices, testing wear resistance, instruments, etc., can solve the problems of difficult sample orientation and position positioning, complicated sample loading procedures, and disordered pipeline flow rate, etc., to improve the sample. Inaccurate quantitative test, simple structure, reducing the effect of water turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

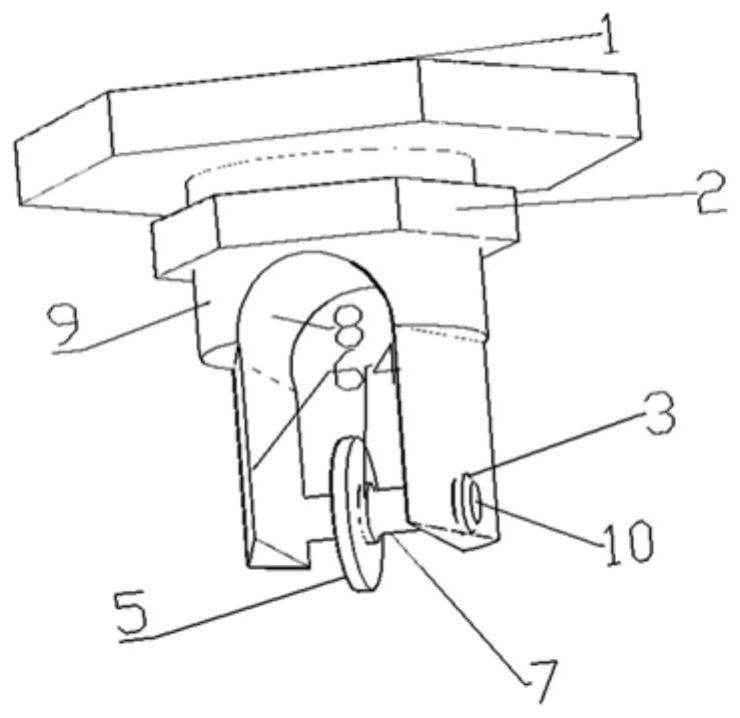

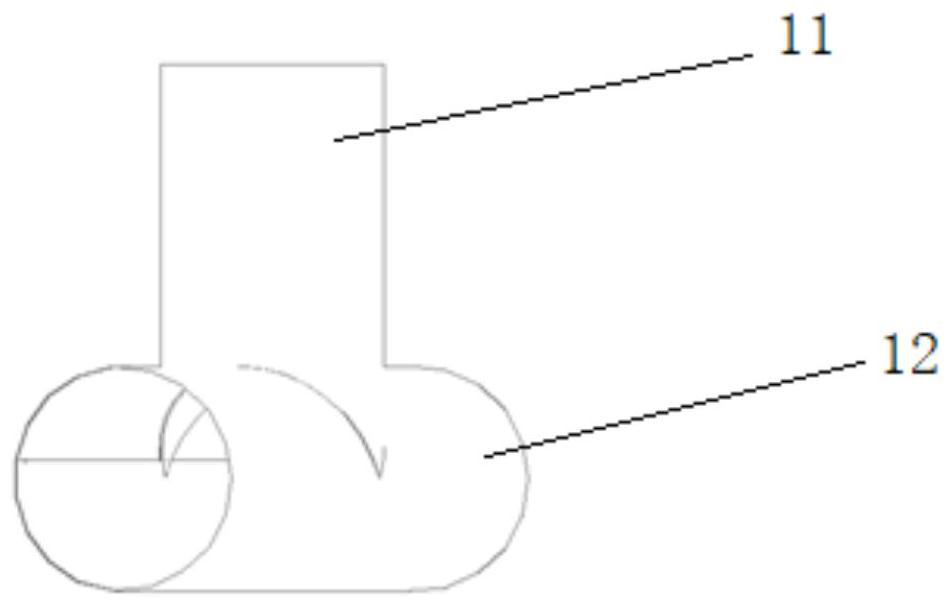

[0045] use as figure 1 , 2 As shown in the pipeline erosion corrosion test device, the sample loading rod is inserted into the loading hole of the blade-shaped structure at the through-slot bifurcation, and then passes through the inner tightening nut, the sample and the inner tightening nut in sequence, and the sample is fixed in the test. The sample loading rod is in the middle. Then fix the sample loading rod on the main screw through the outer tightening nut. The sample loading device that completes the sample fixation is screwed into the access port of the sample loading device of the fluid pipeline of the pipeline erosion corrosion test device. After screwing in, the orientation of the sample is adjusted according to the orientation of the top of the main screw to meet the test requirements. .

[0046] After the sample loading device is screwed into the pipeline, it is determined that the direction of the sample is at an angle of 180° to the direction of the water flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com