Coal bed gas produced water deep treatment equipment

A technology for advanced treatment and production of water, applied in mining wastewater treatment, energy wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problem of large heat sources in the evaporation pond method, achieve high automation, improve efficiency, and increase temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

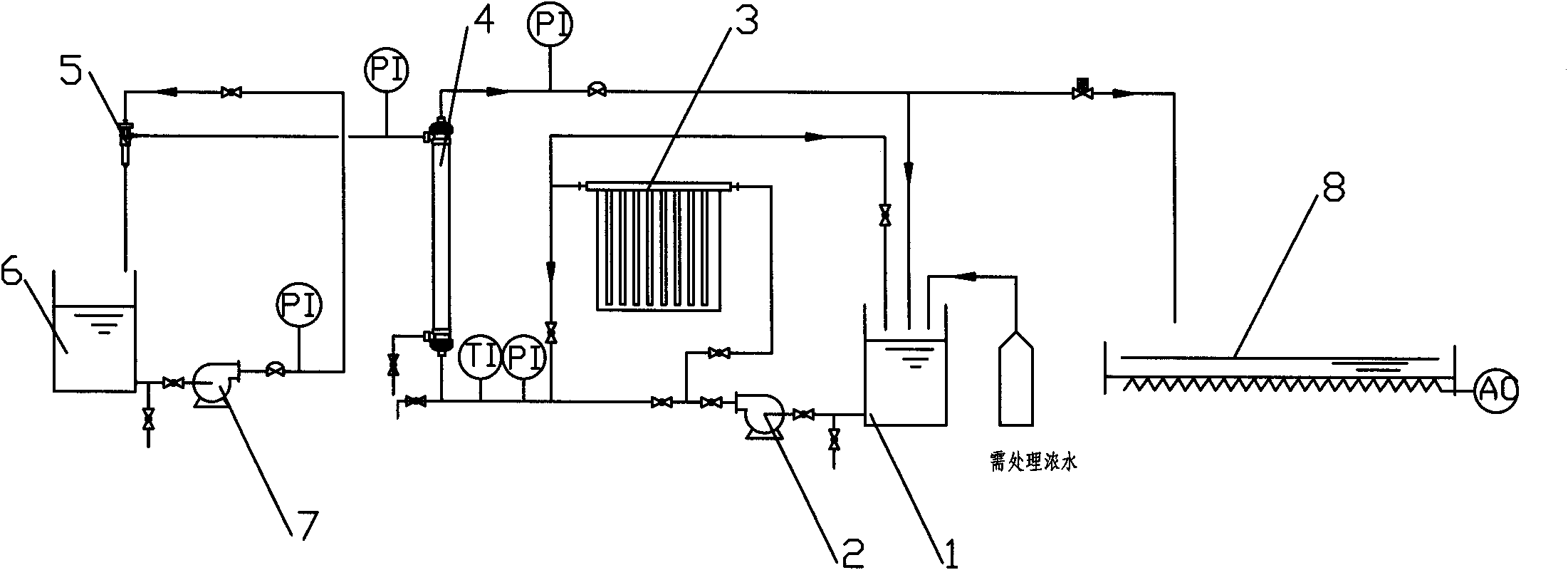

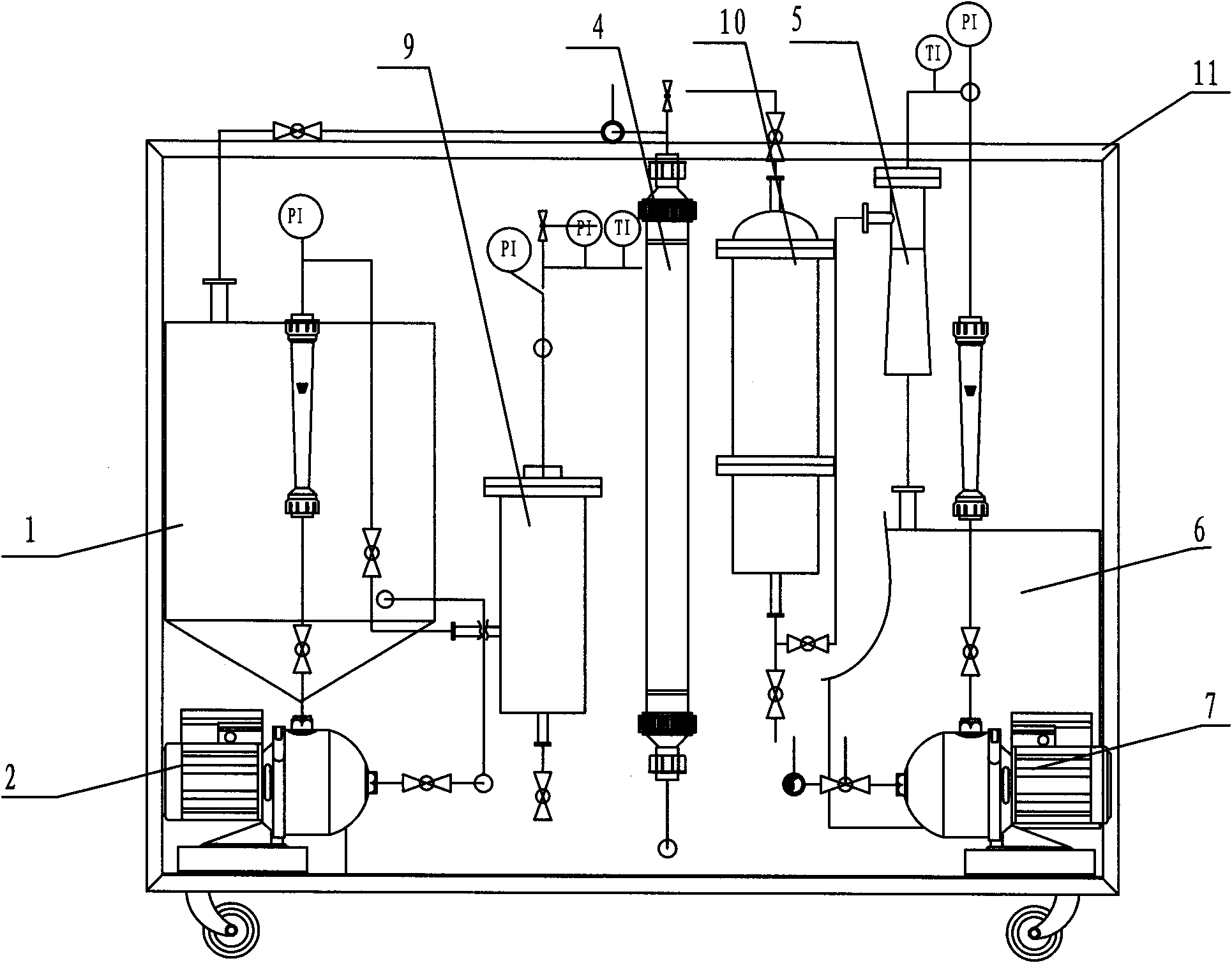

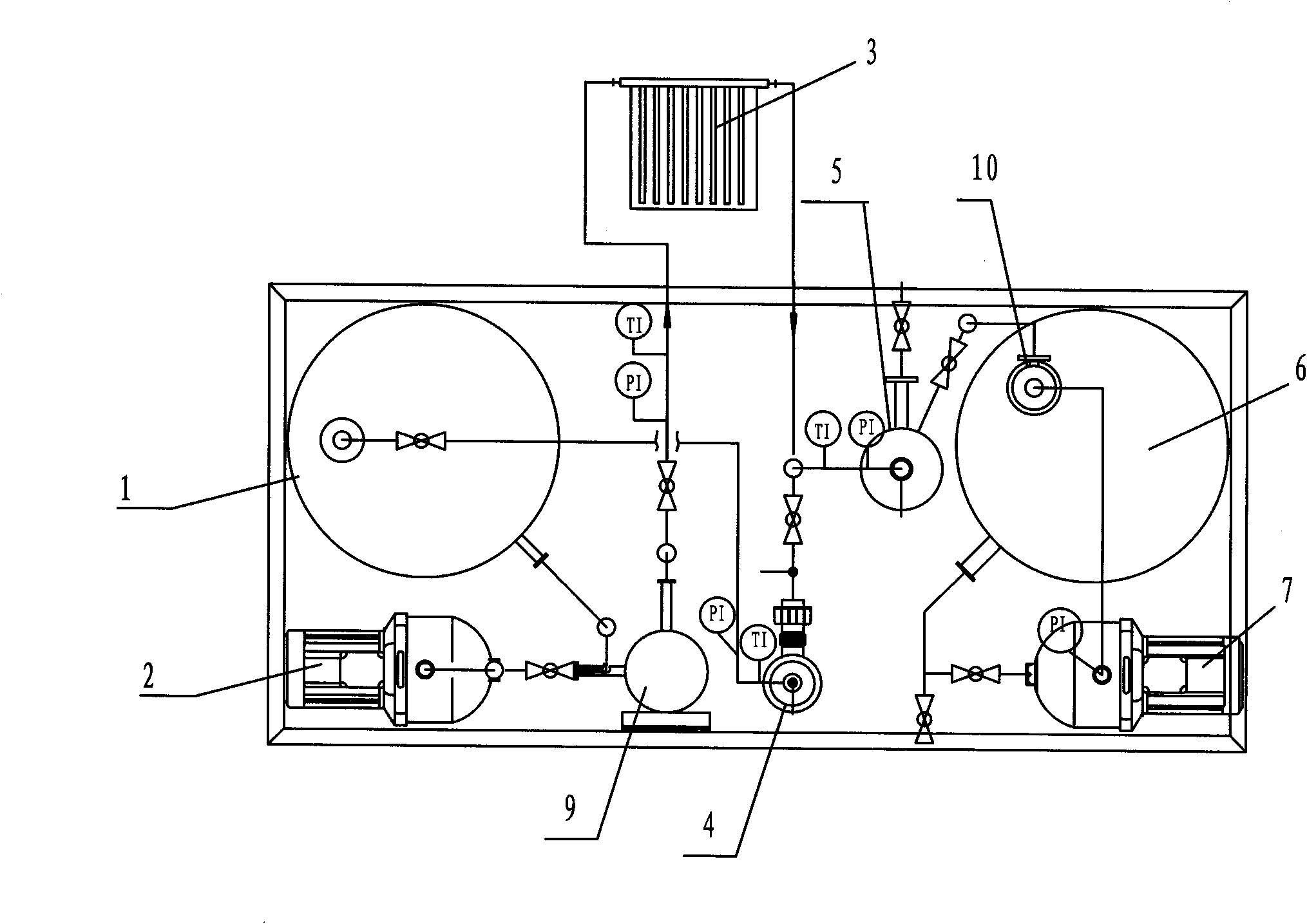

[0024] Such as figure 1 As shown, the concentrated water after reverse osmosis or electrodialysis treatment and the chemical regeneration and flushing wastewater after ion exchange resin treatment contain very high concentrations of minerals. The concentrated water or flushing wastewater enters the raw water pool 1, and the The concentrated water or flushing wastewater enters the solar heat collector 3 after being boosted by the raw water pump 2; the concentrated water or flushing wastewater enters the raw water side of the hydrophobic membrane module 4 after being heated. Due to the high temperature of concentrated water or flushing wastewater, and the positive pressure on the raw water side, the water vapor partial pressure on the raw water side is greater than the water vapor pressure on the fresh water side of the hydrophobic membrane, so the water vapor on the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com