Two-rotor variable-cycle detonation piston engine

A piston engine and variable cycle technology, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of increased piston/cylinder liner wear, low integration of engine and motor, and high manufacturing difficulty, so as to reduce mechanical energy loss and system wear, The effect of improving the electromechanical coupling performance and reducing the difficulty of manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

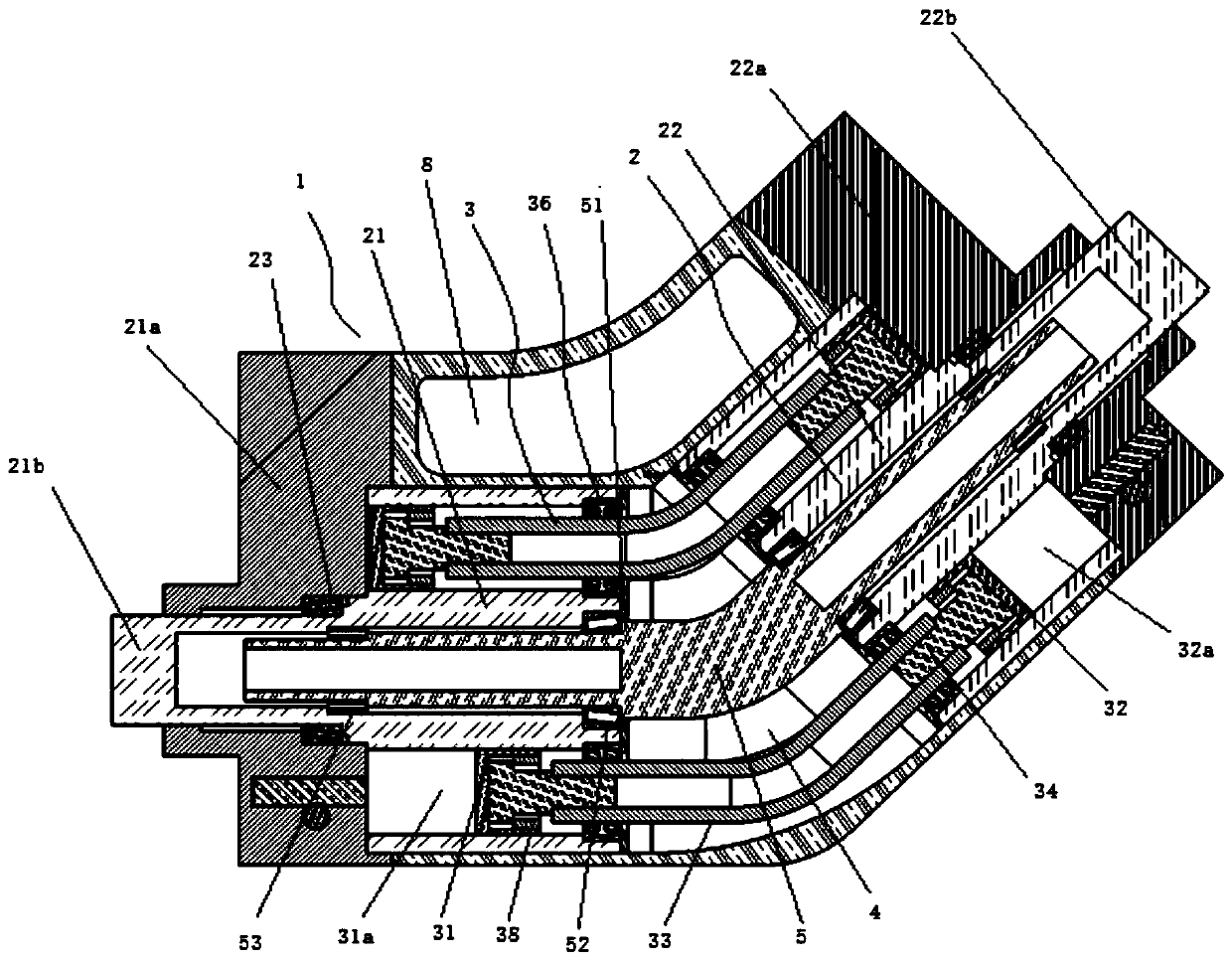

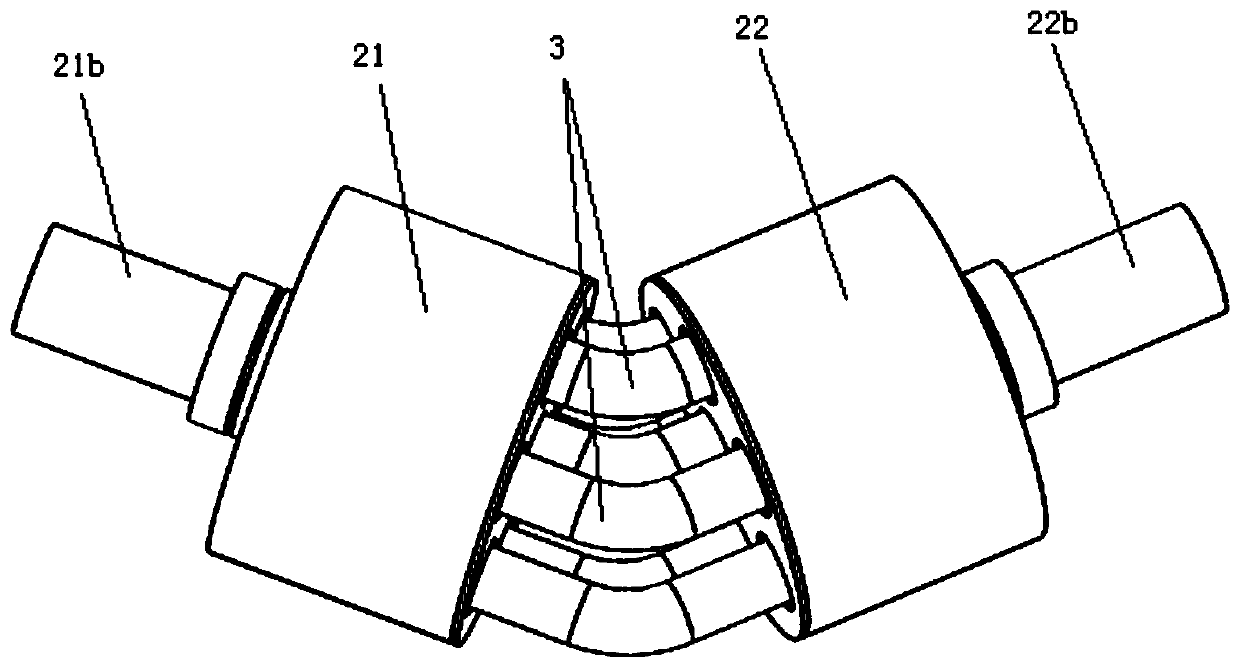

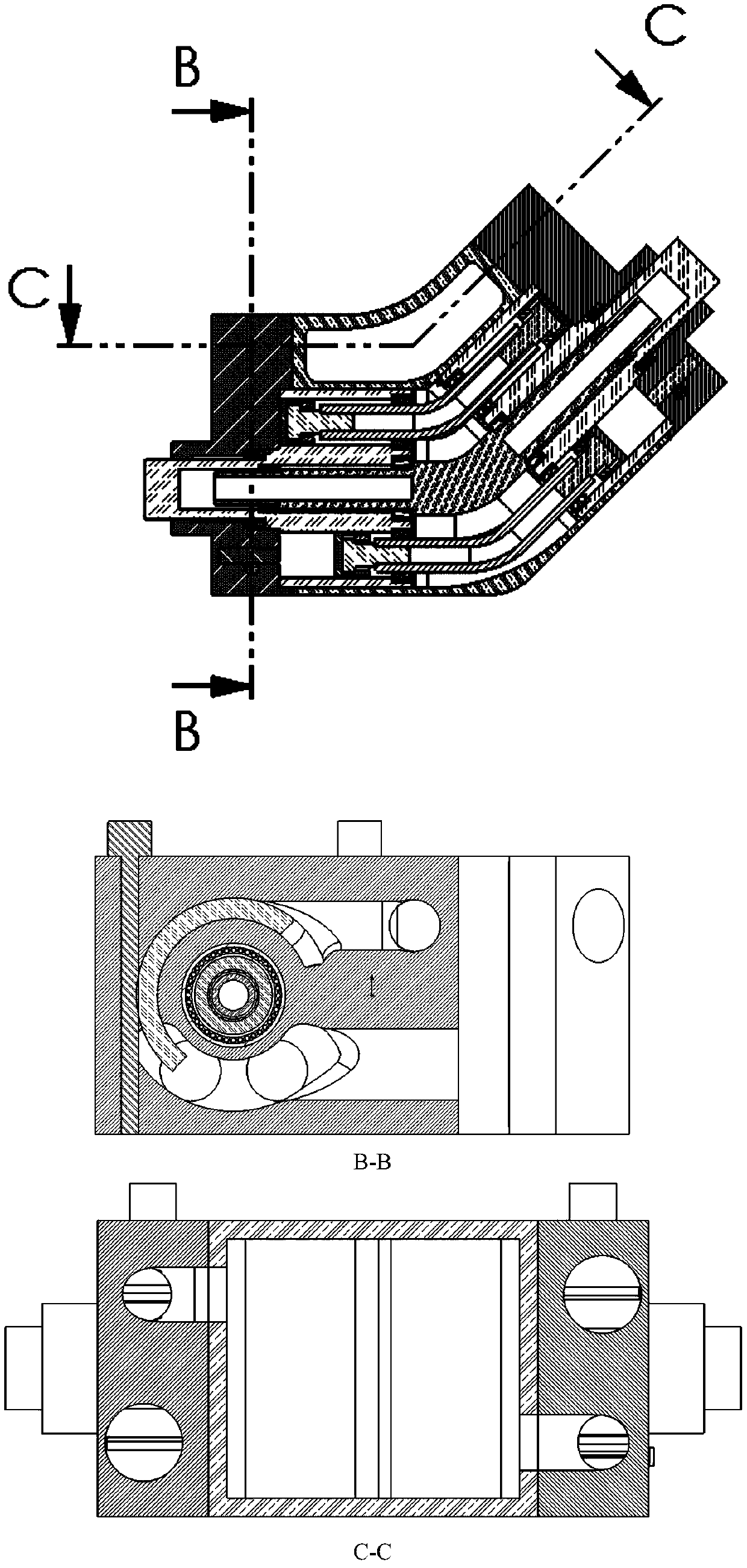

[0042]As shown in the figure, the dual-rotor variable-cycle deflagration piston engine in this embodiment includes a body, a rotor assembly, a piston assembly, a gas distribution mechanism, a high-pressure gas storage chamber, and an oil supply ignition mechanism; The rotor assembly 2 is a double-rotor structure, including a first rotor 21 and a second rotor 22, which are rotatably arranged at both ends of the V-shaped accommodation chamber 4. The first rotor and the second rotor are respectively eccentrically provided with a second rotor. A cylinder 31a and a second cylinder 32a; the piston assembly includes a first piston 31 arranged in the first cylinder, a second piston 32 arranged in the second cylinder and two ends fixedly connected to the first piston and the first piston respectively in the axial direction The second piston and the piston connecting rod 33 that cooperates with the corresponding cylinder through the cylinder pair, the piston connecting rod 33 is a V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com