Manufacturing process of composite textile

A manufacturing process and textile technology, applied in the field of composite textile manufacturing process, can solve problems such as waterproof and moisture permeability, limited application fields, and poor product comfort, and achieve convenient operation, wide application range, and compact fabric structure solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

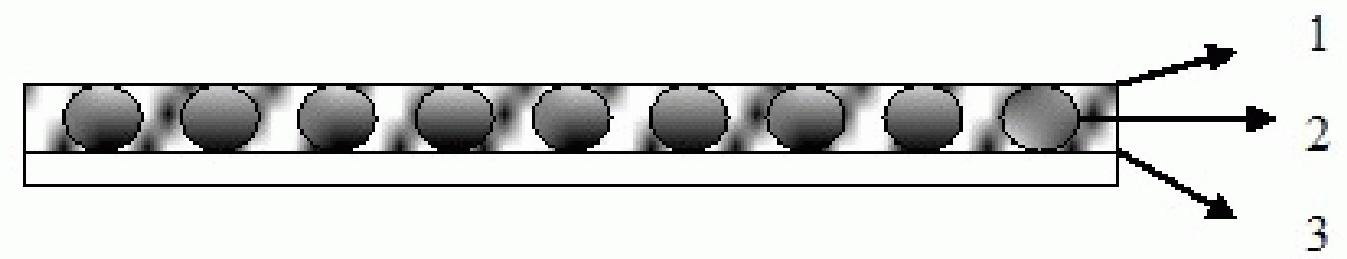

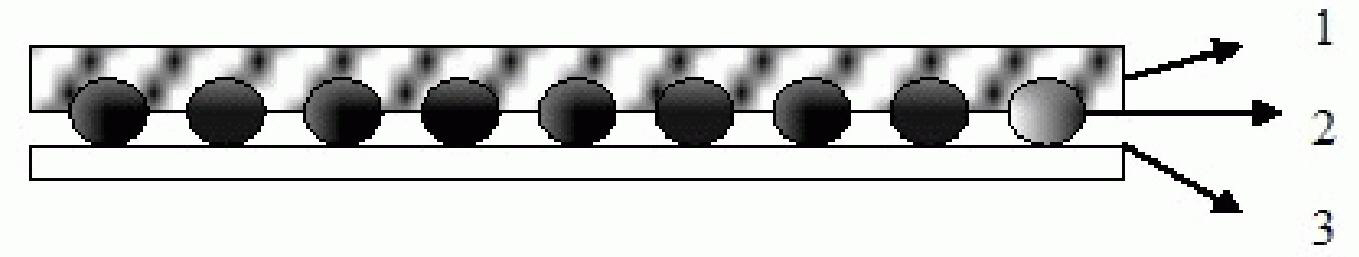

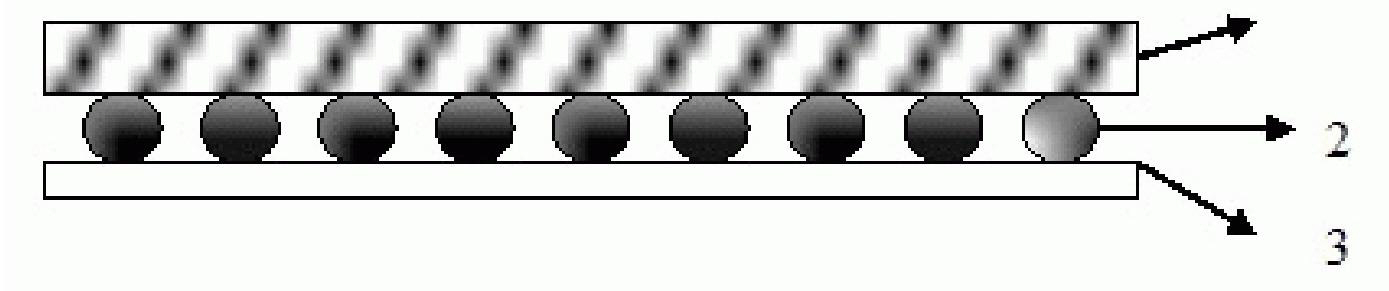

Image

Examples

Embodiment 1

[0020] Example 1: A manufacturing process of composite textiles, using pure cotton textiles as the base material, preheating the textile base material: flattening the pure cotton textiles and preheating, the preheating temperature is 40°C-50°C; select TPU with hydrophilic function The film is the auxiliary base material, the thickness of the TPU hydrophilic functional film is 20-30 μm, and the auxiliary base material functional film is flattened; select and heat the moisture-curing hot melt adhesive: select BOSI9224 moisture-curing hot melt adhesive, the glass transition temperature is less than 20 ℃ Moisture-curing hot-melt adhesive, heating the moisture-curing hot-melt adhesive to a temperature of 60°C-100°C, and a viscosity of 4000-8000mpas; coating of hot-melt adhesive: coating the hot-melt adhesive on the auxiliary substrate TPU hydrophilic functional film, coating Cloth weight 25g / m 2 , the coating gap is -0.5-1mm,; lamination fusion: the pure cotton textile substrate an...

Embodiment 2

[0022] Example 2: A composite textile, with chemical fiber polyester textile fabric as the base material, the chemical fiber polyester textile fabric is flattened and preheated, the preheating temperature is 35°C-45°C; PTFE microporous functional membrane is used as the auxiliary substrate, PTFE The thickness of the microporous functional film is 40-60 μm, flatten the PTFE microporous functional layer, select SIKA9640 moisture-curing hot melt adhesive, the glass transition temperature is 20°C40°C, the moisture-curing hot melt adhesive is heated to a temperature of 80°C-120°C, and the viscosity is 8000-10000mpas, hot melt adhesive is coated on the PTFE microporous functional layer, the coating weight is 5-25g / m 2 , Coating gap -0.5-1mm; The pure polyester textile fabric and the PTFE microporous functional layer are laminated and fused, the lamination gap is 0.1-0.4mm, the lamination temperature is 30°C-40°C, and then winding, flat and natural curling pressure 3bar, put it in an...

Embodiment 3

[0025] Example 3: A composite textile, using ordinary woolen textile fabric as the base material, flattening the woolen textile fabric for preheating, the preheating temperature is 30°C-40°C, using PU hydrophilic functional film as the auxiliary substrate, PU hydrophilic The thickness of the water functional film is 10-20μm, select BOSI9216 moisture-curing hot melt adhesive, the glass transition temperature is greater than 40°C, the heating temperature of the moisture-curing hot melt adhesive is 80°C-100°C, and the viscosity is 10000-15000mpas, and the hot melt adhesive is coated on On the PU hydrophilic functional layer, the coating weight is 5-25g / m 2 , Coating gap -0.5-1mm; The woolen textile fabric and the PU hydrophilic functional film are laminated and fused, the lamination gap is 0.3-3mm, and the lamination temperature is 40°C-50°C. Flatten and naturally curl with a pressure of 2bar, and cure for 7 days in an environment with a temperature of 25°C and a humidity of 50%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com