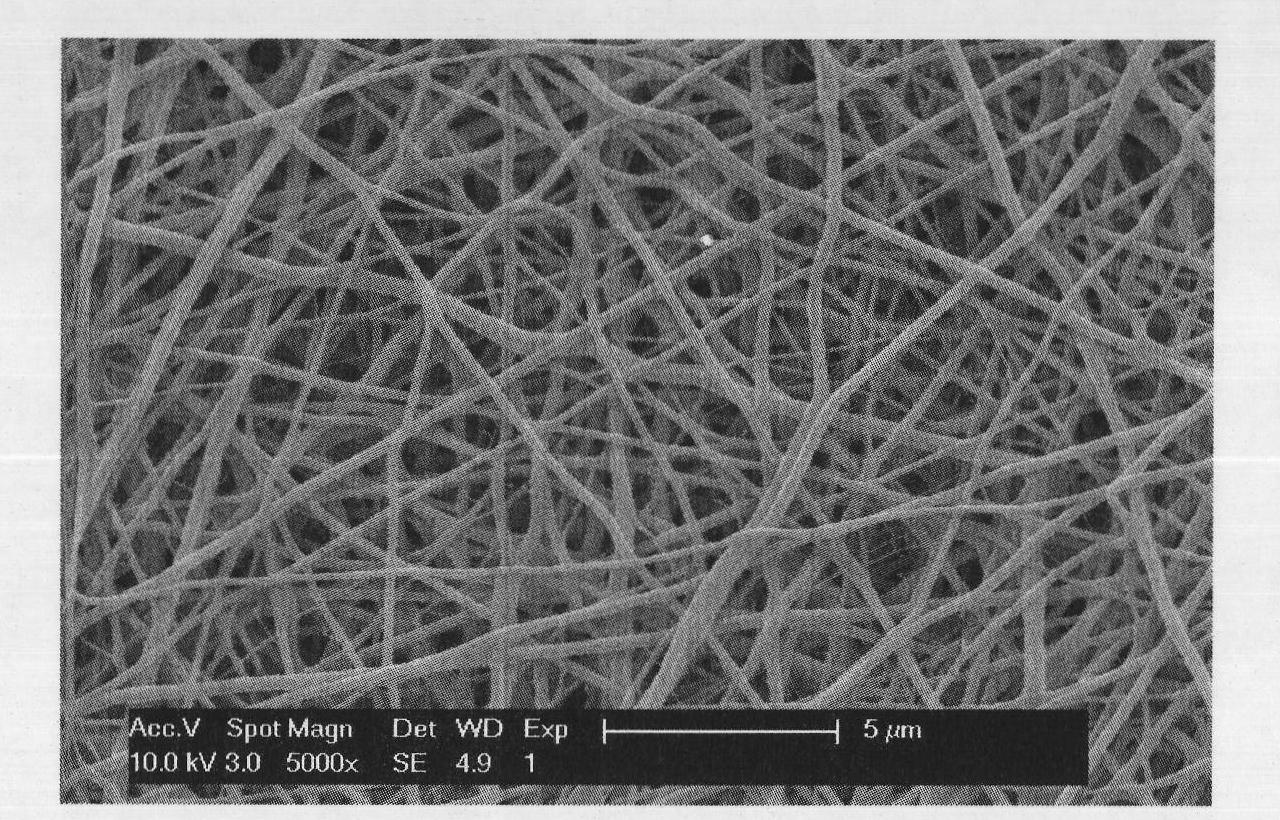

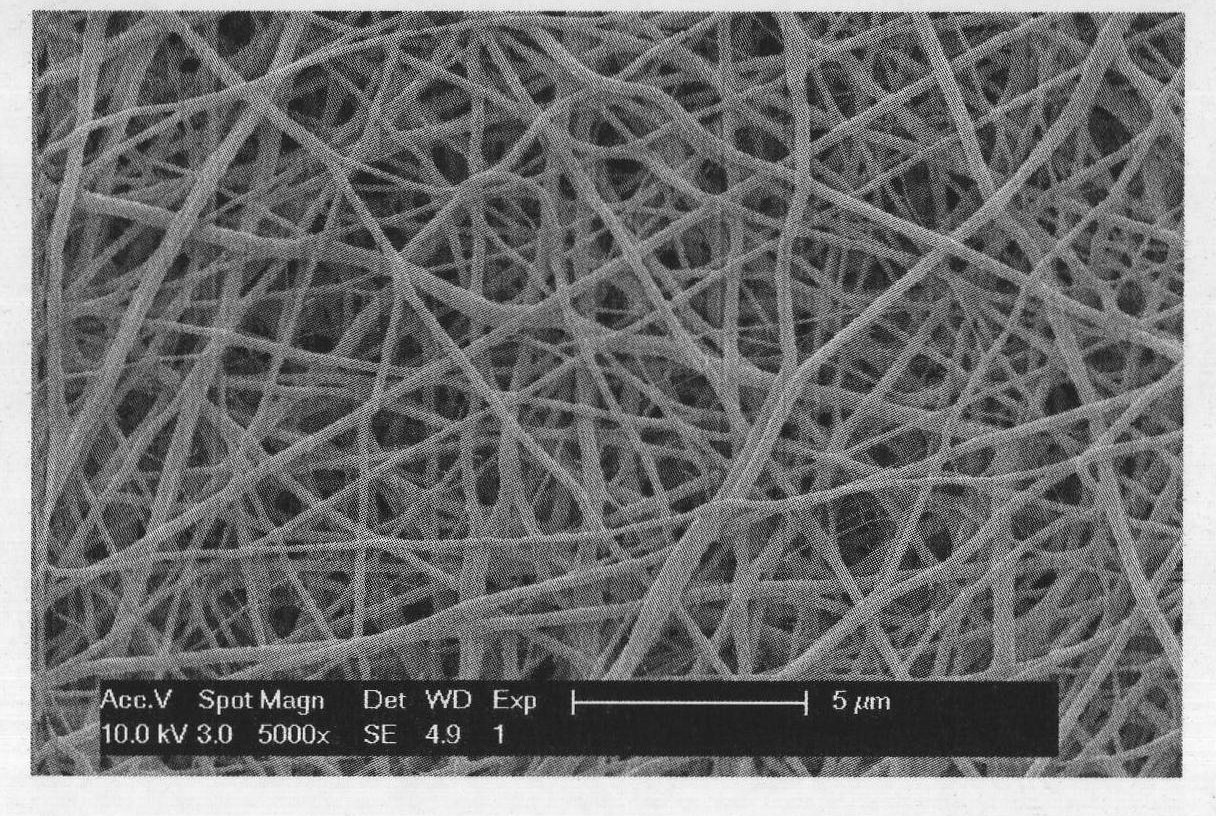

Three-dimensional porous nano-bracket based on fibrinogen and preparation method thereof

A fibrinogen, three-dimensional porous technology, applied in fiber processing, medical science, filament/thread forming, etc., to achieve the effect of easy secretion, favorable growth and migration, and good interstitial connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step: dissolving fibrinogen in a solvent mixed with hexafluoroisopropanol and 10×DMEM medium at a volume ratio of 9:1 to prepare a fibrin stock solution with a mass fraction of 100 mg / ml;

[0029] The second step: dissolving polylactic acid / polycaprolactone copolymer (the weight ratio of polylactic acid / polycaprolactone is 7: 3, molecular weight is 150,000) in hexafluoroisopropanol to prepare mass fraction is 8% Polylactic acid / polycaprolactone stock solution;

[0030] Step 3: Mix the fibrin stock solution with the polylactic acid / polycaprolactone stock solution at a volume ratio of 1:4, then add it to the same capacity tube of the electrospinning machine for electrospinning, and the spinning voltage is 2kv / spinning distance cm, spinning distance 12cm, spinning solution propulsion speed 3ml / h, obtain a diameter of 0.5cm on the receiving device (a steel pipe with a rotating speed of 500rpm and an outer diameter of about 0.5cm), and a length of a tubular three-d...

Embodiment 2

[0033] The first step: dissolving fibrinogen in a solvent mixed with hexafluoroisopropanol and 10×DMEM medium at a volume ratio of 9:1 to prepare a fibrin stock solution with a mass fraction of 80 mg / ml;

[0034] The second step: the polylactic acid / polycaprolactone copolymer (the weight ratio of polylactic acid / polycaprolactone is 5: 5, and molecular weight is 50,000) is dissolved in chloroform and is the polylactic acid of 5% by mass fraction / Polycaprolactone stock solution;

[0035]Step 3: Mix the fibrin stock solution with the polylactic acid / polycaprolactone stock solution at a volume ratio of 1:2, then add it to the same capacity tube of the electrospinning machine for electrospinning, and the spinning voltage is 0.5kv / spinning Distance cm, spinning distance 12cm, spinning solution propulsion speed 0.5ml / h, obtain a diameter of 0.5cm on the receiving device (a steel pipe with a rotating speed of 500rpm and an outer diameter of about 0.5cm), and a length of 10cm tubular ...

Embodiment 3

[0038] The first step: dissolving fibrinogen in a solvent mixed with hexafluoroisopropanol and 10×DMEM medium at a volume ratio of 9:1 to prepare a fibrin stock solution with a mass fraction of 120 mg / ml;

[0039] The second step: dissolving polylactic acid / polycaprolactone copolymer (the weight ratio of polylactic acid / polycaprolactone is 8: 2, molecular weight is 300,000) is dissolved in dimethylformamide and is 10% by mass fraction Polylactic acid / polycaprolactone stock solution;

[0040] Step 3: Mix the fibrin stock solution with the polylactic acid / polycaprolactone stock solution at a volume ratio of 1:1 and then add it to the same capacity tube of the electrospinning machine for electrospinning. The spinning voltage is 3kv / spinning distance cm, the spinning distance is 12cm, the spinning solution propulsion speed is 4ml / h, and a film-like three-dimensional porous nano-stent of 5cm×10cm is obtained on the receiving device (5cm×10cm flat steel plate);

[0041] The fourth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com