Spherical manganese dioxide and its preparation method

A manganese dioxide, spherical technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of insufficient particle size, increase the content of elemental iron in manganese dioxide powder, uneven appearance of manganese dioxide powder, etc., and achieve product impurities Low cost, low cost, excellent electrochemical charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

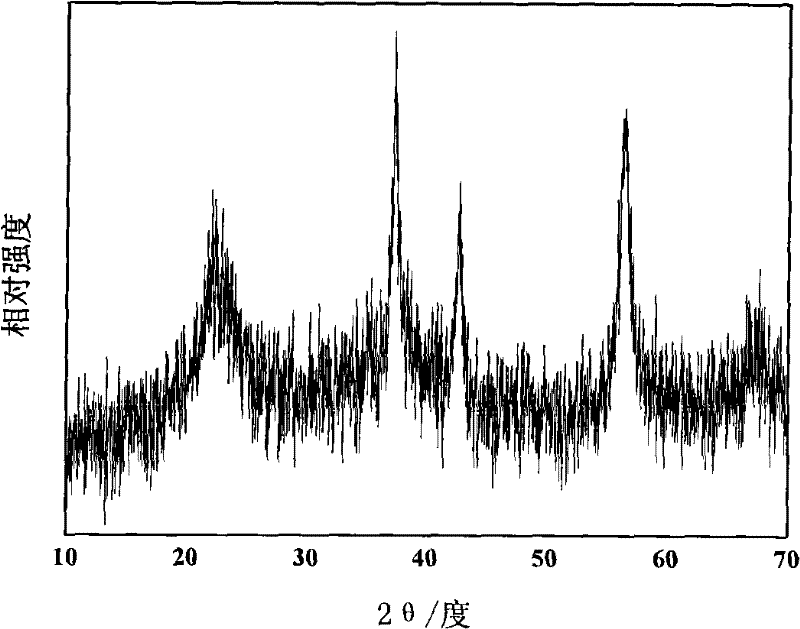

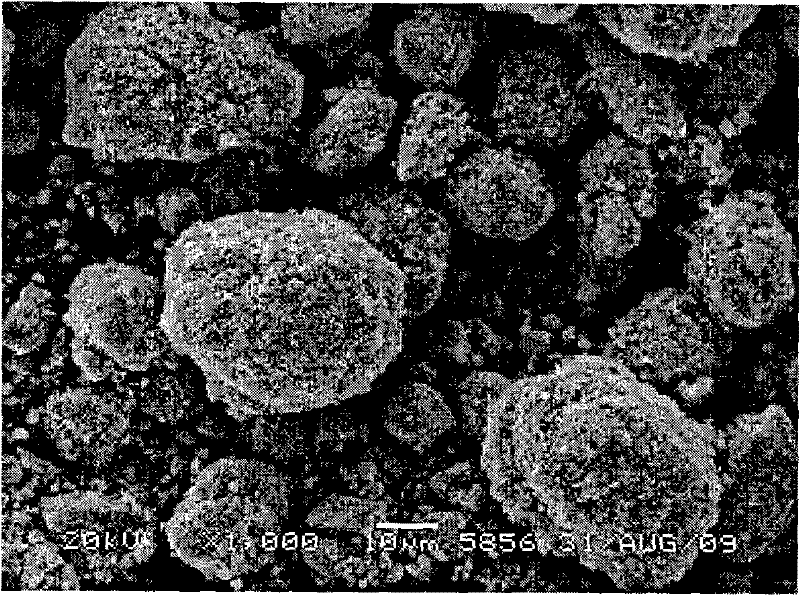

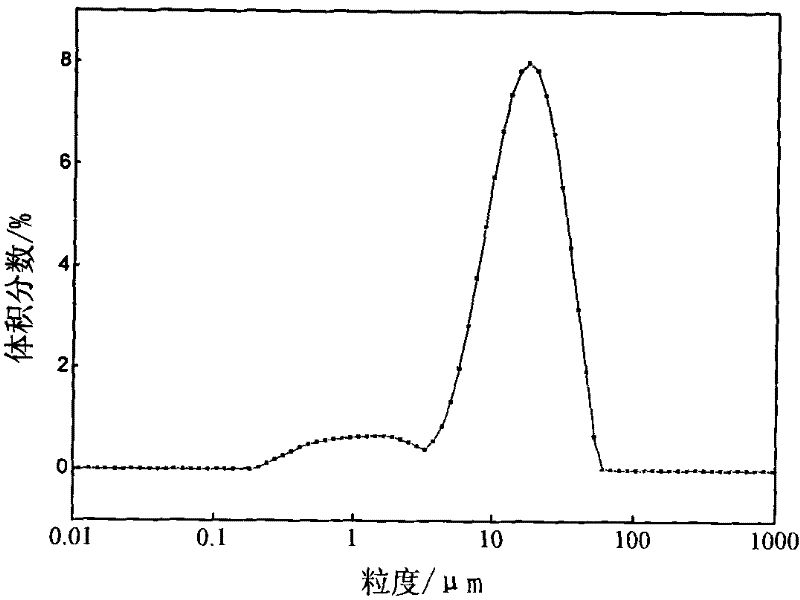

[0032] a kind of like Figure 1 ~ Figure 3 The spherical-like manganese dioxide shown in the present invention has a median particle size of 18.5 μm, has a γ-type crystal structure microscopically, and has a Fe content of 26 ppm.

[0033] The quasi-spherical manganese dioxide of the present embodiment is mainly prepared by the following methods:

[0034] Weigh 40kg of the manganese dioxide crude product after electrolysis, and use the jaw crusher to crush the manganese dioxide crude product after electrolysis in the first step. After the first step of crushing, manganese dioxide with an average diameter of about 11.5mm is obtained Coarse particles; then use the roller crusher to carry out the second step of crushing the manganese dioxide coarse particles after the first step of crushing, and after the second step of crushing, obtain the manganese dioxide fine particles with an average diameter of about 500 μm; The manganese dioxide fine particles after the roll are evenly add...

Embodiment 2

[0037] a kind of like Figure 4 ~ Figure 6 The spherical-like manganese dioxide shown in the present invention has a median particle size of 15 μm, has a γ-type crystal structure microscopically, and has a Fe content of 25 ppm.

[0038] The quasi-spherical manganese dioxide of the present embodiment is mainly prepared by the following methods:

[0039] Weigh 30kg of the manganese dioxide crude product after electrolysis, and use a jaw crusher to crush the manganese dioxide crude product after electrolysis in the first step. After the first step of crushing, manganese dioxide with an average diameter of about 12.0mm is obtained. Coarse particles; then use the roller crusher to carry out the second step of crushing the manganese dioxide coarse particles after the first step of crushing, and after the second step of crushing, obtain the manganese dioxide fine particles with an average diameter of about 500 μm; The manganese dioxide fine particles after the roll are evenly added to...

Embodiment 3

[0042] a kind of like Figure 7 ~ Figure 9 The spherical-like manganese dioxide shown in the present invention has a median particle size of 5 μm, has a γ-type crystal structure microscopically, and has a Fe content of 28 ppm.

[0043] The quasi-spherical manganese dioxide of the present embodiment is mainly prepared by the following methods:

[0044] Weigh 30kg of the manganese dioxide crude product after electrolysis, and use the jaw crusher to crush the manganese dioxide crude product after electrolysis in the first step. After the first step of crushing, manganese dioxide with an average diameter of about 13.0mm is obtained Coarse particles; then utilize the roller crusher to carry out the second step of crushing the manganese dioxide coarse particles after the first step of crushing, after the second step of crushing, obtain the manganese dioxide fine particles with an average diameter of 300 μm; The manganese dioxide fine particles after the roll are evenly added to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com