Repair-proof welded connection technology of inner walls of plastic-coated steel tubes

A technology for welding and connecting plastic-coated steel pipes, which can be applied to non-removable pipe connections, pipes/pipe joints/fittings, passing elements, etc., which can solve the problem of reducing the fluid cross-section of the inner wall of the steel pipe, the difficulty of popularizing and applying plastic-coated steel pipes, and the easy decomposition of the coating. and carbonization and other problems, to achieve the effect of reducing hidden operations and good technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

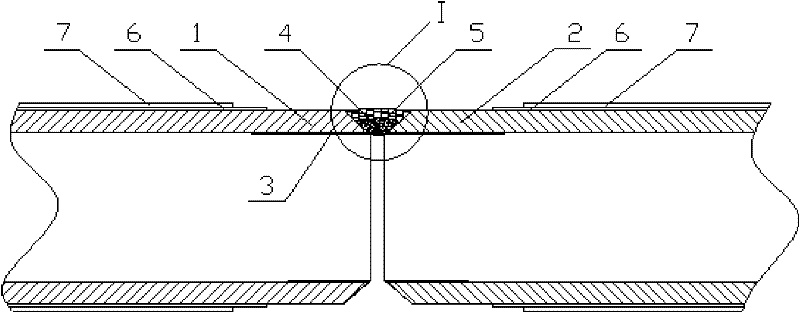

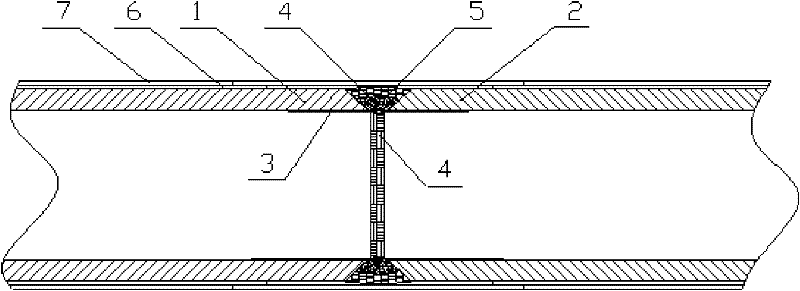

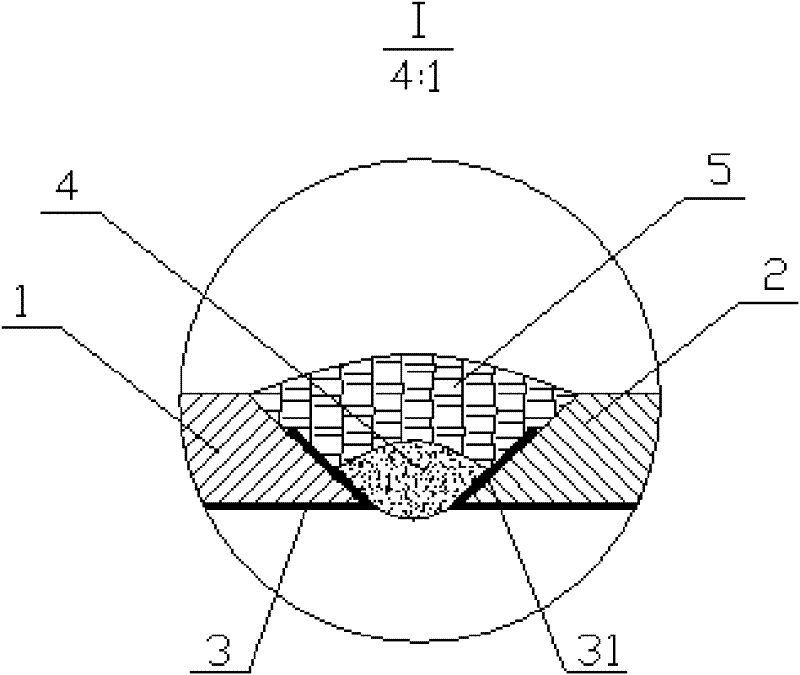

[0032] Repair-free welding connection process for the inner wall of plastic-coated steel pipes, such as Figure 1 to Figure 4 As shown, the welding connection process is as follows:

[0033] a. Derusting steel pipes 1 and 2;

[0034] b. Steel pipe 1, 2 port thermal spraying metal coating;

[0035] c. Make a thin-walled stainless steel sleeve 3;

[0036] d. Put the thin-walled stainless steel sleeve 3 into the steel pipes 1 and 2 and make the thin-wall stainless steel sleeve 3 tightly line the inner walls of the steel pipes 1 and 2 by expanding the tube;

[0037] e. The end of the thin-walled stainless steel sleeve 3 is turned over according to the shape of the cutout of the steel pipe 1 to form a flanging 31;

[0038] f. The inner and outer walls of steel pipes 1 and 2 are coated with step coatings 6 and 7;

[0039] g. Transport the steel pipes 1 and 2 covered with thin-walled stainless steel sleeves 3 to the site;

[0040] h. The thin-walled stainless steel sleeves 3 are...

Embodiment 2

[0052] Repair-free welding connection process for the inner wall of plastic-coated steel pipes, such as Figure 1 to Figure 4 As shown, the welding connection process is as follows:

[0053] a. Derusting steel pipes 1 and 2;

[0054] b. Steel pipe 1, 2 port thermal spraying metal coating;

[0055] c. Make a thin-walled stainless steel sleeve 3;

[0056] d. Put the thin-walled stainless steel sleeve 3 into the steel pipes 1 and 2 and make the thin-wall stainless steel sleeve 3 tightly line the inner walls of the steel pipes 1 and 2 by expanding the tube;

[0057] e. The end of the thin-walled stainless steel sleeve 3 is turned over according to the shape of the cutout of the steel pipe 1 to form a flanging 31;

[0058] f. The inner and outer walls of steel pipes 1 and 2 are coated with step coatings 6 and 7;

[0059] g. Transport the steel pipes 1 and 2 covered with thin-walled stainless steel sleeves 3 to the site;

[0060] h. The thin-walled stainless steel sleeves 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com