Prestressed hinge joint structure of prefabricated bridge deck slab of fully-assembled composite beam bridge and construction method of prestressed hinge joint structure

A prefabricated bridge and prestressed technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problem of affecting driving comfort and life of shear joints, low strength of the interface between new and old concrete, and difficulty in guaranteeing the quality of pouring and maintenance and other problems, to achieve the effect of saving maintenance time, simplifying the construction operation process, and facilitating quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

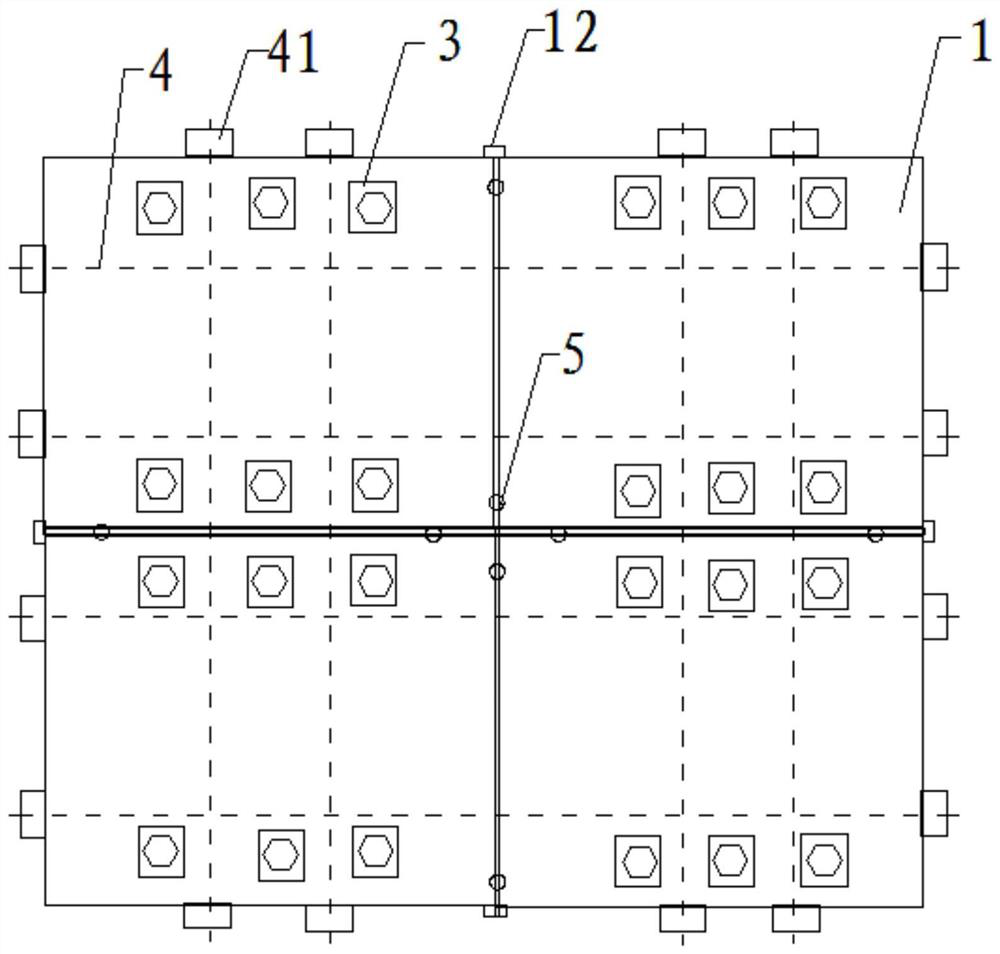

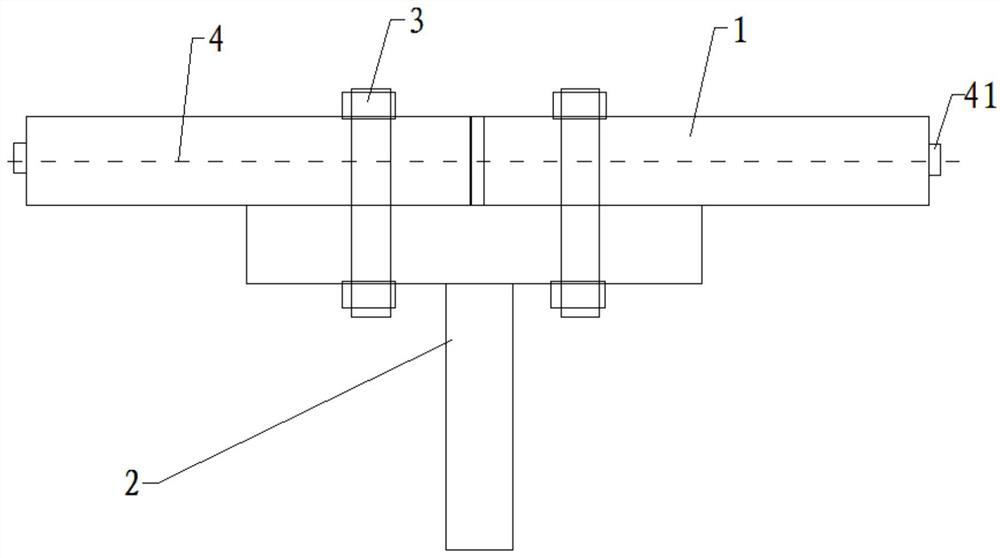

[0041] As shown in the figure, a prefabricated bridge deck prestressed joint structure of a fully assembled composite girder bridge includes a prefabricated bridge deck 1 with holes, and the adjacent prefabricated bridge decks 1 with holes are connected by a prestressing system. Cables 4 and anchors 41, the prestressed cables 4 are passed between the prefabricated bridge decks 1 with holes, and the anchors 41 are located at both ends of the prestressed cables 4.

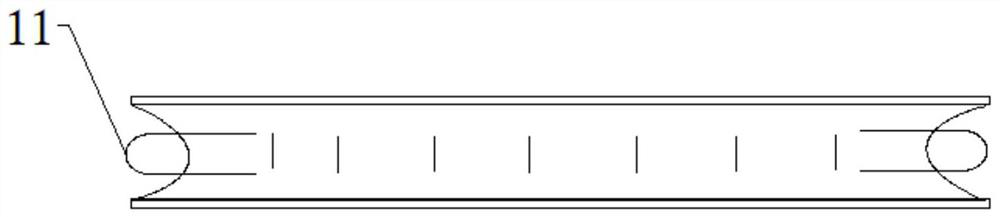

[0042] The boundary of the perforated prefabricated bridge deck 1 is provided with vertical reserved holes, and U-shaped notches are arranged around the perforated prefabricated bridge deck 1, and the U-shaped notch is preset with annular steel bars 11. Longitudinal steel bars are arranged at the superposition of the annular steel bars 11 between them, which can further strengthen the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com