Laser parameter integrated test system

A technology for comprehensive testing and laser parameters, applied in the field of comprehensive testing systems for laser parameters, it can solve problems such as increasing complexity, and achieve the effects of small spherical aberration and astigmatism, real-time measurement, and high equipment integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

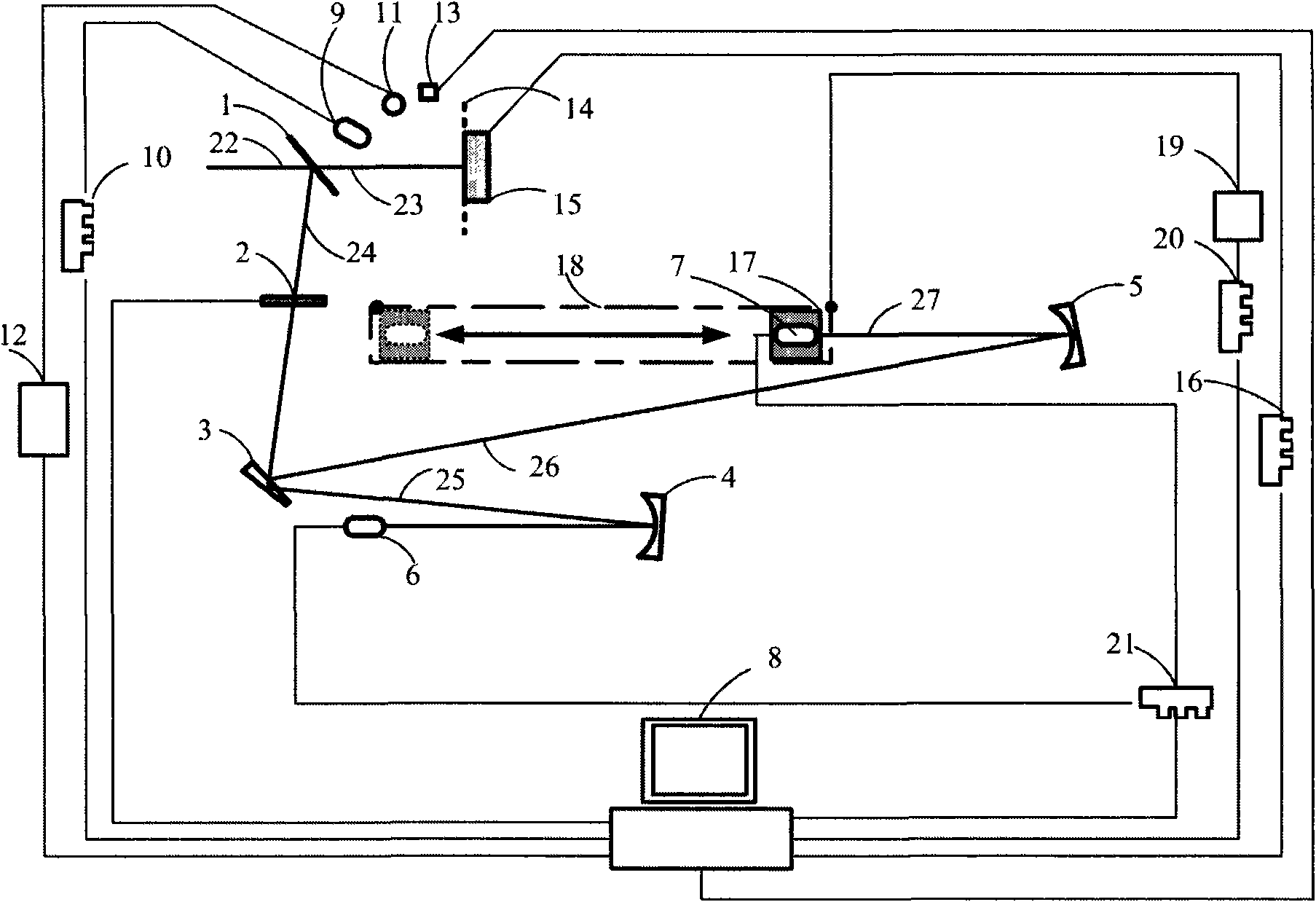

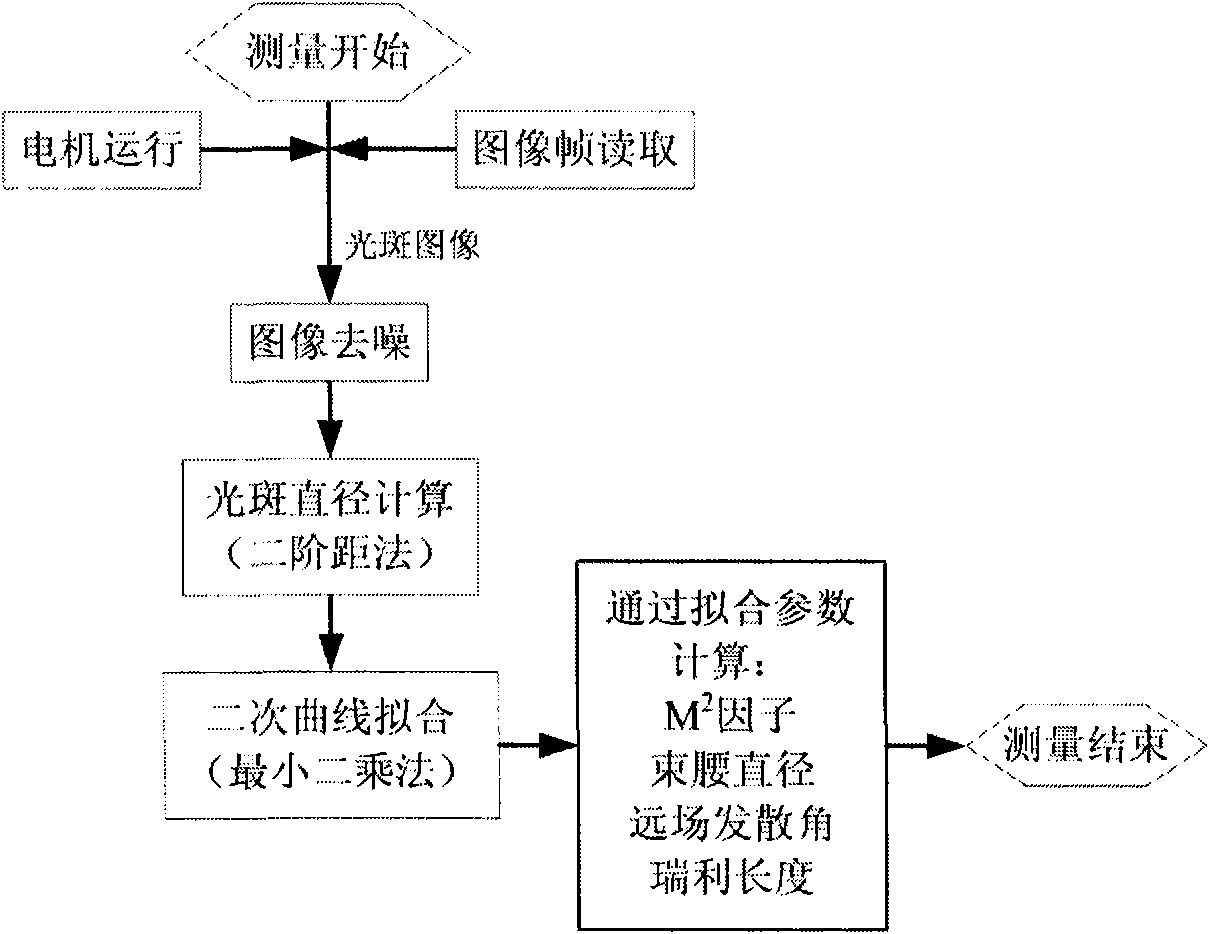

[0072] The plane mirror 1 has a wedge angle of 5° to prevent the reflected light from the rear surface of the plane mirror 1 from entering the test light path, and because the transmitted light is used, the mirror is not coated. The wedge angle of the wedge beamsplitter 3 is 3° and is not coated. The short focal length concave spherical mirror 4 and the long focal length concave spherical mirror 5 are coated with 99.9% high reflection film. The focal length of short focal length concave spherical reflector 4 is selected as 250mm (radius of curvature 500mm), and the focal length of long focal length concave spherical reflector 5 is selected as 1000mm (radius of curvature 2000mm), and the off-axis angle of long focal length concave spherical reflector (5) is 2°, the shortest distance from the second digital area array CCD camera 7 to the long focal length concave spherical mirror 5 is 850mm. Stepper motor 18 drives the second digital area array CCD camera 7 before the spot imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com