Fluorine silicon resin, preparation method thereof and antifouling paint

A technology of fluorosilicone resin and anti-fouling coatings, which is applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc. It can solve the problems of mixing solvents for a long time, agglomeration and precipitation of inorganic particles, and storage period of coatings. Short and other problems, to achieve the effect of high strength and hardness, lower surface energy, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

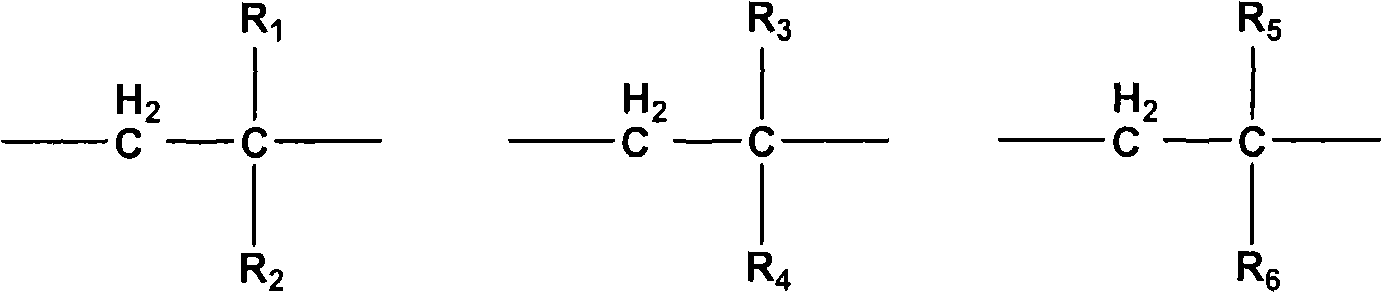

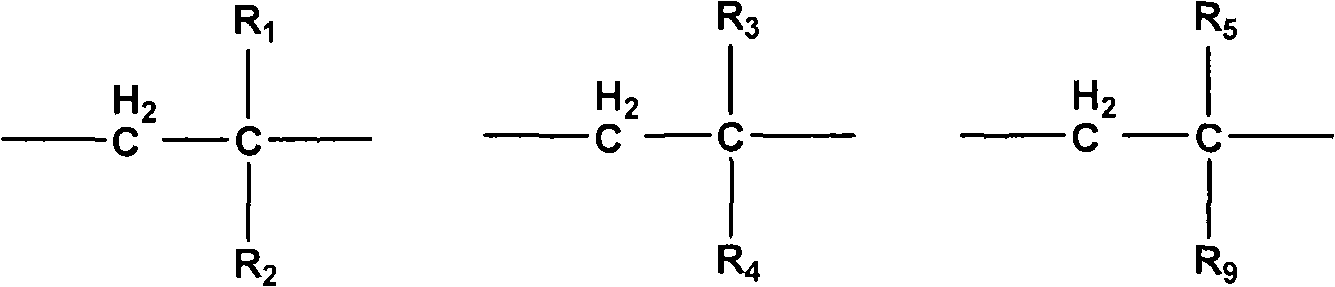

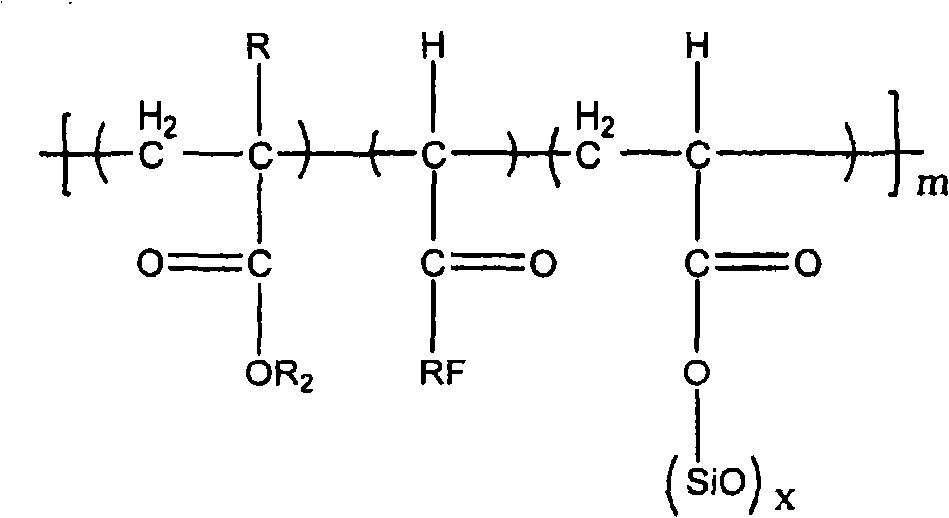

[0034] The present invention also provides the preparation method of the above-mentioned fluorosilicone resin, which comprises contacting the fluoropolymer and silicate and / or alkoxysilane with water to carry out hydrolysis and condensation reaction, the molecular chain of the fluoropolymer The side group contains isobornyl group and / or acetoacetoxyethyl group, alkyl group and / or ester group containing fluorine atom, and siloxane group bonded to the main chain of fluorine-containing polymer.

[0035] The conditions of the hydrolysis condensation reaction include: the weight of the fluoropolymer: the total weight of silicate and alkoxysilane: the weight of water is 1: 0.1-0.4: 0.03-0.09; The temperature may be 10-60° C., and the time for the hydrolysis and condensation reaction may be 2-24 hours.

[0036] The hydrolysis condensation reaction can be carried out in a first solvent, and the first solvent can be a solvent commonly used in the art, for example: in methanol, ethanol,...

Embodiment 1

[0087] This example is used to illustrate the fluorosilicone resin of the present invention and its preparation method.

[0088] Mix 54g isobutyl methacrylate, 6g isobornyl methacrylate, 20g brand 567A perfluoroalkyl acrylate, 20g methacryloxypropyltriethoxysilane in methyl ethyl ketone and m-xylene Carry out solution polymerization in the solvent, solvent amount is methyl ethyl ketone 80g, m-xylene 160g respectively, initiator is azobisisobutyronitrile (AIBN), with the total amount of polymerizable monomer as a benchmark, the amount of AIBN is 2% by weight, The reaction temperature is 80°C, and the reaction time is 12 hours. Afterwards, the obtained mixed solution is spin-dried in a rotary evaporator to remove the solvent. It is confirmed by infrared spectroscopy that the residue is the isoborneol contained in the side group of the molecular chain described in the present invention. Fluoropolymers with groups, ester groups containing fluorine atoms, and siloxane groups bonded...

Embodiment 2

[0091] This example is used to illustrate the fluorosilicone resin of the present invention and its preparation method.

[0092] 50g methyl methacrylate, 10g isobornyl methacrylate, 20g brand 567A perfluoroalkyl acrylate, 20g methacryloxypropyltrimethoxysilane were carried out in a mixed solvent of methyl ethyl ketone and toluene Solution polymerization, the amount of solvent is respectively 100g of methyl ethyl ketone, 200g of toluene, the initiator is AIBN, based on the total amount of polymerizable monomers, the amount of AIBN is 2% by weight, the reaction temperature is 80°C, and the reaction time is 12h. The resulting mixed solution is spin-dried in a rotary evaporator to remove the solvent, and the residue is confirmed by infrared spectroscopic analysis that the side group of the molecular chain of the present invention contains isobornyl, fluorine-containing ester groups, and fluorine-containing Fluoropolymers with siloxane groups bonded to the polymer backbone. The nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com