Polyethylene recyclable isolation film for tire production

A high-molecular polyethylene and high-density polyethylene technology, which is applied in the production field of radial tires, can solve the problems of increased resource development, soft tire structure, and large usage, and achieves a scientific melting process, good molding performance, and durability light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following examples are used to further illustrate the present invention and enhance understanding of the present invention, but the present invention should not be construed as being limited to the description of the following examples.

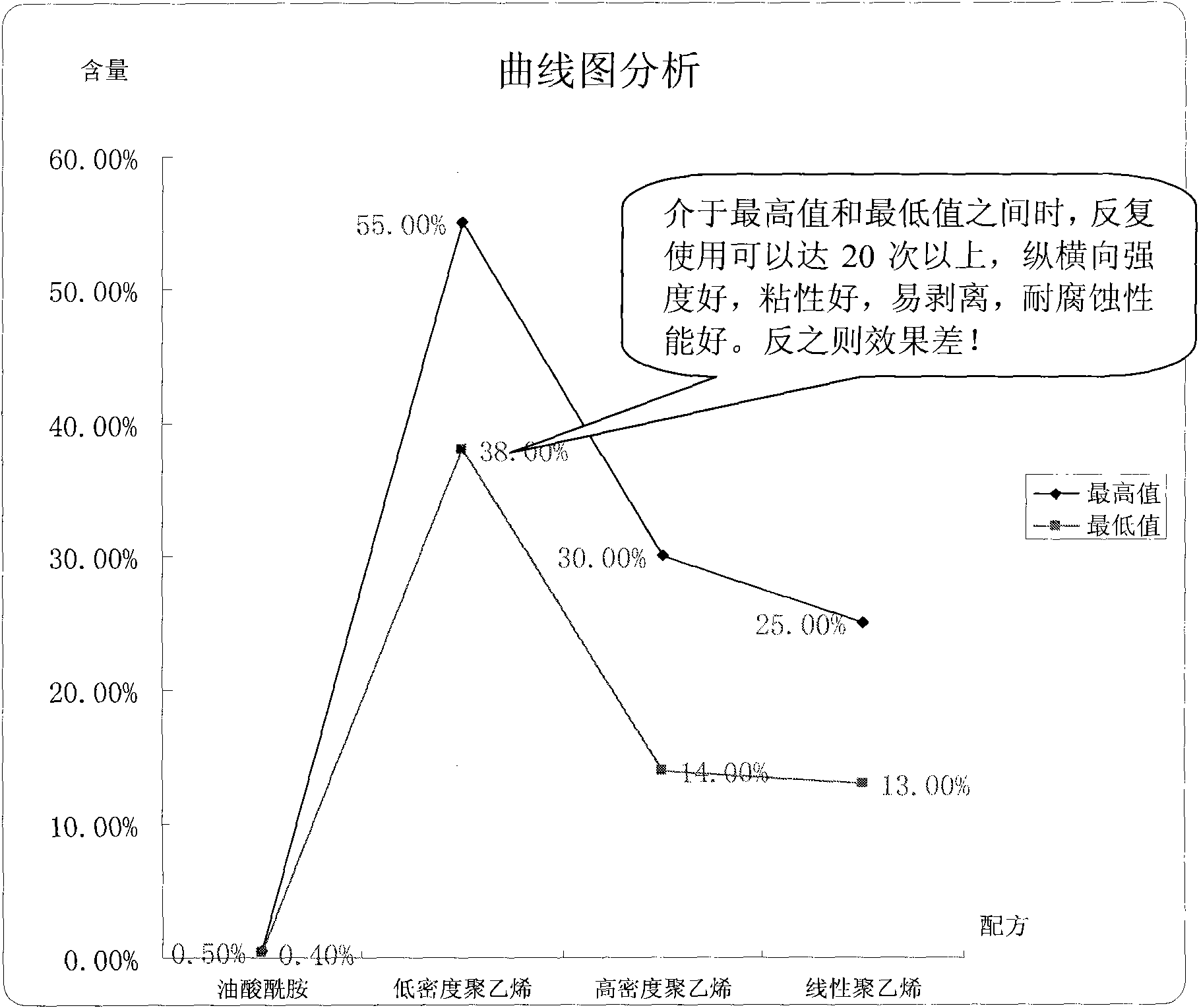

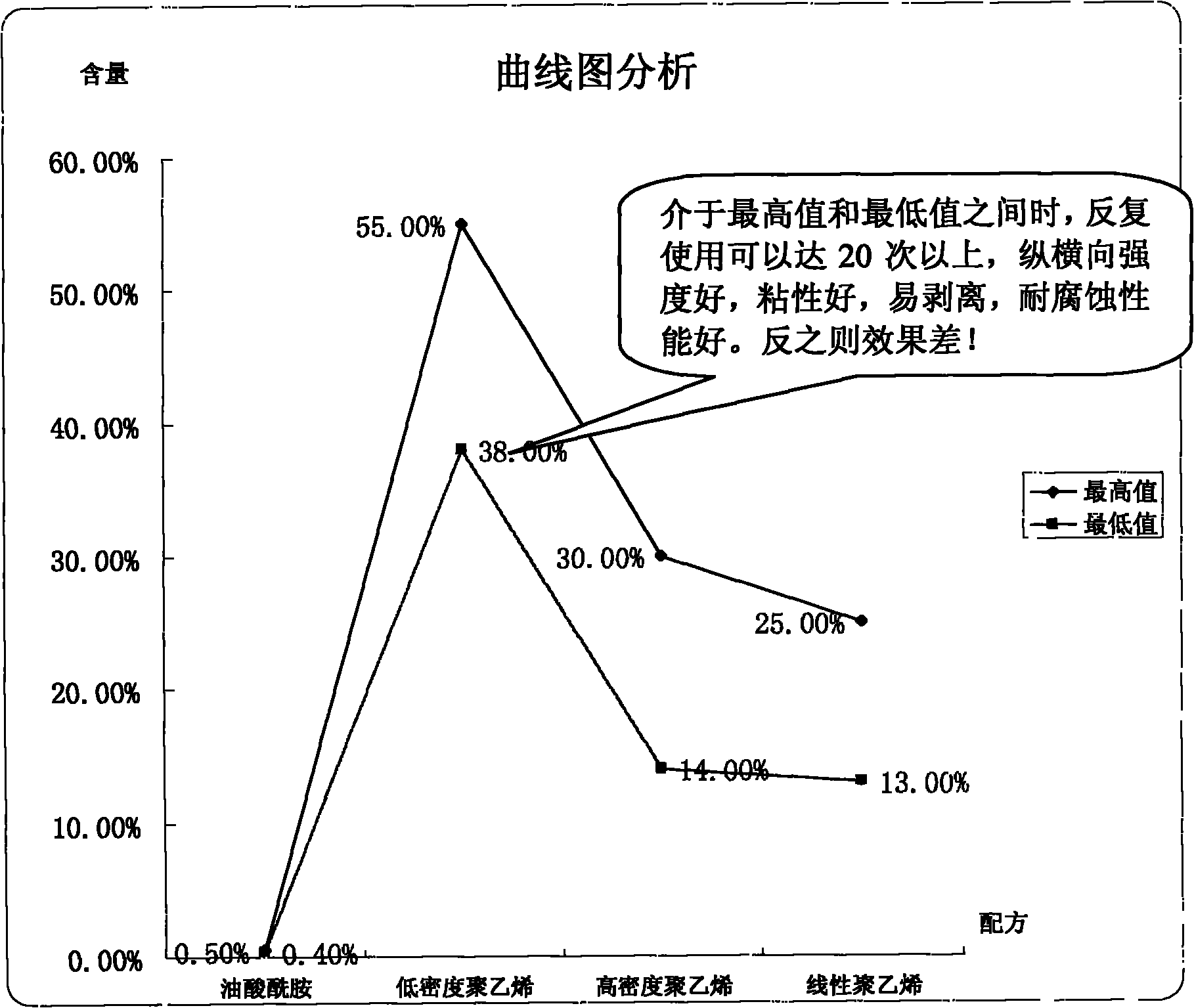

[0059] 1: Low-density polyethylene 26%, ultra-low-density polyethylene 19%, high-density polyethylene 20%, linear low-density polyethylene 17%, film ethylene EMAA 12.4%, oleic acid amide 0.6%, plasticizer 0.8 %, multifunctional additives 4.2%.

[0060] 2: Low-density polyethylene 27%, ultra-low-density polyethylene 15%, high-density polyethylene 20%, linear low-density polyethylene 19%, film ethylene EMAA 14%, oleic acid amide 0.6%, plasticizer 0.5%, Multifunctional Auxiliary 3.9%.

[0061] 3: Low-density polyethylene 22%, high-density polyethylene 18%, linear low-density polyethylene 18%, oleic acid amide 0.7%. 22% ultra-low density polyethylene, 15% ethylene EMAA for film, 1% plasticizer, and 3.3% multifunctional additives.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com