Anti-micro pitting gear oil composite additive

A compound additive and anti-micropitting technology, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems of not having anti-micropitting corrosion, and achieve the effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 214.5 kg of 500SN base oil to a blending kettle with a stirrer, stir and heat up to 115°C, add 70 kg of phenyl-1-naphthylamine, and wait until the phenyl-1-naphthylamine is completely dissolved, then stir at a constant temperature Add 450 kg of oleic acid-modified potassium monoborate with a particle size of 55 nm, 250 kg of BT154, 0.5 kg of T901, and 15 kg of DL-32. After the addition is complete, stir at a constant temperature of 100°C for 1 hour, cool to below 60°C, filter and package the finished product.

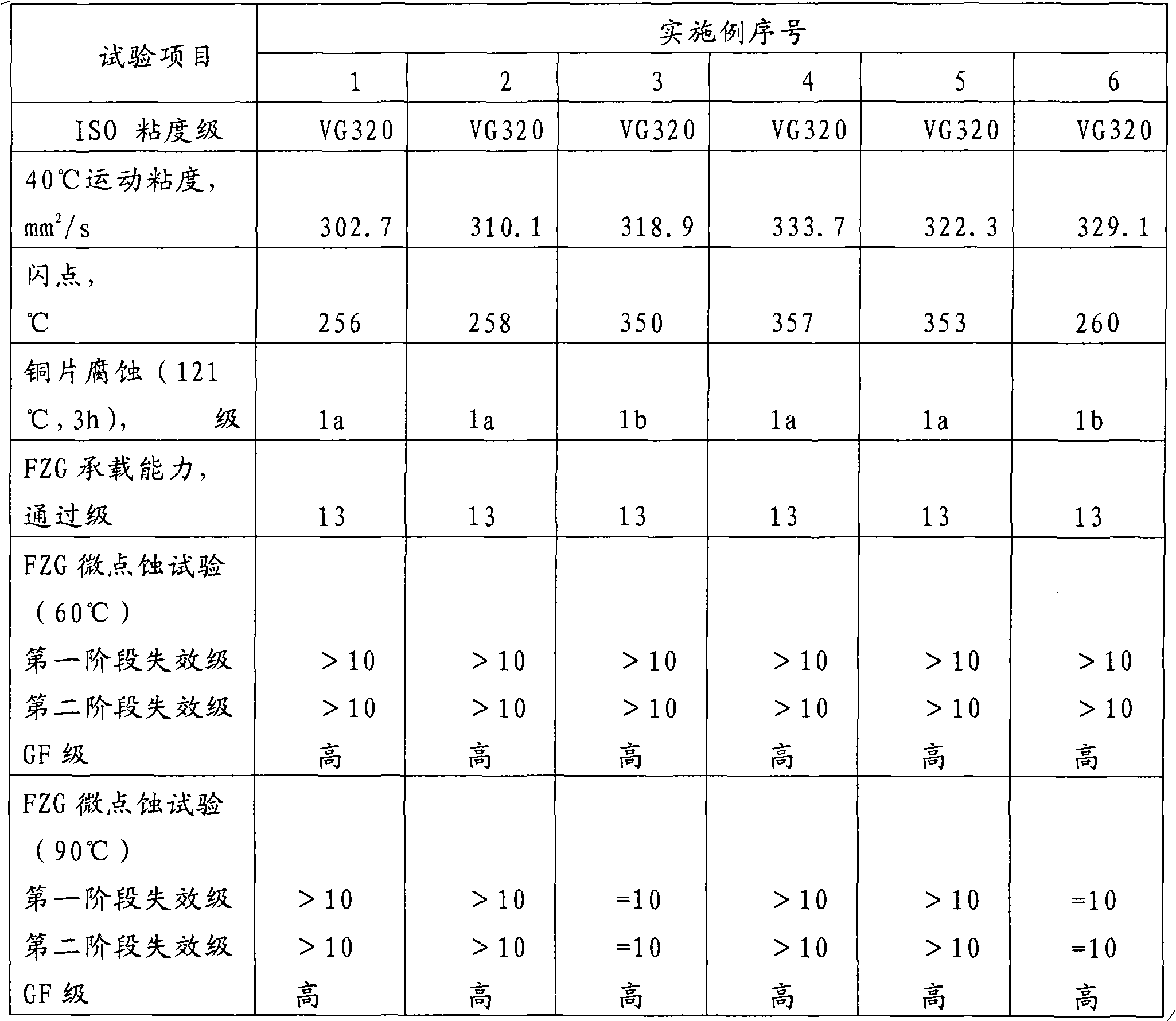

[0024] The performance of the ISO VG320 industrial gear oil made of the anti-micropitting gear oil compound additive 2.5% and ISO VG320 base oil prepared in this example is shown in the serial number 1 in the attached table 1.

Embodiment 2

[0026] In a mixing kettle with a stirrer, add 214.5 kg of 500SN base oil, stir and heat up to 115°C, add 35 kg of phenyl-1-naphthylamine, 35 kg of 2,6-di-tert-butyl p-cresol, wait After phenyl-1-naphthylamine and 2,6-di-tert-butyl-p-cresol are completely dissolved, add 450 kg of oleic acid-modified potassium monoborate with a particle size of 92nm, 250 kg of BT154, and 0.5 kg of MS-5A, 15 kg DL-32. After the addition is complete, stir at a constant temperature of 100°C for 1 hour, cool to below 60°C, filter and package the finished product.

[0027] The performance of the ISO VG320 industrial gear oil prepared with the anti-micropitting gear oil compound additive 2.5% and ISO VG320 base oil in this embodiment is shown in the serial number 2 in the attached table 1.

Embodiment 3

[0029] Add 222.7 kg of 500SN base oil to a blending kettle with a stirrer, stir and heat up to 115°C, add 60 kg of phenyl-1-naphthylamine, and wait until the phenyl-1-naphthylamine is completely dissolved, then stir at a constant temperature Add 470 kg of oleic acid-modified potassium metaborate with a particle size of 92 nm, 230 kg of BT154, 0.3 kg of T901, and 17 kg of DL-32. After the addition is complete, stir at a constant temperature of 100°C for 1 hour, cool to below 60°C, filter and package the finished product.

[0030] The performance of the ISO VG320 industrial gear oil prepared with 2.5% of the anti-micropitting gear oil composite additive prepared in this example and ISO VG320 base oil is shown in the serial number 3 in the attached table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com