Drive axle shaft clutch

A clutch and drive axle technology, applied in clutches, control devices, mechanical equipment, etc., can solve the problems of inability to cut off torque, dragging and energy consumption of ineffective linkages, so as to reduce mechanical energy loss and extend light-load gliding distance. , Significant fuel-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

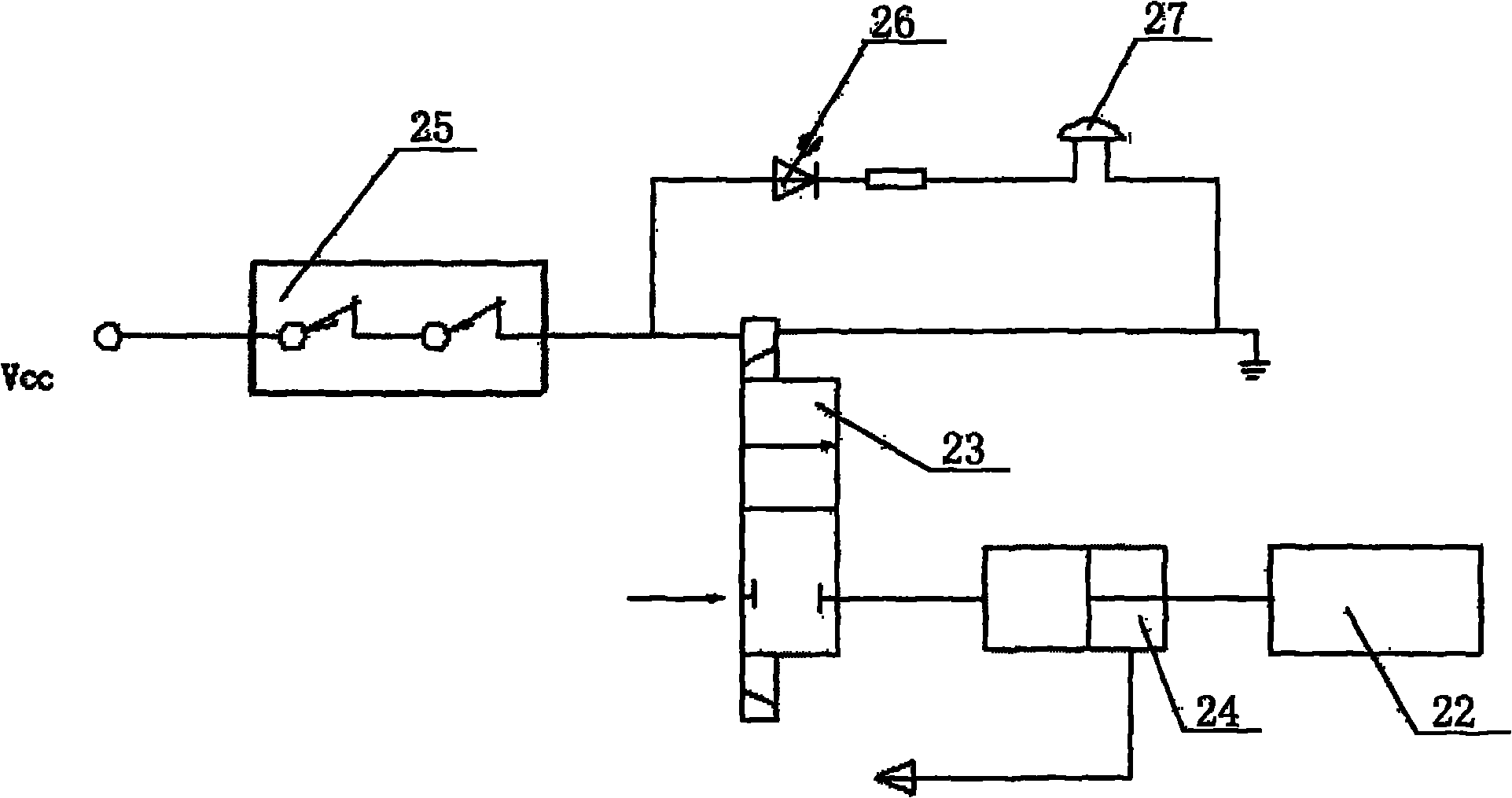

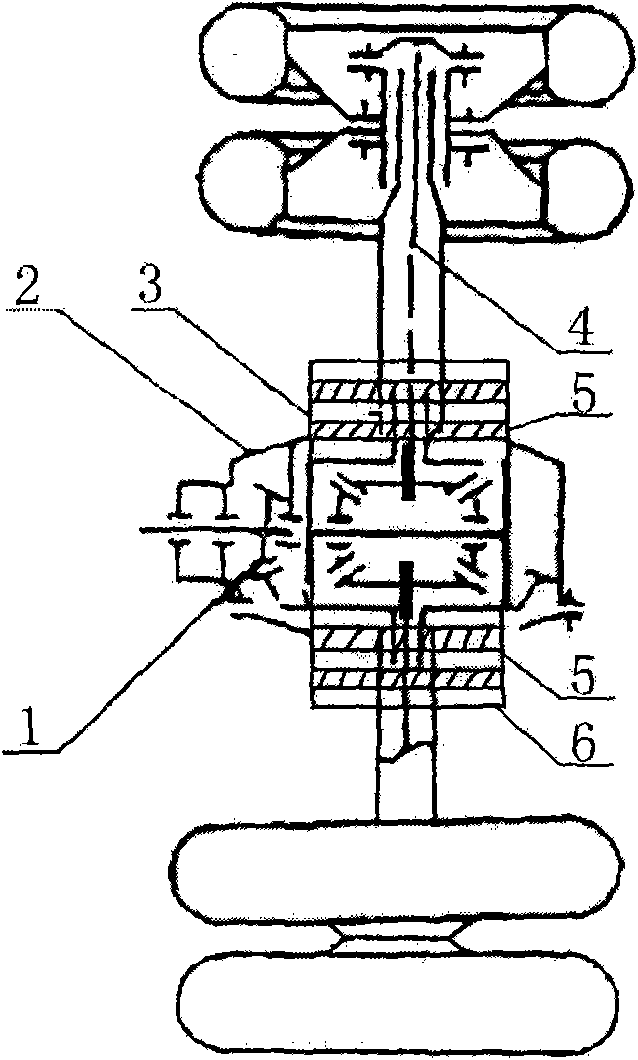

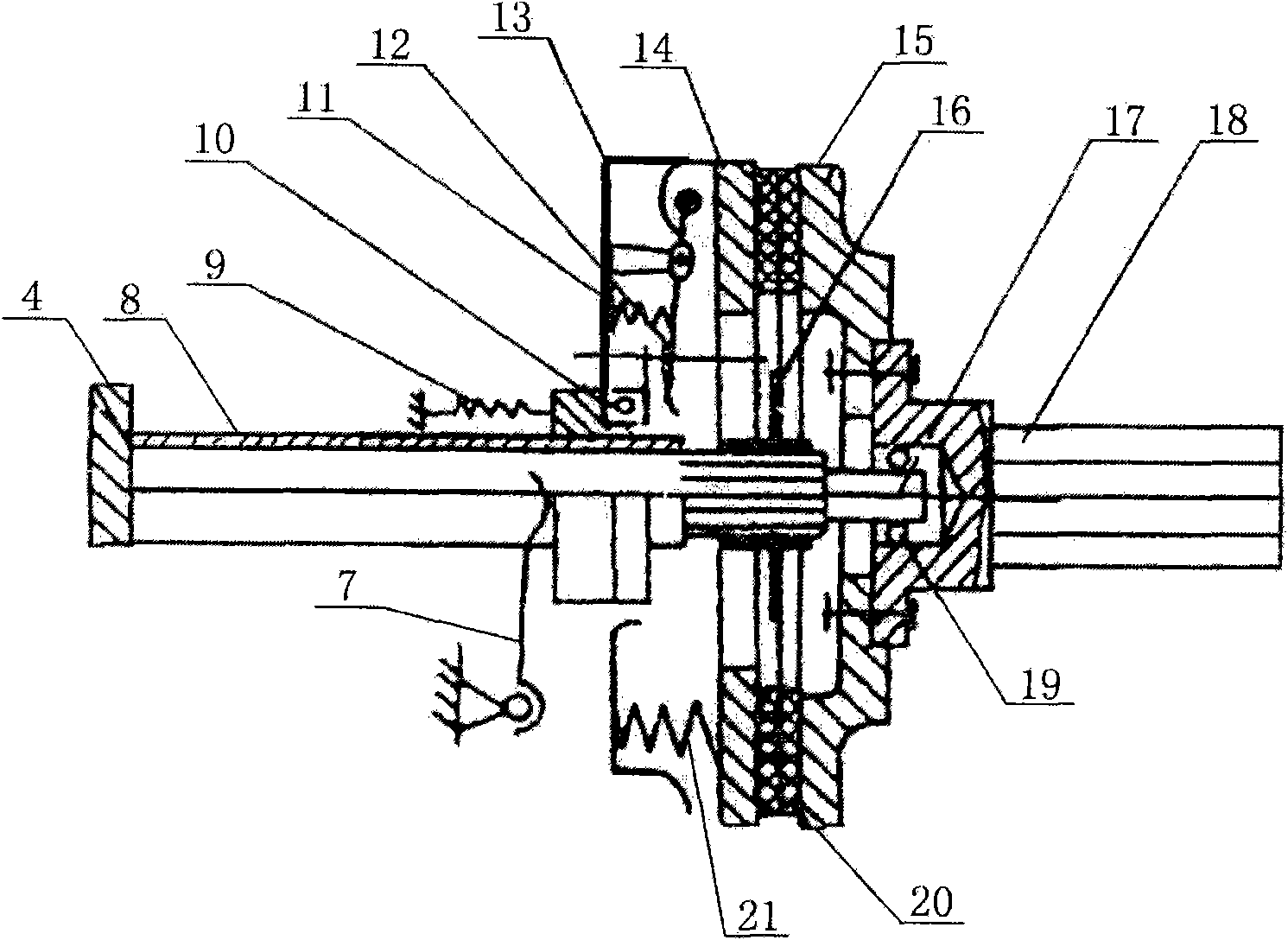

[0018] see figure 1 , including the axle shaft of the drive axle, on which the half axle clutch is arranged, the installation inspection hole for the clutch and the differential is arranged on the axle casing of the axle axle, the release lever 22 of the axle clutch is connected with the air valve 23 and the air storage tank 24 respectively Connection, between the air valve 23 and the brake mechanism, an alarm circuit composed of light-emitting diodes 26 and buzzer 27 is connected. When the car is running, when the driver's foot leaves the accelerator pedal, the electronically controlled air valve is energized. Make the high-pressure gas push the half-shaft clutch release lever 22, make the half-shaft clutch separate, and the engine and the drive axle are disengaged, thereby reducing the consumption of mechanical energy when the drive axle is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com