Preparation method of nuclear shell structure high-silicon silicone acrylic emulsion used for building exterior wall

A core-shell structure, silicone-acrylic emulsion technology, applied in the field of building materials, can solve the problems of failing to meet the characteristic requirements of silicone resin, low content of silicone components, serious tendency of hydrolysis and self-polymerization, etc., and achieves excellent weather resistance, The polymerization system is stable and the effect is conducive to storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, preparation unsaturated organosiloxane oligomer emulsion

[0034] First add 10kg sodium dodecylbenzene sulfonate, 6kg OP-10, 80kg deionized water into the reaction kettle, stir for 5 minutes; then add 20kg octavinylcyclotetrasiloxane, 20kg octamethylcyclotetrasiloxane Siloxane, 10kg dodecylbenzenesulfonic acid, stirred for 10 minutes. Afterwards, the temperature was raised to 50-55° C., and the reaction was kept for 3 hours. Then add 5kg of dodecylbenzenesulfonic acid, stir evenly and heat up to 65-70°C, keep warm for 3 hours; finally add 5kg of dodecylbenzenesulfonic acid and cool down to room temperature, stir and react for 25 hours. Obtain unsaturated organosiloxane oligomer emulsion.

[0035] The solid content of the obtained emulsion is 25-35%, the molecular weight is 500-1000, and the storage stability is greater than 2 months.

Embodiment 2

[0036] Embodiment 2, nuclear emulsion synthesis

[0037] Take 3 parts of methyl methacrylate and 2 parts of butyl acrylate by mass, and mix them uniformly to obtain a mixture of acrylate monomers.

[0038]Add 4.5kg of sodium lauryl sulfate, OP-103kg, and 100kg of deionized water into the reactor, and stir evenly; add 40kg of the unsaturated organosiloxane oligomer emulsion prepared in the examples, and the acrylate monomer mixture 15kg, stirred for 30 minutes; then added 1kg of potassium persulfate, 0.67kg of sodium bisulfite, and 0.5kg of sodium bicarbonate, mixed evenly, and then heated up to 65°C. 1kg of alkyl mercaptan, and 35kg of acrylate monomer mixture, 2kg of potassium persulfate and 1.33kg of sodium bisulfite were added dropwise at the same time, and the time for the dropwise addition was 1 hour. Get nuclear emulsion.

Embodiment 3

[0039] Example 3 Core-shell emulsion synthesis

[0040] Get the nuclear emulsion 60kg that embodiment 2 makes, deionized water 50kg, sodium lauryl sulfate 1.2kg, OP-10 0.8kg, the acrylate monomer mixture 40kg that prepares in embodiment 2, vinyl triethoxylate 2 kg of silane and 0.4 kg of potassium persulfate were sequentially added into the reaction kettle, mixed uniformly, heated to 85° C., and reacted at constant temperature for 3 hours. Silicone acrylic core-shell emulsion was obtained.

[0041] The main performance indicators of the obtained silicone acrylic emulsion are as follows:

[0042] Table 1 Silicone acrylic emulsion comprehensive performance index

[0043]

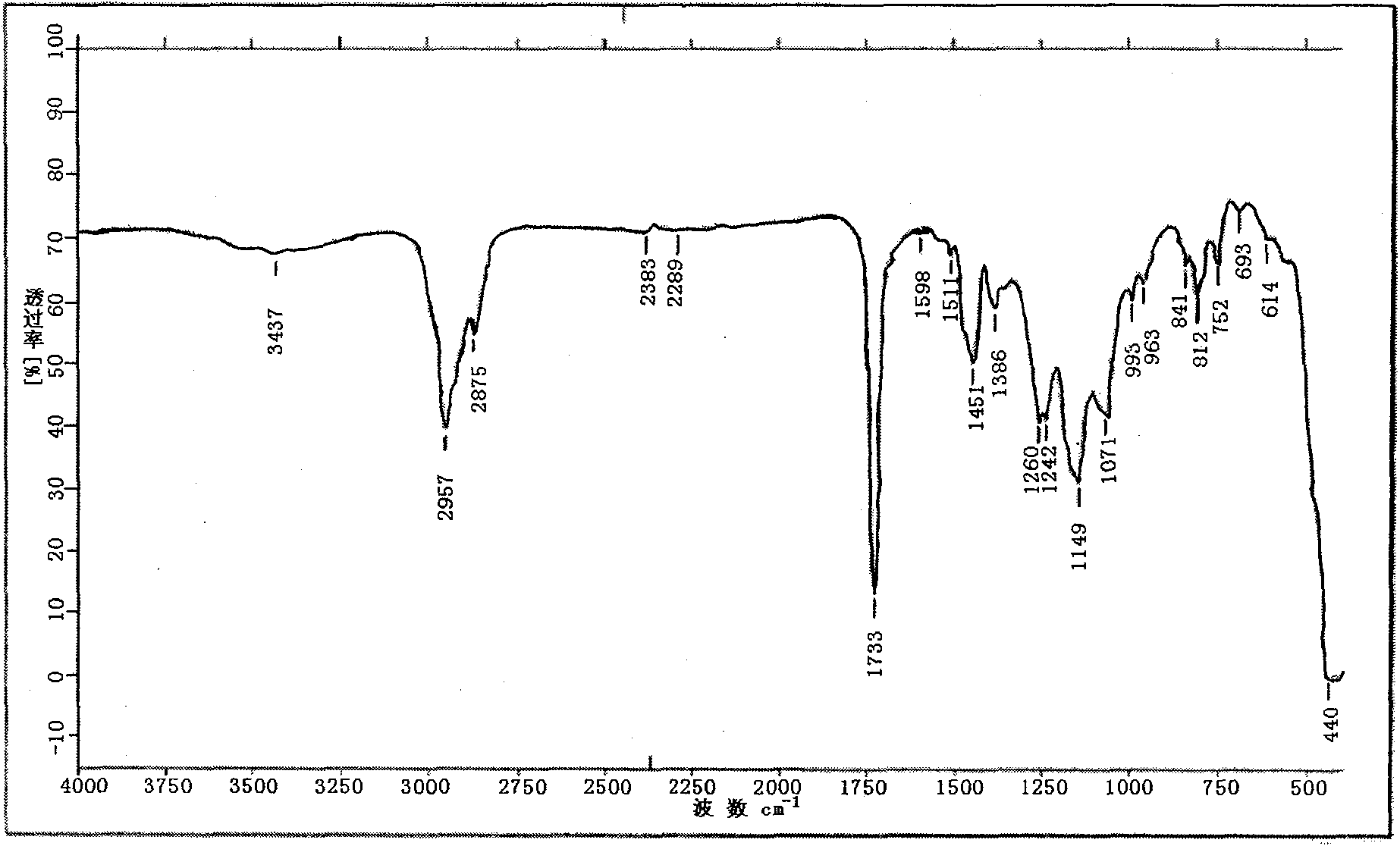

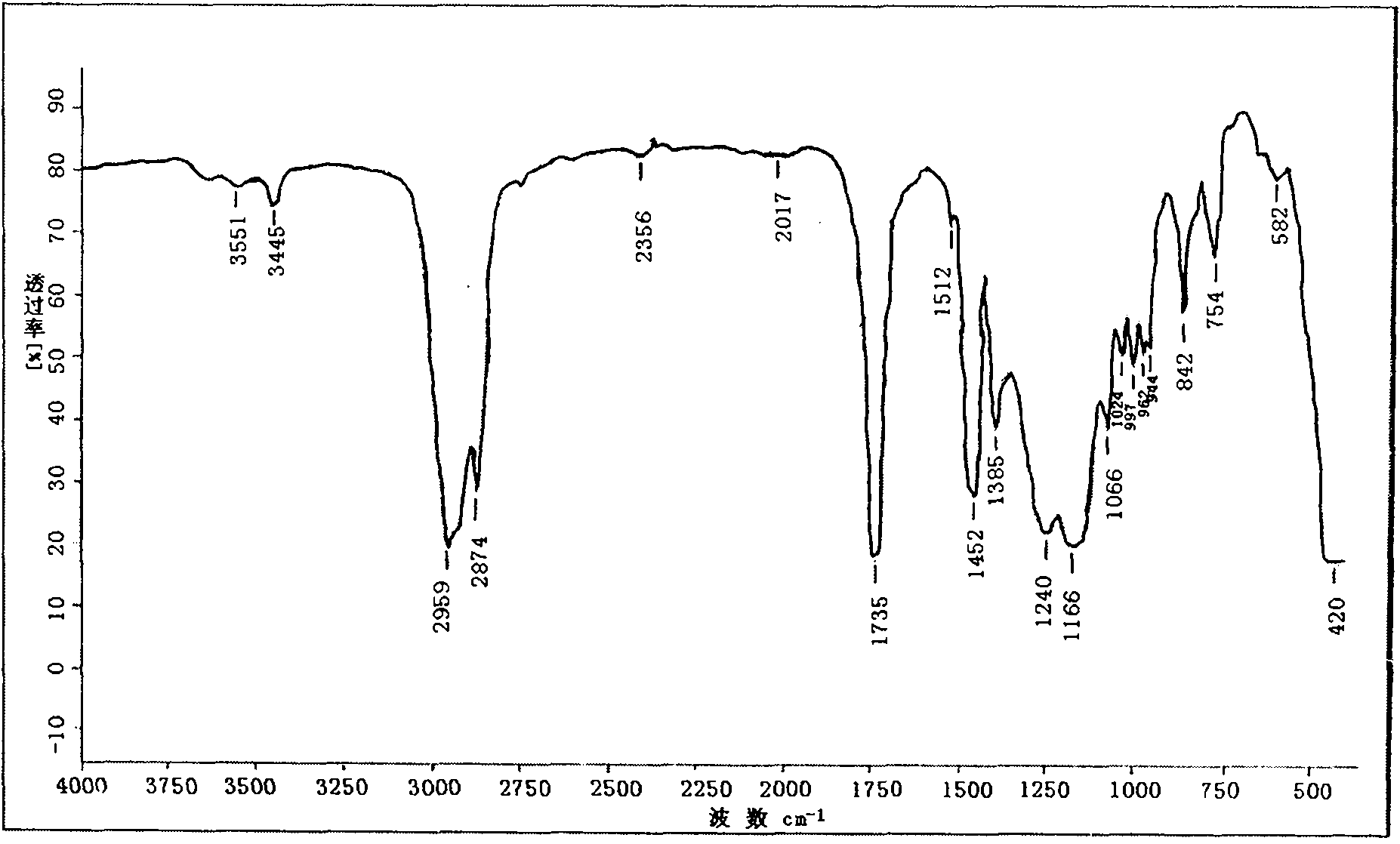

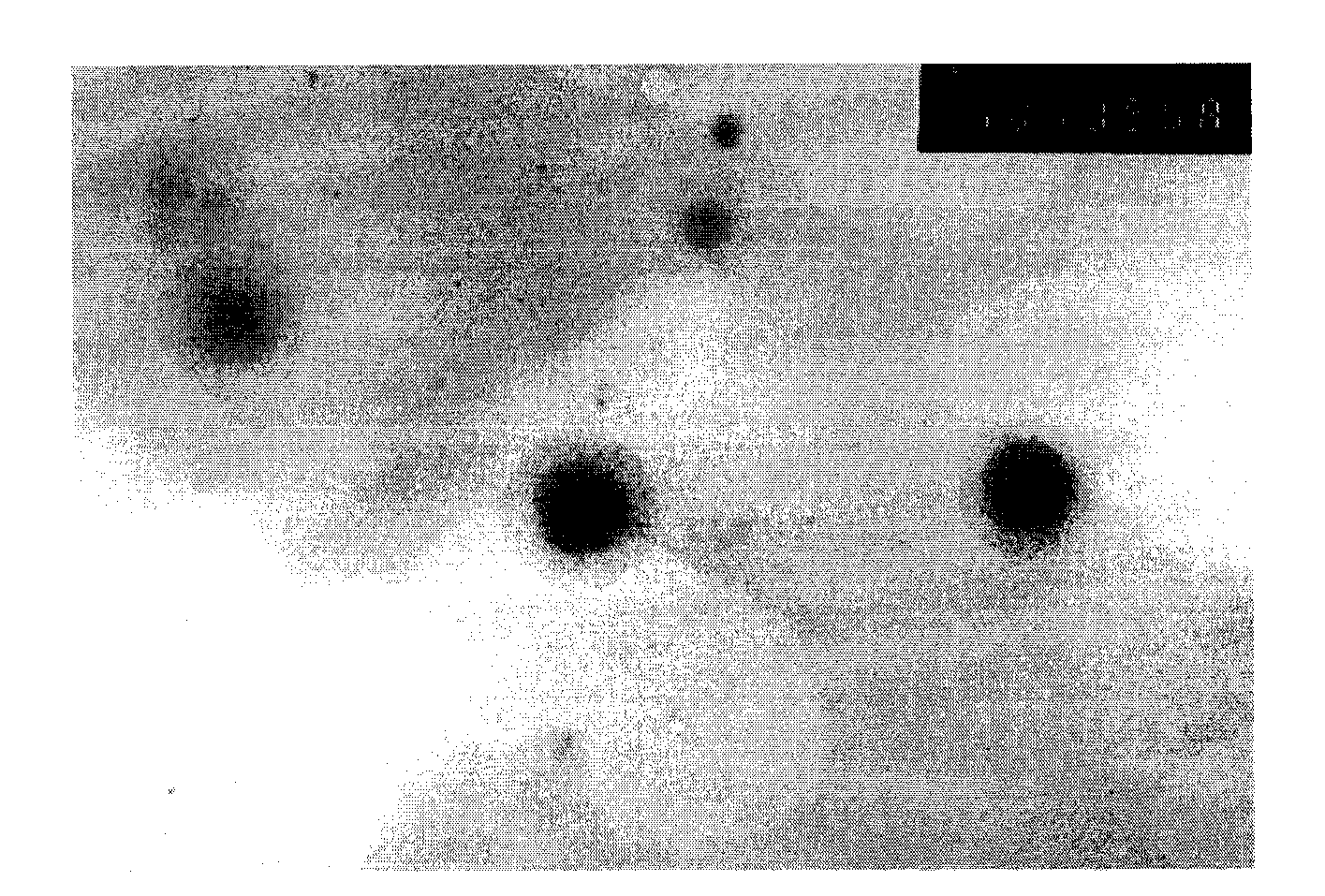

[0044] The core-shell silicon-acrylic emulsion prepared by the present invention realizes organic silicon chemically modified acrylate emulsion through the addition and copolymerization of unsaturated organosiloxane oligomers and acrylates. figure 1 , 2 illustrates this result; image 3 And attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com