Device for adjusting wall thickness of hot rolled steel tube

A technology for regulating devices and steel pipes, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the longitudinal wall thickness deviation of hot-rolled steel pipes, uneven wall thickness of hot-rolled seamless steel pipes, and longitudinal deviation of steel pipe wall thickness and other issues, to achieve the effect of improving the quality of steel pipes, increasing the yield of steel pipes, and increasing profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

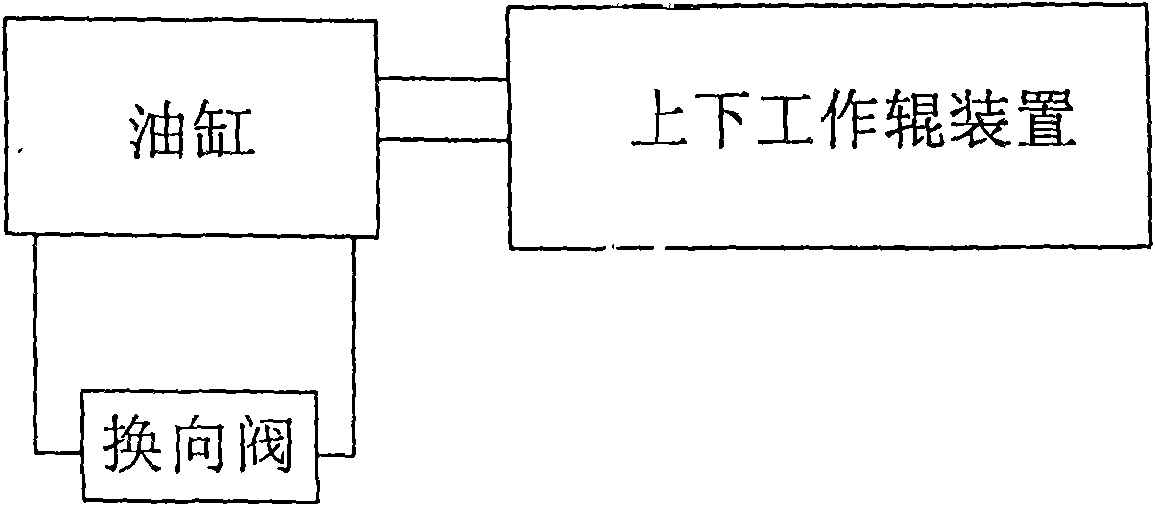

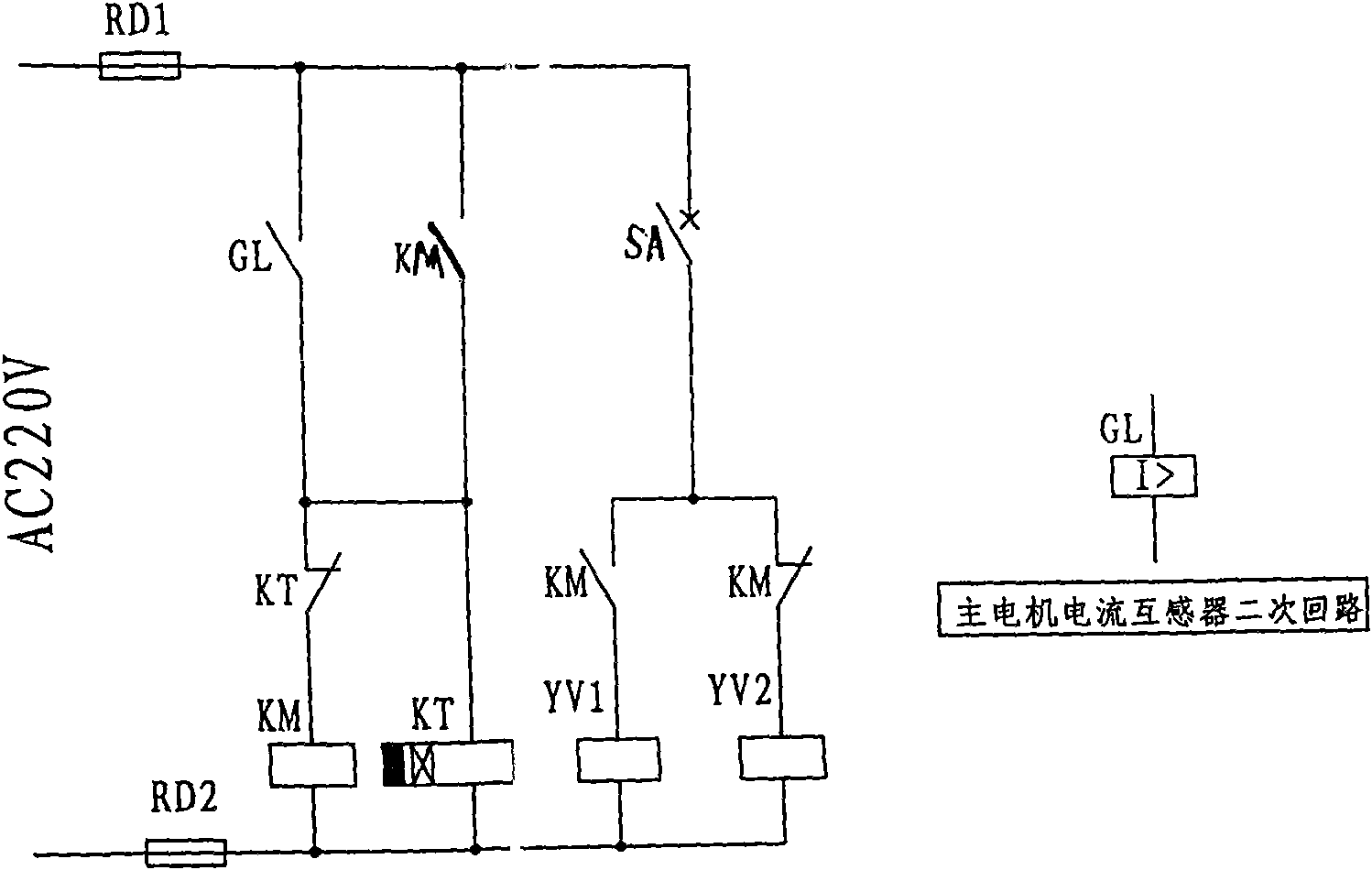

[0022] The invention includes an electric control device and a hydraulic device. The electric control device includes a current transformer arranged on a main motor of a rolling mill, an overcurrent relay, a time relay and an intermediate relay. When the pipe rolling mill starts rolling, the current of the main machine increases, the current transformer on the main motor of the rolling mill works, the over-current relay assists the electric shock to close, drives the coil of the intermediate relay to be energized and closed, and self-locks through the auxiliary contact. The directional valve YV1 is energized, the reversing valve YV2 is de-energized, and the oil cylinder operates to control the roll action and adjust the roll gap. At the same time, the time relay coil is energized. When the time exceeds the set value of the time relay, the auxiliary contact of the time relay is opened. Cut off the coil circuit of the time relay, at this time, the reversing valve YV1 is de-energi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com