Method for preparing graphite alkyne film

A graphdiyne and thin film technology is applied in the field of preparing graphdiyne thin films to achieve the effects of simple process and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

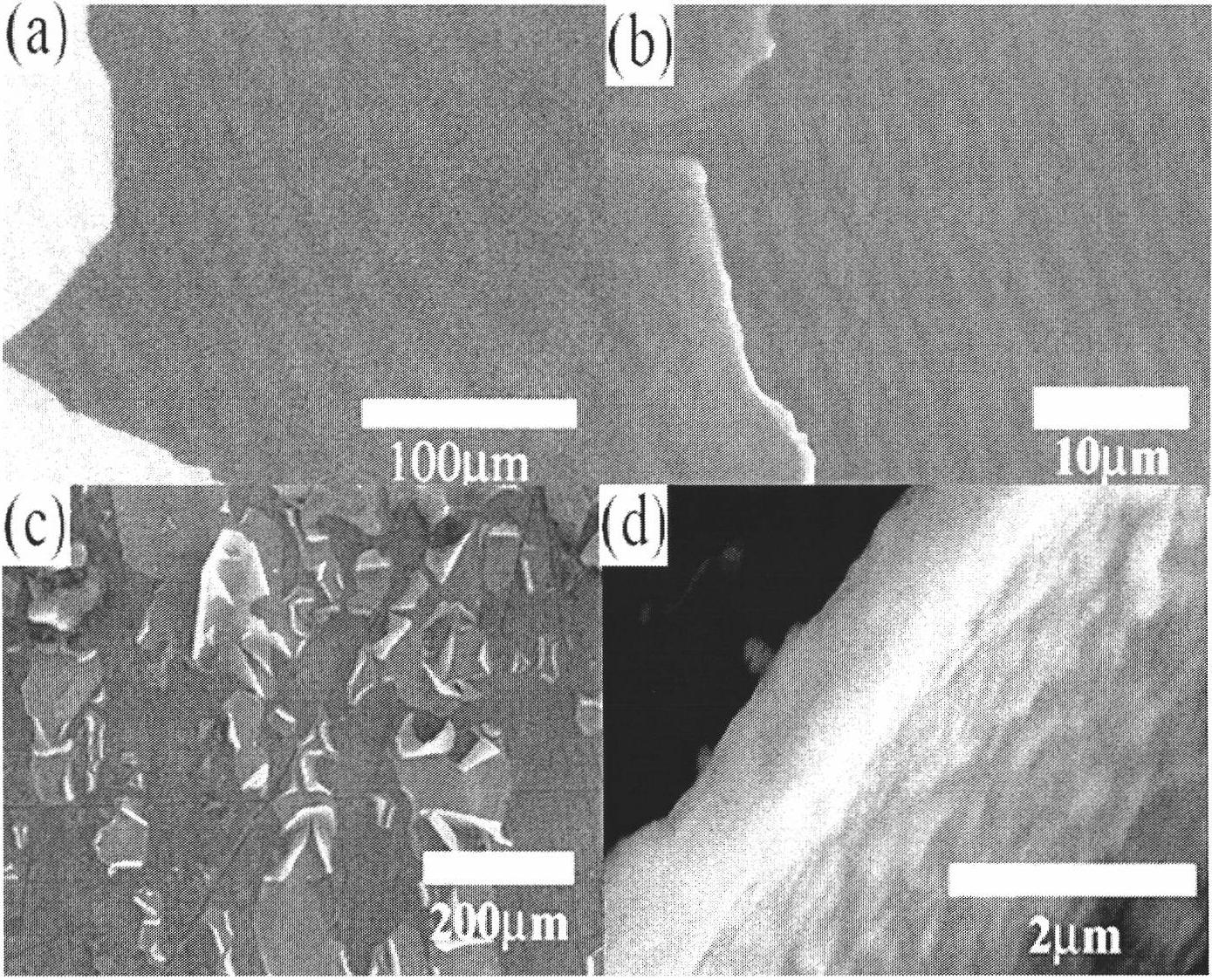

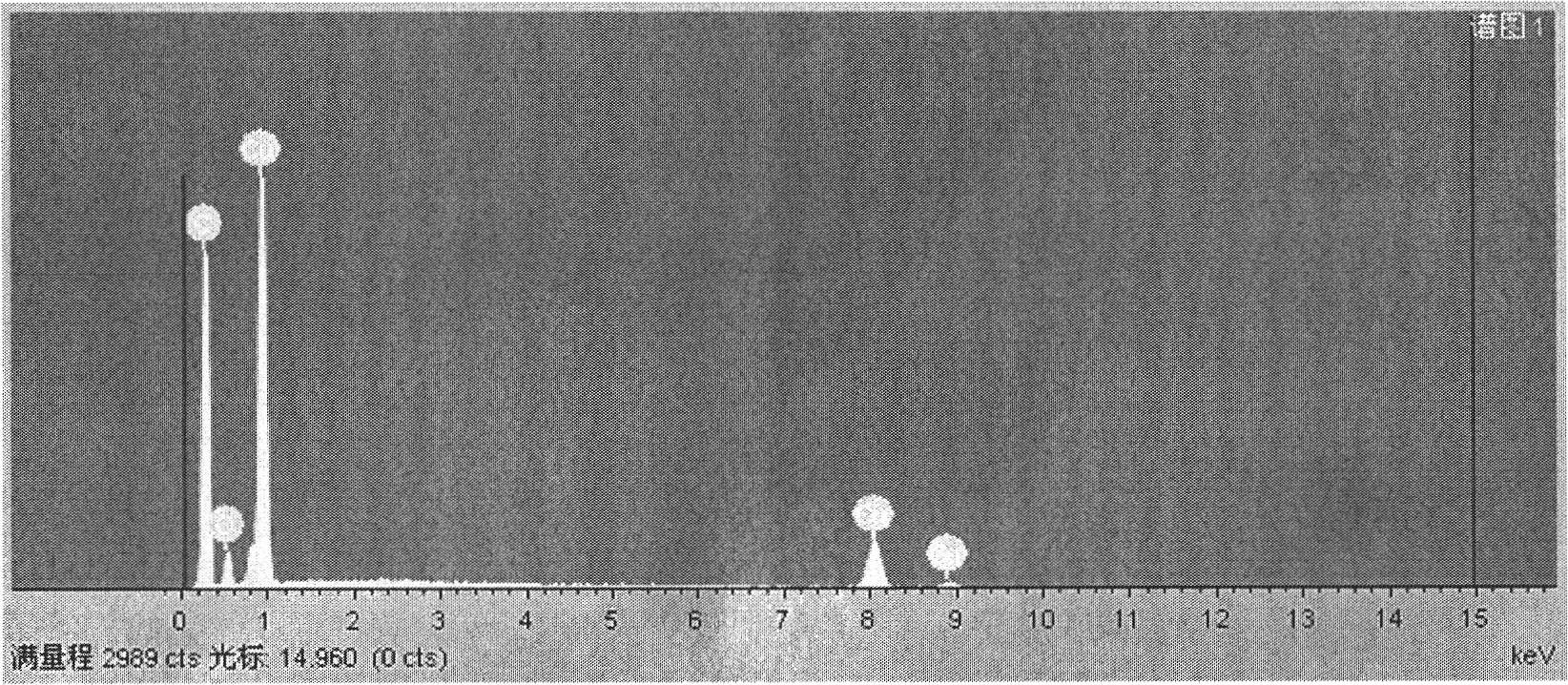

Embodiment 1

[0028] At 8°C, 0.4 ml of tetrabutylammonium fluoride (TBAF) (1 mol / L (M) tetrahydrofuran solution, 0.4 mmol), stirred and reacted for 10 minutes under nitrogen protection. Afterwards, the reaction solution was diluted with ethyl acetate (20 mL), washed three times with saturated brine, dried over anhydrous sodium sulfate (10 g), and concentrated to dryness to give hexaynylbenzene (compound 2) (9.08 mg, 62%). Dissolve compound 2 with 25ml of pyridine, and slowly add it dropwise to a three-neck flask filled with 50ml of pyridine (pyridine) and copper foil (copper foil, 4 square centimeters) under nitrogen protection (the temperature of the reaction solution is 60°C), and the time for adding for 24 hours. The stirring reaction was then continued at 60°C for 3 days. After the reaction finishes, a black film is formed on the copper sheet, and the copper sheet is washed with acetone and N,N-dimethylformamide (DMF) successively. This black film is a graphyne film (2.7mg, 24.3%). T...

Embodiment 2

[0038] At 8°C, 0.4 ml of tetrabutylammonium fluoride (TBAF) (1 mol / L (M) tetrahydrofuran solution, 0.4 mmol), stirred and reacted for 10 minutes under nitrogen protection. Afterwards, the reaction solution was diluted with ethyl acetate (20 mL), washed three times with saturated brine, dried over anhydrous sodium sulfate (10 g), and concentrated to dryness to give hexaynylbenzene (compound 2) (9.08 mg, 62%). Dissolve compound 2 with 25ml of pyridine, and slowly add it dropwise to a three-neck flask containing 50ml of pyridine and copper foil (4 square centimeters) under nitrogen protection (the temperature of the reaction solution is 50°C), and the time for adding for 24 hours. The stirring reaction was then continued at 50°C for 3 days. After the reaction finishes, a black film is formed on the copper sheet, and the copper sheet is washed with acetone and N,N-dimethylformamide (DMF) successively. This black film is graphyne thin film (1.3mg, 11.7%). Under this condition, t...

Embodiment 3

[0040] At 8°C, 0.4 ml of tetrabutylammonium fluoride (TBAF) (1 mol / L (M) tetrahydrofuran solution, 0.4 mmol), stirred and reacted for 10 minutes under nitrogen protection. Afterwards, the reaction solution was diluted with ethyl acetate (20 mL), washed three times with saturated brine, dried over anhydrous sodium sulfate (10 g), and concentrated to dryness to give hexaynylbenzene (compound 2) (9.08 mg, 62%). Dissolve compound 2 with 25ml of pyridine, and slowly add it dropwise to a three-neck flask filled with 50ml of pyridine (pyridine) and copper foil (copper foil, 4 square centimeters) under nitrogen protection (the temperature of the reaction solution is 80°C), and the time for adding for 24 hours. The stirring reaction was then continued at 80°C for 3 days. After the reaction finishes, a black film is formed on the copper sheet, and the copper sheet is washed with acetone and N, N-dimethylformamide (DMF) successively. This black film is graphyne thin film (2.0mg, 18.2%)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com