Design method of low-noise cut-off tube for valve tower cooling system of UHV converter station

A cooling system and design method technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as high operating noise, adverse effects on physical and mental health of operating personnel, and impact on cooling water cooling effect, etc., to reduce the noise level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

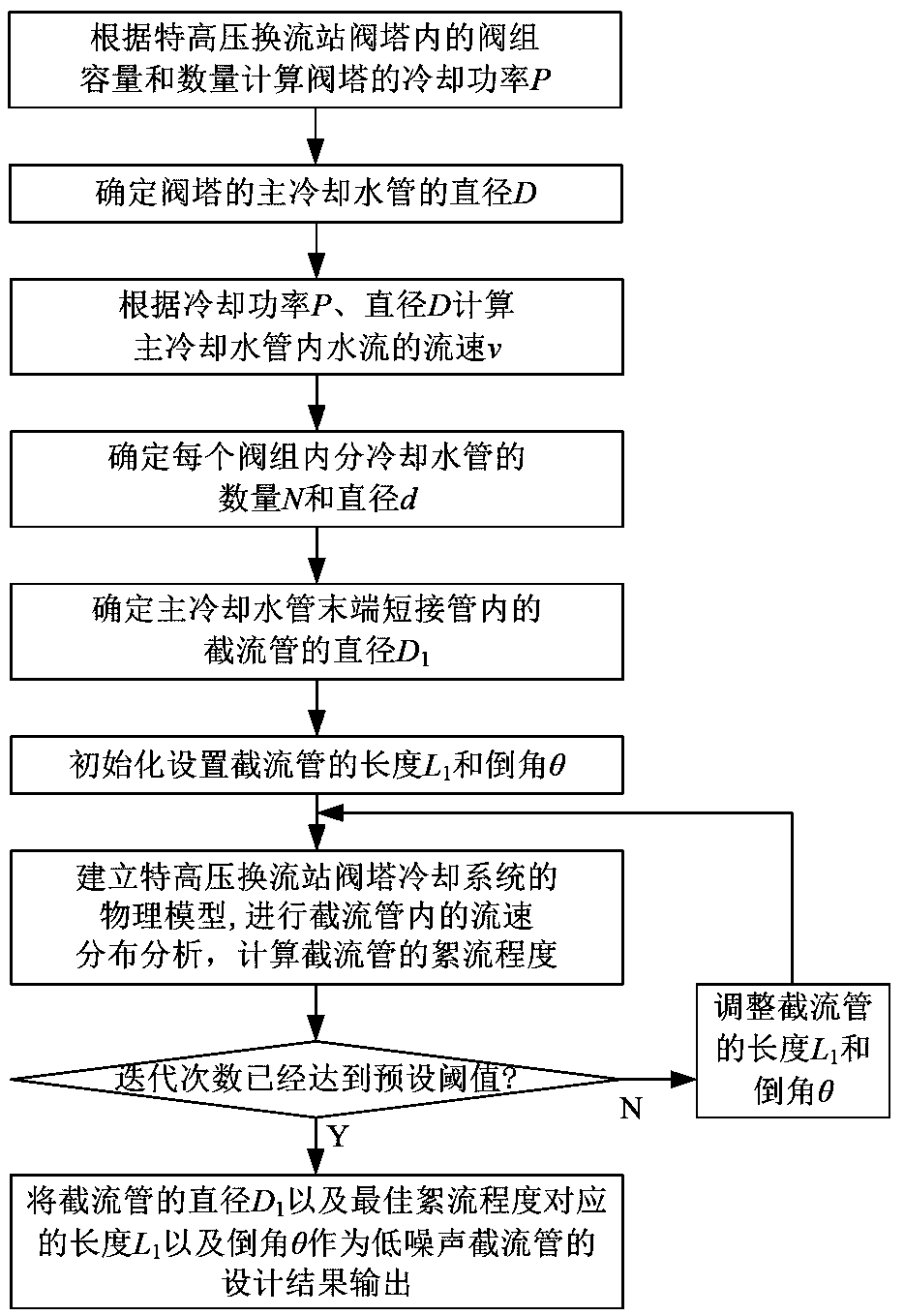

[0036] Such as image 3 As shown, the implementation steps of the low-noise interceptor design method of the present embodiment include:

[0037] 1) Calculate the cooling power of the valve tower according to the capacity and quantity of the valve group in the valve tower of the UHV converter station P ;

[0038] 2) Determine the diameter of the main cooling water pipe of the valve tower D ;

[0039] 3) According to the cooling power P ,diameter D Calculation of the flow velocity of the water flow in the main cooling water pipe v ;

[0040] 4) Determine the number of cooling water pipes in each valve group N and diameter d ;

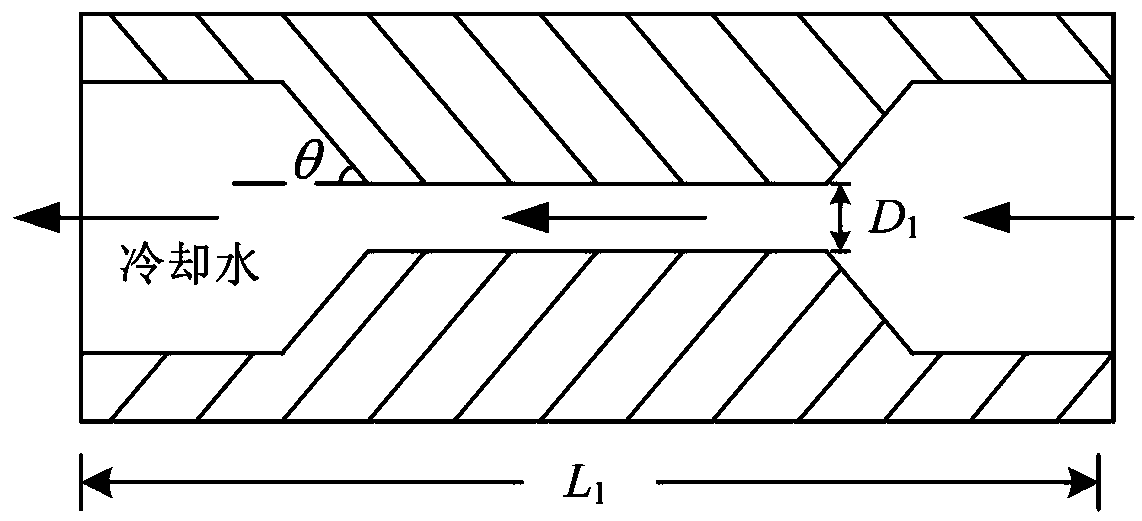

[0041] 5) Determine the diameter of the cut-off pipe in the short connection pipe at the end of the main cooling water pipe D 1 ;

[0042] 6) Initialize the length of the interceptor L 1 and chamfer θ ;

[0043] 7) According to the diameter of the main cooling water pipe D , The number of cooling water pipes in each valve group N and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com